Introduction

Patch around electrical boxes in plaster by rebuilding the plaster edge so the cover plates sit tight and flush.

The guide walks you through assessing gaps, choosing patch materials, reproducing original edge profiles, and finishing for a seamless, code-compliant result.

You’ll learn practical steps, common pitfalls, and best practices to ensure a solid, professional-looking repair.

Key takeaways

- Inspect damage, plan repair before starting.

- Gather tools: trowel, joint compound, tape, sandpaper, safety gear.

- Protect floor and nearby areas, ensure good ventilation.

- Rebuild edge using joint compound, apply in thin layers.

- Achieve clean, square edge with careful troweling, sanding.

- Address old lath, crumbling plaster, wallpaper as needed.

- Prime, paint, install plates for finished look, long-term durability.

Table of Contents

- Introduction

- Key takeaways

- Assessing the Damage and Planning the Repair

- Tools and Materials Checklist

- Preparing the Work Area and Ensuring Safety

- Methods to Rebuild the Plaster Edge Around Boxes

- Techniques for Achieving a Clean, Square Edge

- Dealing with Special Situations (Old Lath, Crumbling Plaster, Wallpaper)

- Finishing: Priming, Painting, and Plate Installation

- Troubleshooting and Long-term Durability

- Material Specs, Standards, and Code Considerations

- Conclusion

- FAQ

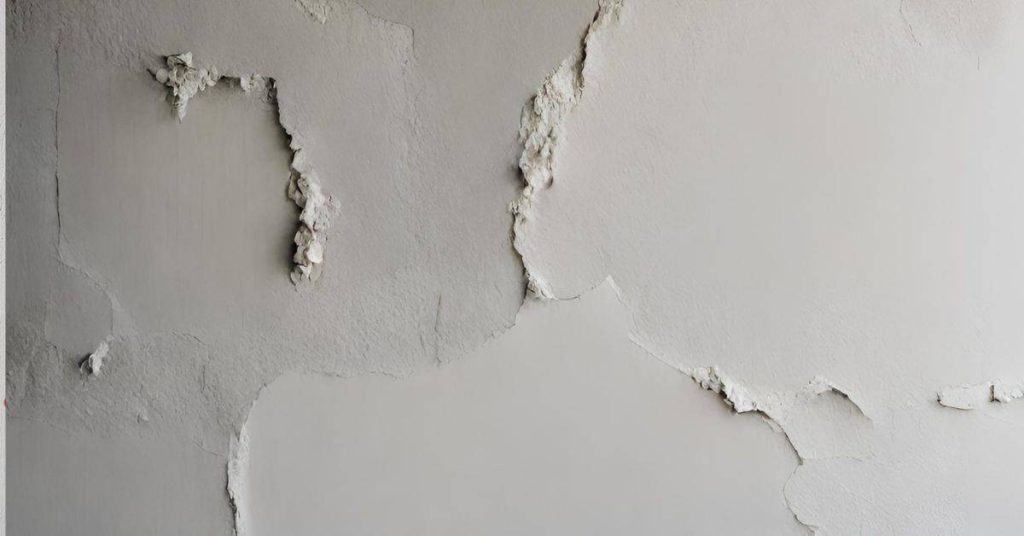

Assessing the Damage and Planning the Repair

To plan a repair, start by checking the plaster edge, the type of box, and the surrounding substrate. That tells you which repair method fits—patch, skim coat, or full replacement. Get a clear sense of what you’re dealing with before you cut or mix anything.

If you see damaged insulation, a corroded metal box, or any sign of live wiring, stop and call an electrician. Electrical work is not a DIY fix for safety reasons, and a bad job can start a fire or seriously injure someone. Understanding the material limits now keeps you from wasting time on the wrong repair later.

Before you begin, turn off power to the circuit at the service panel and verify the box is de-energized with a tester. If you’re ever unsure about wiring safety, don’t proceed—arrange for an electrician to inspect the box and the wiring. Clear notes about visible damage, insulation, and the condition of the lath or substrate will help you estimate repair scope and cost more accurately.

