Introduction

Stucco over CMU block is a thin cement-based finish applied over masonry that needs a good bond, a proper scratch key, and planned crack control to last. Bonding agents, scratch coats, and reinforcement help the stucco grip the block and manage movement, but check product labels and local rules for compatibility and required curing times. I’ll describe practical ways to test adhesion, build an effective scratch key, and reduce cracks without inventing specs you must confirm.

Think like a foreman: inspect the block, pick a bonding approach that your materials support, and plan for control joints and reinforcement before you mix. Use mixes, sand blends, and additives recommended by manufacturers and apply by hand or spray with consistent technique while monitoring quality control as you go.

Key takeaways

- Verify bonding agent compatibility with CMU and plaster, follow manufacturer instructions.

- Conduct adhesion checks and document cure environments for reliable results.

- Use specialized stucco products to boost crack resistance and bond across CMU.

- Optimize sand blends and polymer additives for better workability and longevity.

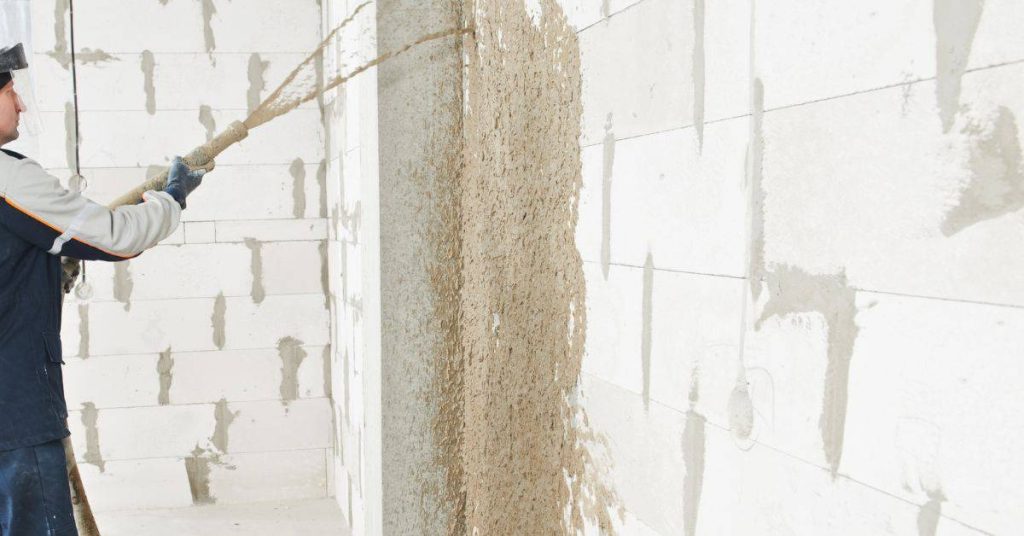

- Choose application method based on project: hand trowel for finish, spray for base coats.

- Ensure proper curing environment and joint detailing to prevent cracking; wear PPE.

Table of Contents

- Introduction

- Key takeaways

- Why Apply Stucco over CMU: Benefits, Limitations, and Decision Criteria

- CMU Substrate Assessment and Surface Preparation

- Bonding Agents and Primers: Selection and Application

- Scratch Keys, Lath, and Mechanical Fastening over CMU

- Stucco System Choices and Fiber Base Coat Advantages

- Curing, Environmental Controls, and Quality Assurance

- Crack Control, Reinforcement Strategies, and Joint Detailing

- Tools, Materials Checklist, Cost Factors, and Safety

- Conclusion

- FAQ

Why Apply Stucco over CMU: Benefits, Limitations, and Decision Criteria

Stucco over CMU can improve appearance, shed wind‑driven rain, and enhance fire performance while also offering opportunities for added durability and thermal improvement. Those gains depend on correct system choice—traditional cement stucco or polymer‑modified mixes—and on managing moisture and movement at the block face.

Limitations include risk of cracking, moisture management challenges, and the need for proper curing, maintenance, and substrate compatibility before installation. Before committing, check manufacturer instructions and local code implications, evaluate the CMU condition, required flashing/details, budget vs. life‑cycle value, and whether retrofit or new construction better meets your goals.

When to choose stucco over other claddings

Stucco is a versatile finish for CMU blocks, but it’s not always the best choice. Here are scenarios where stucco shines and when alternatives might be better.

Choose stucco: When you want a classic, timeless look. Stucco offers a wide range of colors and textures to match any architectural style. It also provides excellent weather protection and fire resistance.

Consider alternatives: If budget is tight, vinyl siding or fiber cement may be more affordable. For low-maintenance projects, consider EIFS (Exterior Insulation and Finish Systems) or brick veneer. Stucco requires proper curing and maintenance to last.

Typical failure modes to watch for

Stucco over CMU can fail if not installed correctly or maintained properly. Here are common problems and their causes:

Delamination: Peeling or separating of the stucco from the CMU substrate is often caused by inadequate surface preparation, improper mixing, or insufficient curing.

Cracking: Cracks can form due to settlement, thermal expansion/contraction, or inadequate reinforcement. Excessive cracking may lead to water intrusion and further damage.

Efflorescence: A white, powdery deposit on the stucco’s surface indicates moisture migration through the CMU blocks. This could be due to improper flashing, lack of damp-proofing, or high moisture content in the CMU itself.

CMU Substrate Assessment and Surface Preparation

A thorough substrate assessment identifies crumbling mortar, cracked blocks, efflorescence, trapped moisture, and any delaminating coatings that must be repaired or removed prior to stucco. Confirm moisture history and perform moisture, pH, and porosity tests where indicated to establish readiness for bonding and curing.

Cleaning should remove dust, oils, and salts using pressure washing, brushing, or approved cleaners without over‑eroding the block; document repairs such as repointing or unit replacement. Create a uniform surface profile for mechanical keying—record profile depth or roughness so you can match bonding agent and application thickness to the prepared CMU.

Cleaning, degreasing, and removing contaminants

The first step to a strong bond is a clean surface. Here’s how:

Use a stiff brush or broom to remove loose dirt and debris. For oil stains, use a degreaser or mineral spirits. Scrub with a stiff-bristle brush until the stain lifts.

Efflorescence – those white salt deposits – need to go too. Use muriatic acid diluted 1:4 with water. Apply, let it sit for 5-10 minutes, then scrub and rinse thoroughly. Safety first: wear gloves, goggles, and a long-sleeved shirt.

Pro tip: Don’t use high-pressure washers on CMU. They can erode the surface.

Repairing cracked or spalled CMU and mortar joints

Before you stucco, fix those cracks and crumbles:

For small cracks, use a concrete repair caulk. For larger ones, remove loose material, brush out dust, then fill with a patching compound. Let it cure.

Spalled blocks need replacing. Remove the damaged unit, clean the cavity, insert a new block, and repoint the joints. Use a Type N or Type S mortar for best results.

Pro tip: Don’t ignore those hairline cracks. They can grow into big problems under stucco.

Managing moisture, cavity details, and through-wall concerns

Moisture is your enemy here. Here’s how to keep it in check:

First, ensure you have a proper drainage plane behind the CMU. This could be a vapor barrier or a cavity filled with insulation.

Install flashing at all openings – windows, doors, etc. – to direct water out and away from the wall.

Through-wall concerns: If you’re applying stucco directly over CMU, ensure there’s no moisture trapped inside. Use a moisture meter to check. If it’s wet, wait until it dries or address the source of the moisture before proceeding.

Bonding Agents and Primers: Selection and Application

Chemical bonding (adhesive primers, polymer modifiers) relies on adhesion to the CMU surface, while mechanical bonding uses scratch keys or lath to develop a physical lock; each method has distinct failure modes and climate or substrate scenarios where it performs better. Evaluate CMU pore structure, contamination, and expected movement to choose between a chemical bond, mechanical keying, or a combined approach.

Select bonding agents and primers per the product data sheet and verify compatibility with your chosen stucco finish and any polymer modifiers. Prepare the surface—cleaning, controlled dampening, and profile verification—and perform simple pull or scratch tests where practical to confirm adhesion before full application.

Types of bonding agents and when to use them

Bonding agents help stucco stick to CMU blocks. Here are three types:

Cementitious primers: These are thin, cement-based coatings that seal the CMU surface and promote adhesion. Use them on clean, sound CMU with minimal suction.