Red flags that warrant stopping and calling a professional include: buzzing or overheating outlets or boxes, exposed or crumbling lath, plaster that crumbles beyond a small edge, loose or shifting boxes, signs of moisture or previous water damage, and any wiring to the box that appears damaged or improperly grounded. If you encounter any of these conditions, escalate to a licensed electrician or qualified plasterer before continuing.

Identifying Box Type and Mounting (Metal, Plastic, Old-work)

Metal boxes are sturdy and usually mounted with screws into the wall studs. They provide a solid base for electrical connections but can be more challenging to work around when patching plaster.

Plastic boxes are lighter and often come with clips that attach to drywall or old plaster. These are easier to install and adjust, making them popular in DIY projects. However, they may not offer the same level of stability as metal boxes.

Old-work boxes are designed for retrofit installations without needing to cut into walls. They typically have wings that fold out to secure the box against existing surfaces. When patching around these, ensure the mounting is tight and secure before proceeding with plaster repair.

Measuring Gap Size and Plaster Thickness

To measure gaps around electrical boxes, use a small ruler or tape measure. Note the largest gap size to determine how much material you’ll need for patching.

The thickness of the plaster is also important. Use your fingers or a thin tool like a screwdriver to gauge this. Knowing both dimensions helps in deciding on the right repair approach and materials needed.

Accurate measurements ensure that the repaired area will be flush with the rest of the wall, making it easier for electrical plates to sit tight without gaps or protrusions.

Determining Repair Scope (Patch vs. Partial Replaster)

If the damage is limited to a small area around an electrical box, a focused edge rebuild might be sufficient. This involves cutting out only the damaged plaster and rebuilding just that section.

For larger areas with multiple issues or extensive cracking, consider a partial replastering approach. This means working on a broader patch of wall to ensure uniformity in texture and finish.

In cases where the damage is widespread or there are significant structural concerns, it may be best to consult an electrician for advice before proceeding. They can assess if a full skim coat is necessary to restore the wall’s integrity and appearance.

Tools and Materials Checklist

This section gives the must-have tools and materials for common edge-rebuild methods, plus safety gear. Start with the basics: measuring and cutting tools, fasteners, adhesives, and the right protective gear. If budget is tight, choose versatile tools and buy safety gear first.

Having a focused toolbox keeps your project moving and prevents trips back to the store. It helps you choose the right method, price, and approach for single repairs or limited budgets.

Essential Tools (Screwdrivers, Utility Knife, Oscillating Tool, Trowel)

You’ll need a few key tools to get the job done right. Each tool has its specific role in cutting, scraping, and applying plaster or compound.

- Screwdriver set for removing old screws and installing new ones

- Utility knife for scoring lines and trimming excess material

- Oscillating tool with various blades to cut out damaged areas precisely

- Trowel in different sizes for applying plaster or compound smoothly

- Cordless drill with bits for drilling holes if needed

- Hammer for driving nails or tapping boxes into place

- Measuring tape to ensure accurate measurements and cuts

Stop working when you notice any movement in the wall, as this indicates instability that needs addressing.

Materials by Method (Plaster, Setting-type Compound, Thinset, Backer)

The materials you choose depend on the extent of damage and your repair method. Non-drying compounds work well for small gaps, while setting-type compounds are better for larger repairs.

- Plaster powder to rebuild plaster edges

- Setting-type compound for filling large gaps quickly

- Thinset mortar as an adhesive when securing backer material

- Backer board or mesh tape to reinforce weak areas

- Sandpaper for smoothing rough surfaces before painting

- Painters’ putty for minor touch-ups after plastering

- Vacuum cleaner with attachments to clean up debris

If you notice any movement in the wall while working, stop immediately and address the underlying issue.

Fasteners, Shims, and Box Extenders

Using the right fasteners and shims can help secure electrical boxes firmly in place. Metal or plastic shims are used to fill gaps and ensure a tight fit.

- Metal screws for securing metal boxes into studs

- Plastic anchors for mounting plastic boxes in drywall

- Box extenders to move electrical boxes further out from the wall if needed

- Screws and nails of various lengths for securing backer material

- Plastic clips to hold wires in place while working

If you notice any movement or instability, stop immediately and reinforce the area before proceeding.