Acrylic bonding agents: Acrylics provide better adhesion on low-suction or smooth surfaces like painted or sealed CMU. They’re also great for humid conditions as they resist mildew.

Polymer-modified mixes: These are cement-based with added polymers for enhanced flexibility and bond strength. Use them when expecting movement in the substrate, like expansive soils or temperature changes.

Proper application techniques and compatibility checks

Apply bonding agents right to ensure a strong bond:

1. Prepare the surface: Clean, dampen (but not wet), and roughen CMU as per earlier steps.

2. Mix and apply: Follow manufacturer’s instructions for mixing and application thickness. Use a brush or roller for primers, and trowel for polymer-modified mixes.

3. Check compatibility: Ensure the bonding agent is compatible with your chosen stucco mix and finish. Consult manufacturers’ data sheets for guidance.

Simple adhesion tests and common mistakes to avoid

Before applying stucco, test the bond strength to catch any issues early:

- Pull-off test: Apply a small piece of duct tape, press firmly, then pull off quickly. If it pulls off easily, re-prepare and retry.

- Scratch test: Scratch the surface with a screwdriver or coin. If the scratch is easy to remove, re-prepare.

- Avoid applying too thickly: Excess bonding agent can weaken the bond. Follow manufacturer’s guidelines for application thickness.

- Avoid applying in extreme temperatures: Bonding agents need moderate temperatures (50-90°F/10-32°C) to cure properly.

Regular checks and avoiding these common mistakes will give you a reliable bond before stucco application.

Scratch Keys, Lath, and Mechanical Fastening over CMU

Mechanical attachment methods serve different needs: scratch keys develop embedment in the mortar or base, lath distributes loads and ties reinforcement, and mechanical fasteners anchor systems where block geometry or condition requires. Decide on the method based on CMU soundness, exposure, and movement expectations; consult product guidance for compatible lath types and fastener schedules.

Prepare the CMU by removing laitance, aligning joints, and ensuring a clean, profiled surface before cutting scratch grooves or installing lath. When installing lath or fasteners, embed the lath properly, use corrosion‑resistant components, and maintain adequate coverage and fastening cadence to avoid point loads and reduce crack initiation.

Scratch Key Methods and When to Form Them

Formed mortar keys, mortar-filled reglets, and routed/formed keys are common scratch key methods. Each has its pros and cons.

Formed Mortar Keys: Cheap but labor-intensive. Grooves are cut into the CMU surface using a grooving tool or router. Fill with mortar for strong mechanical bond.

Mortar-filled Reglets: Pre-formed grooves in CMU blocks filled with mortar. Easy to install, good bond strength. Less labor than formed keys but more expensive.

Routed/formed Keys: Grooves cut using a router or other power tool. Allows for deeper, wider keys. Best for thick stucco coats and high wind loads. More time-consuming than other methods.

Installing Lath, Fasteners, and Corrosion Protection

Choose compatible lath types – metal or fiberglass. Attach using recommended patterns to ensure even distribution of load.

Metal Lath: Strong, durable. Use 16-gauge for CMU walls. Space fasteners 7/8″ apart along studs and 6″ on center horizontally. Embed in mortar for solid bond.

Fiberglass Lath: Lightweight, corrosion-resistant. Use 1/2″ or 3/4″ wide. Fasten every 6-8″ along studs and 4-6″ horizontally. Embed in mortar as with metal lath.

Corrosion Protection: For metal lath, use galvanized or stainless steel fasteners. Apply a corrosion-inhibiting primer to CMU surface before installing lath.

Scratch Coat Thickness, Timing, and Initial Scoring

The scratch coat is the first layer of stucco that bonds to the CMU wall. Its depth and timing are crucial for a strong bond.

Depth: Apply the scratch coat at least 1/4″ thick. For thicker coats, increase depth proportionally. This provides sufficient keying surface area.

Timing: Allow the scratch coat to set but not dry out completely before applying the next layer. Scratch when it reaches a leather-hard state – firm but can still be scored with a trowel.

Scoring: Use a straight edge and trowel to score the surface at 1/8″ to 1/4″ intervals. This creates additional keying points for better mechanical bond. Re-wet the surface before applying the next coat if it starts to dry out.

Stucco System Choices and Fiber Base Coat Advantages

One‑coat, two‑coat, and three‑coat stucco systems differ in layering, application sequence, and tolerance for substrate irregularity; choose a system that matches CMU condition, expected movement, and desired durability. Fiber‑reinforced base coats can improve early‑age strength, impact resistance, and shrinkage control, influencing whether a simpler one‑coat system suffices or a multi‑coat approach is safer.

Consider how fiber type and content affect workability and curing behavior and confirm compatibility with bonding agents and scratch keys per manufacturer information. For long‑term performance, follow recommended tooling and thickness targets—whether gun‑applied or hand‑troweled—and watch for common pitfalls such as over‑application or inadequate cure that negate the benefits of fiber base coats.

Fiber-reinforced vs conventional cementitious stucco

Alright, let’s talk about the two main types of stucco you’ll be working with. You’ve got your conventional cement-based stuff and then there’s the fiber-reinforced version.

Conventional Stucco: This is the old-school stuff. It’s just cement, sand, and water. It’s cheap, but it’s also prone to cracking. Why? Well, when it dries, it shrinks. And if your base isn’t properly compacted (check base compaction), you’re asking for trouble.

Fiber-reinforced Stucco: Now, this is where things get interesting. They add fibers to the mix – usually synthetic or natural ones like cellulose. These fibers change everything. Here’s how:

First off, they make your stucco tougher. Those fibers help hold everything together as it dries and shrinks. This means less cracking. Secondly, they reduce shrinkage. Less shrinkage means fewer cracks. It’s a win-win.

Sand gradation, aggregate selection, and their impact

The sand you use in your stucco mix affects workability, shrinkage, and long-term performance. Here’s what to consider:

Sand gradation: This is the size distribution of sand particles. For stucco, you want a well-graded sand with a good range of particle sizes. Check your sand’s gradation – it should have around 60% fines (particles smaller than #20 mesh) and 40% coarse sand (#20 to #4 mesh). This mix gives the best balance between workability and strength.

Aggregate selection: Aggregates like pebbles or shells can be added for texture. But be careful – using too much or the wrong type can cause problems. Check local codes, but typically, aggregates should make up no more than 20% of your mix by volume. And use clean, angular aggregates – round ones won’t stick as well and can lead to delamination.

Curing, Environmental Controls, and Quality Assurance

Effective curing preserves bond strength and reduces shrinkage cracks; select curing methods and durations that match your mix design and site weather, and follow product directions when using wet curing, misting, or coverings. Monitor temperature, humidity, wind, and evaporation risk so you can adjust protection and mist schedules during the critical early‑age period.

Implement QA practices: document mix batches and additives, keep field logs on curing actions, and perform simple field checks for consistency and surface set. Assign who records tests and sign‑offs, and include inspection steps for early cracking or delamination with clear corrective actions if issues appear.

Recommended curing practices and temperature/humidity checks

Curing is crucial for CMU-stucco applications. Follow manufacturers’ guidelines and local codes. Ideal temperatures range between 50°F to 90°F (10°C to 32°C). Relative humidity should be around 70% to 85%.

Wet-curing, mist-curing, or covering with burlap/plastic can help maintain these conditions. Duration depends on mix design and weather, typically 3-7 days.

Verify product data for specific curing needs. Too low or high temperatures, and insufficient moisture can weaken bond strength and increase cracking risk.

Environmental factors: wind, sun exposure, and humidity

Weather affects stucco curing. Wind speeds above 10 mph (16 km/h) can cause rapid drying, leading to cracking.

Sun exposure on hot days (>85°F/29°C) can also speed up drying. Protect surfaces with burlap or plastic during peak sun hours.

Monitor relative humidity. Low humidity (<40%) and high temperatures can lead to rapid evaporation, causing surface cracks. Keep surfaces moist using gaps, spray schedules, or curing compounds as needed.

Manufacturing and batch quality control to verify consistency

Consistent material performance is key. Check producer batch records for mix designs, additives, and supplier certificates.

Verify that aggregates meet required gradation and strength standards. Ensure cement meets ASTM C150 or equivalent standards.

Request field test results like slump/consistency checks, surface dry-time, and initial set to ensure batch consistency before application.