Preparing the Work Area and Ensuring Safety

Before you touch a plaster repair, shut the power off at the breaker. Test for live circuits with a tester and lock out if you can. Protect surrounding finishes and set up dust control to keep the room clean.

This isn’t optional gear, it’s basic safety. A spark or blown fuse can ruin the whole project or cause a shock. Following these steps keeps you and your family safe and makes the repair go smoother.

Shutting Off Power and Testing

Before you start any work around electrical boxes, turn off the power at your circuit breaker or fuse box. Double-check each switch to ensure it controls the correct circuits.

Use a non-contact voltage tester to verify that there’s no electricity in the wires near the box. If you’re unsure about which breaker to flip, test all of them until you find the right one.

If your tester shows any signs of live current, stop and call an electrician. Safety first, always.

Containing Dust and Protecting Finishes

Cover the area around your work with drop cloths or plastic sheets to catch plaster dust and debris. Use painter’s tape to seal edges tightly.

A HEPA vacuum is ideal for cleaning up drywall dust, but if you don’t have one, a regular vacuum with a damp cloth can do in a pinch. Clean as you go to keep the area manageable.

Wear gloves and safety glasses when cutting or sanding plaster to protect your hands and eyes from sharp edges and flying particles.

Personal Protective Equipment

Before you begin, make sure you have the right gear on hand. Safety comes first in any DIY project.

- Safety glasses: Protect your eyes from flying debris and dust while working with plaster.

- N95 respirator or mask: Keep dust out of your lungs when sanding or cutting plaster.

- Gloves: Wear them to shield your hands from sharp edges and chemicals used in repairs.

- Hearing protection: Use earplugs or earmuffs if you’re using noisy tools like an oscillating tool.

- Coveralls or old clothes: Keep work clothes separate from regular wear to avoid tracking dust home.

For items that are expensive, consider renting them for the day rather than buying. This way, you only spend on what you need without cluttering your tool collection.

Methods to Rebuild the Plaster Edge Around Boxes

There are three proven ways to rebuild the plaster edge around boxes. Use box extenders, a feathering patch with setting compound, or a backer plus a floating coat, depending on the gap and the plaster condition.

Box extenders work fast for larger gaps or when the plaster edge is rough and you want a clean, flush finish. For small to medium gaps and solid plaster, a feathering patch with setting compound is the simplest repair. If the plaster is loose or you have a big void, use a backer and a floating coat to tie it in before the final skim.

Using Box Extenders and Adjustable Rings

When the gap around an electrical box is small, using extenders or adjustable rings can be a quick fix to bring the box flush with the wall surface. Choose an extender that fits snugly over your existing box without damaging it.

To install, start by turning off power at the breaker and removing the old mounting clips. Inspect the box for cracks or loose screws and remove them as needed. Clean the box flange and surrounding plaster edge with a stiff brush to remove dust. Dry-fit the extender to verify a tight fit, then fasten it securely against the back of the drywall or plaster using the screws provided with the extender kit. If you’re bridging a gap up to about 1 inch, use a compatible extender or a shallow adjustable ring. After installation, tighten all screws, re-check plumb and level, and gently test the box with a light push to ensure there’s no wobble. This method works best for gaps up to about an inch wide but check manufacturer recommendations. Allow any patch material around the box to cure per the extender kit instructions before final trim or plate mounting.

Backer Support with Thin Plywood or Metal Lath

To rebuild a damaged plaster edge, adding backer support behind the wall is crucial. Use thin strips of plywood or metal lath to create a solid base for new material. Cut your backing strip slightly wider than the gap and long enough to overlap undamaged areas.

Secure the backing firmly against the existing structure using screws or nails. This provides stability and ensures that any new plaster will adhere well, making it easier to mount electrical plates tightly afterward. Metal lath is ideal for larger gaps or where extra strength is needed. Before applying backing, remove dust, loose plaster, and any fasteners near the area. Use a suction cup or helper to hold backer pieces in place while you start fastening. Space screws or nails every 4 to 6 inches along the backing to maximize bite. If stabilizing a loose edge, you may need to score or key the plaster back edge to improve adhesion. After the backer is secure, wipe down the area and proceed with a feathering or skim coat as needed, allowing for cure time between steps as recommended by setting or plaster product manufacturers.

Feathering with Setting-type Plaster or Polymer Compound

To rebuild a plaster edge around an electrical box, feathering involves applying thin layers of setting compound to gradually build up the thickness. Start by mixing your compound according to package instructions for a smooth consistency.

Apply the first layer thinly and evenly over the damaged area, feathering it out smoothly into undamaged sections. Allow this layer to set slightly before adding another coat if more thickness is needed. Repeat until you achieve the desired edge height, ensuring each layer blends seamlessly with existing plaster.

Practical sequencing and tips: for a typical edge rebuild, plan on 2 to 4 thin coats rather than one thick layer. For setting-type plasters, expect initial tack in 15 to 30 minutes, with final set within 1 to 2 hours depending on product and ambient temperature. Between coats, lightly scuff the surface with a damp sponge or a fine-grit sanding block after the first coat has firmed up but before it fully hardens, to improve bonding of subsequent layers. Do not apply the final skim until the feathered edge is flush with the surrounding plaster and free of high spots. After finishing cuts, wipe away excess material and check the box fit—tighten screws and mounting hardware once the plaster has cured to the touch. If you’re integrating a backer with a feathering patch, you may alternate between backer consolidation and feather layers to avoid cracks, then follow with a final skim coat for a smooth surface ready for plate installation.

Techniques for Achieving a Clean, Square Edge

To get a true 90-degree edge, start with a metal corner bead, then tape it solidly and screed smooth. When done right, the bead anchors the corner, the tape seals the joint, and the plaster stays flush. That setup makes the cover plate sit flat with no gaps.

Skimp on any step and you’ll see gaps, wobble, or a crooked edge that bites you later. This matters on sight lines and trim, and it saves headaches when you install outlets or switches. Do it right: clean beads, tight tape, and a level pass every time.

Installing Metal or Plastic Beads for Crisp Corners

To get those sharp edges, start by cutting your metal or plastic corner beads to fit snugly around the electrical box. Use a screwdriver to secure them in place with small nails or staples every few inches.

Once the bead is firmly attached, apply plaster or setting compound over it, making sure to embed the bead fully into the material for durability. This will give you a straight edge that won’t crack or chip easily.

After embedding the beads, smooth out any excess material with your trowel to ensure a clean finish. Let it dry completely before moving on to the next steps.

Screeding and Striking a Consistent Edge

To achieve a level edge, use a straightedge or strike-off tool to remove excess plaster around your electrical box. This helps ensure the new plaster aligns perfectly with the existing wall.

Hold the straightedge firmly against the surrounding plaster while you scrape away any high spots with your trowel. Aim for a smooth transition between old and new work.

This step is crucial for maintaining a clean, professional look. It also helps prevent future cracks or unevenness in the wall surface.

Sanding, Shaping, and Preserving Box Clearance

After your plaster has dried, carefully sand down any rough edges to smooth them out. Use a fine-grit sandpaper or sanding block for best results.

Avoid over-sanding around the electrical box area as this can compromise the necessary clearance needed for proper installation of cover plates and switches.

Keep an eye on the depth of your plaster layer near the box to ensure it doesn’t interfere with the mounting screws. A little extra care here goes a long way in achieving a neat, professional finish.

Dealing with Special Situations (Old Lath, Crumbling Plaster, Wallpaper)

Old lath or plaster crumbles, and plaster may be missing around a box. You need careful patching, backing, and proper prep before anything else.

This matters on a DIY jobsite because sloppy prep leads to cracked walls, loose boxes, and extra rework. Take a little time to clean, score, and seal surfaces; skip that and you’ll pay later in cracks.

Repairing Around Keys and Lath Strips

If your plaster has wooden lath strips with keys that are loose, start by securing them back in place. Use small nails or staples to hold the keys tight against the lath.

For areas where keys are missing entirely, bridge the gaps using thin metal mesh or fiberglass tape before applying new plaster. This helps create a stable base for your patch.