Crack Control, Reinforcement Strategies, and Joint Detailing

Minimize cracking by selecting reinforcement (mesh, lath, or rebar) appropriate to CMU size and expected movement and by placing reinforcement at recommended embedment depths and intervals. Include a jointing strategy—control and expansion joints located at predictable movement locations and transitions—to prevent random cracking across the stucco field.

Detail openings and corners with continuous reinforcement, closure beads, and properly sealed perimeters to reduce stress concentrations. Combine these detailing steps with correct scratch coats, compatible bond coats, and a moisture cure plan, and follow an inspection checklist to verify joint integrity and early‑age performance.

Placement and detailing of control and expansion joints

Control and expansion joints are crucial to manage cracking. They interrupt crack paths, allowing walls to move without stressing the stucco.

Control joints: Place them every 8-10 feet horizontally and vertically. Run them through corners and openings. Keep them 1/4″ wide.

Expansion joints: Install where walls meet, at transitions (interior/exterior), and around openings. Use backer rod and sealant for a tight fit.

Reinforcement options: meshes, fibers, and metal accessories

Choose reinforcement based on your CMU’s size and movement. Here are your options:

Wire lath: Good for small movements. Use 16-18 gauge, 4″ x 4″ mesh. Embed it 1/2″ into the scratch coat.

Fiberglass mesh: Ideal for larger CMUs and more movement. Use 3″ x 5″ or 4″ x 6″ mesh. Embed it 1/4″ to 1/2″.

Fibers: Add to your mix (0.5-1% by volume) for extra crack resistance.

Best practices for minimizing shrinkage cracks during application

Shrinkage can cause cracking. Here’s how to minimize it:

Mix proportion: Use a low-shrinkage cement and fine sand (max 1/8″ aggregate). Add fibers.

Application technique: Keep the stucco thickness consistent (<6″ max). Apply evenly, avoiding overworking or underworking.

Curing: Mist regularly for at least 72 hours. Avoid rapid drying to prevent excessive shrinkage.

Tools, Materials Checklist, Cost Factors, and Safety

Gather the essentials: bonding agents, base coat materials, mixers, trowels, scratch combs or keying tools, reinforcing mesh, floats, misters, and scaffolding or safe access equipment suited to the job. Match tool choices to the application method you plan—hand‑trowel or spray—and verify product directions for compatible accessories and PPE requirements.

Major cost drivers include material volumes, equipment rental, labor, and the condition‑dependent work for substrate repair or moisture mitigation; weigh DIY capability against the complexity of testing and detailing that might warrant a pro. Use appropriate PPE—eye protection, gloves, respirator for dust, and fall protection where required—and follow safe scaffold, ladder, and site‑control practices during work and curing periods.

Tools and materials checklist for stucco over CMU

Before you start, ensure you have all the necessary tools and materials to complete your job efficiently.

- Plaster mixer or drill with mixer attachment: Essential for mixing bonding agents, scratch coats, and cementitious stucco. Without it, mixing will be time-consuming and inefficient.

- Trowels (3-6 inch): For applying bonding agents, scratch/float coats, and finishing the final coat. Different sizes are needed for various tasks.

- Hawk: Holds mixed material while working with trowels to keep your hands clean.

- Stucco scratch comb or scratch keys: Creates grooves in the scratch coat to improve bonding with the next layer. Skipping this can lead to delamination.

- Reinforcing mesh (16-24 gauge): Adds strength and crack resistance to your stucco system. Without it, cracks may form due to shrinkage or movement.

- Mason’s line: Helps maintain a straight edge while applying materials and creates control joints for crack prevention.

- Plastic or metal floats (12-24 inch): Smooths and finishes the final stucco coat. Using the wrong float can result in an uneven finish.

- Water: Vital for mixing materials and proper curing. Insufficient water can cause premature cracking and poor adhesion.

- Curing compound and spray mister or misting set: Ensures proper hydration of the stucco, preventing early drying and cracking. Skipping this can lead to a weak, brittle finish.

Quick rule: Always check your tools and materials before starting work to avoid delays and ensure quality results.

Cost considerations: DIY vs professional installation

Understanding the cost factors can help you decide whether to tackle this project yourself or hire a pro.

- Material costs: Bonding agents, cement, sand, and mesh are essential. Buying in bulk can save money but may lead to waste if not used promptly.