If you find sections of lath that have come loose from the wall, reattach them firmly with construction adhesive and nails to ensure they stay in place during repair work.

Bonding to Crumbling or Friable Plaster

Crumbling plaster can be challenging, but you can stabilize it with consolidants before patching. Apply a consolidant according to the manufacturer’s instructions to strengthen the existing material.

If consolidation isn’t enough, consider removing the loose plaster down to solid substrate and then applying new base layers like gypsum board or metal lath for better adhesion.

For small areas of friable plaster, you might be able to patch directly after cleaning off any dust and debris. Feathering your repair will help it blend in with the existing surface.

Working Where Wallpaper or Tile Meets the Box

When repairing around electrical boxes where wallpaper is present, carefully trim away any excess paper from around the box. Use a utility knife to cut neatly along the edges.

If you’re working with tile, remove small sections of grout near the box to create space for your repair work without damaging surrounding tiles.

Integrate your plaster rebuild so it matches seamlessly with adjacent finishes. Feathering the edge will help achieve a smooth transition and ensure that switch plates sit flush against both materials.

Finishing: Priming, Painting, and Plate Installation

Finish prep is what makes the cover sit flush for good. Prime first to seal the surface and prevent suction when the plate goes on. Then paint to blend edges and install the plate so, once cured, the cover sits tight and flush.

Skipping cure times or primer leads to gaps, peel, and misalignment. The payoff is a smooth, durable finish that lasts and stays flush with little fuss later. Take the time to cure, prime, and test fit before mounting the final plate.

Curing and Moisture Considerations for Compounds

After applying setting-type plaster or polymer compound around electrical boxes, it’s crucial to let the material cure properly. This usually takes about 24 hours but can vary depending on humidity levels, temperature, and the compound used. In cooler or humid conditions, expect longer cure times and plan accordingly.

To avoid rewetting the repair area, which could soften and damage your work, keep the site dry for at least a day after application. If you’re working in a humid environment, extend this period to ensure full curing. Protect the area from moisture, accidental splashes, and steam (for example, from bathrooms) during cure. Ensure the room temperature stays within a usable range (roughly 60–85°F / 15–29°C) as the compound cures.

Safety note: power should be de-energized at the circuit breaker and a temporary cover plate should be used while any patch is setting to prevent debris or contact with live conductors.

Priming and Matching Texture/paint

Selecting the right primer is key for ensuring your repair blends seamlessly with the existing surface. Use a high-quality bonding primer that matches the type of material you’re working on, whether it’s plaster or drywall. For plaster repairs, a shellac- or shellac-leaning bonding primer can help seal porosity and improve paint adhesion; for drywall, a good latex-based primer works well. Apply a thin, even coat and allow it to dry according to the primer’s instructions before painting.

To match the texture, replicate the original finish carefully. If the wall has a stippled look, use a spray can or stipple tool to mimic this effect after priming. For smoother surfaces, feather-sand your repair area lightly and remove dust before painting. If you see evidence of old paint shedding or compound dust, wipe or vacuum the area before priming to improve adhesion.

Choose interior, low-odor paints suitable for plaster or drywall and finish with a matte or eggshell sheen that matches surrounding areas. When painting, cut in around the plate area first, then roll the field to minimize lap marks. Allow each coat to cure fully before applying the next.

Final Plate Fit, Torque, and Anti-rotation Tips

To ensure the electrical plate sits tight without warping over time, use screws with a torque that’s just enough to hold but not too tight. A typical starting point is around 15 inch-pounds of torque; if you can, verify with the plate manufacturer’s recommendations. Use a torque driver or a properly sized screwdriver with a quality bit to avoid slippage and damage to the screw heads or plate.

For added security against rotation, consider using nylon inserts or washers under the screw heads. This helps prevent splitting and keeps the plate flush even as it ages. If the box or mounting surface is uneven, place a small composite shim behind the plate where needed to achieve a flat, flush fit. Recheck alignment after final tightening and test the plate by gently wiggling to confirm it remains flush and square.

Troubleshooting and Long-term Durability

The big idea here is to keep the plate tight and solid so failures don’t creep in. Plates loosen, crack, and hollow out when you ignore maintenance, so inspect and tighten as part of a regular plan. Do not skip the checks; small looseness today becomes a big problem tomorrow.