- Equipment rental (mixer, scaffold, scaffold setup): Rental fees add to the overall cost. Consider long-term needs when deciding whether to buy or rent.

- Labor time: DIY projects save labor costs but may take longer due to lack of experience. Hiring a pro ensures faster completion but at a higher cost.

- Waste: Inefficient material usage and improper disposal can increase costs. Pros are trained to minimize waste.

- Substrate prep (moisture testing, surface cleaning): Proper substrate preparation is crucial for successful stucco application. Hiring a pro ensures this step is done correctly.

- Warranty considerations: Pros may offer warranties on their work, providing peace of mind but at an additional cost. DIY projects typically do not come with warranties.

- Complex detailing (arches, corners, ornaments): These areas require specialized skills and techniques. Hiring a pro ensures these details are executed correctly.

Quick rule: Weigh the costs of DIY vs hiring a pro based on your budget, available time, and skill level to make an informed decision.

Safety precautions, PPE, and environmental handling

Protecting yourself and the environment is crucial when working with cementitious materials.

- Eye/face protection: Wear safety glasses or goggles to protect from debris and chemical splashes. Without it, you risk eye injuries.

- Gloves: Protect your hands from cuts, abrasions, and chemical burns. Using the wrong gloves can lead to discomfort or inadequate protection.

- Respirator for dust and silica: Cementitious materials contain silica dust, which is harmful if inhaled. A respirator is essential for protecting your lungs.

- Hearing protection: Use earplugs or earmuffs when using power tools to prevent hearing damage from prolonged exposure to loud noises.

- Sturdy footwear: Wear work boots with good traction and toe protection. Without it, you risk slips, trips, and falls.

- Hard hat where required: Protect your head from falling objects in areas with overhead hazards. Not wearing a hard hat can result in serious head injuries.

- Fall-arrest or proper ladder/scaffold practices: Working at heights requires proper fall protection. Improper use of ladders or scaffolds can lead to falls and severe injuries.

- Site ventilation and perimeter safety: Ensure adequate ventilation when working with cementitious materials to minimize dust exposure. Maintain a safe perimeter to prevent unauthorized access to the work area.

Quick rule: Always prioritize safety by wearing appropriate PPE, following safe work practices, and maintaining a clean, organized workspace.

Conclusion

Getting a durable, good-looking stucco finish over CMU comes down to solid prep, proper bonding, and controlled curing. Do the prep right, and you prevent cracks, water intrusion, and costly fixes later.

First, verify the CMU is sound and dry, then select a compatible bonding agent, apply a proper scratch key, install lath or fastenings where required, and follow the fiber base coat and curing steps in the correct order. Check the work in small sections, keep moisture and temperature within limits, and document your process as you go so repairs are easy if needed.

Common mistakes to avoid include skipping surface assessment or keying steps, using the wrong primer or bond coat, and rushing curing or environmental controls. Practice Safety first by wearing eye and skin protection, working in good ventilation, and keeping kids and pets away. Test a small area first, follow the manufacturer’s directions, and don’t force cures or shortcuts that could trap moisture or produce weak bonds.

If the project involves uncertain structural conditions, persistent cracking, or complex detailing, don’t push ahead alone—call a pro. With careful steps, you’ll gain a durable, attractive finish you can be proud of and stand by for years to come.

FAQ

How should I quality-check bonding agents before laying stucco on CMU?

Follow the product label and manufacturer instructions exactly. Do a small test patch on CMU, check for good adhesion, and document the results before full-scale use.

Do specialized stucco products really improve performance, or is standard mix fine?

Specialized products can offer benefits like better adhesion or crack resistance, but read the data sheet and use what the manufacturer recommends for your job. Compare labeled claims to your conditions and follow their guidance for application.

What about sand blends and any additives—how to optimize them safely?

Use clean, well-graded sand per the product instructions and avoid dusty, clayey, or oversized material. If you mix in additives, only use those the manufacturer approves and test a small batch first to confirm workability and bonding.

What are proper wet-curing practices and ambient temperature limits for stucco over CMU?

Keep the surface moist for the period recommended by the product instructions and avoid rapid drying. Check the label for temperature ranges and note any restrictions near freezing or intense heat; follow those limits and guard against temperature swings during curing.