Fixing a Loose Plate After Initial Repair

If your electrical plate feels loose after patching around the box, start by checking if you can tighten it up with shims or adding some backing behind the wall. Sometimes, simply repositioning the box extender can help secure the plate again.

When these methods don’t work, consider removing the old repair and starting fresh. Focus on ensuring a solid bond between new plaster and existing walls to prevent future loosening. Use a strong adhesive or compound that matches your wall material for best results.

Preventing Future Cracking and Settlement

To keep repairs from cracking over time, install control joints at regular intervals. These joints allow the plaster to expand and contract without breaking. Place them about every 4 feet or so depending on your specific conditions.

Also, ensure you layer materials properly during repair work. Start with a base coat that adheres well to old surfaces, then add a middle coat for strength, followed by a finishing coat for smoothness. This layered approach helps distribute stress evenly and reduces the chance of cracking.

Avoid excessive vibration near repairs as it can cause settlement issues. Be mindful when working around plumbing or other areas prone to vibrations. If you notice any signs of movement during repair work, address them immediately by reinforcing the area with additional backing material.

When to Replace the Box or Call a Pro

If your electrical box shows significant corrosion, it’s time to replace it. Corrosion weakens metal boxes and can lead to safety issues over time.

A severely misaligned box is another clear sign you need help from an electrician. Misalignment can cause the plate to sit crookedly or not fit properly, which looks unsightly and may be a fire hazard.

Lastly, if there’s any structural movement around the electrical box, such as cracks in the wall or shifting of nearby fixtures, it’s best to consult a professional electrician. Structural issues can compromise safety and require specialized knowledge to fix correctly.

Material Specs, Standards, and Code Considerations

Electrical work must meet clearance rules, box depth, and material standards to stay safe and code compliant. Use the right box depth for the device and the right gauge and type of cable. Always verify the local code for any rule changes.

Falling out of spec can cause shorts, fires, or nuisance tripping. Knowing the standards saves rework and headaches on a jobsite and helps you pass inspection. Always verify with the local building department or the authority having jurisdiction before you cut or install.

Required Box Depth and Cover Plate Clearance

The National Electrical Code (NEC) sets minimum box depth requirements to ensure that electrical boxes are safely recessed into walls or ceilings. For standard residential work, the box should extend at least 1/4 inch behind the surface of the wall or ceiling.

When patching around an electrical box in plaster, you need to account for the thickness of your finish material—typically about 3/8 inch for a skim coat and up to 1/2 inch if you’re rebuilding a larger area. This ensures that the cover plate sits flush with the wall once installed.

Always check local building codes before starting any electrical work, as they may have specific requirements or exceptions based on your location’s standards.

Fire-stopping, Grounding, and Junction Rules

When repairing around an electrical box in a wall cavity, it’s important to maintain fire-stopping integrity. This means using appropriate materials like fire caulk or foam to seal gaps where necessary.

Grounding continuity is another critical aspect. Ensure that grounding connections are secure and continuous from the box through any junction boxes you install during repairs. Check local codes for specific requirements on grounding methods.

If your repair involves adding a new junction box, make sure it’s accessible and complies with NEC standards regarding size and location to facilitate future maintenance or upgrades.

Choosing Materials That Meet Standards (UL, ASTM)

Selecting the right materials is crucial for both safety and durability. Look for products certified by organizations like UL (Underwriters Laboratories) or ASTM International.

- Plaster Compound: Use a compound that meets UL standards for fire resistance and structural integrity.

- Metallic Mesh: Choose mesh with UL ratings if it’s part of your repair, ensuring it supports the weight and stress of plaster.

- Wood Backer Board: Pick boards certified by ASTM to ensure they’re resistant to moisture and won’t warp over time.

- Masonry Anchors: Select anchors that meet UL standards for load-bearing capacity in concrete or masonry walls.

- Plastic Boxes: Use boxes with UL ratings, ensuring they can handle the electrical load safely.

Avoid using warped or weak materials as they may compromise your repair’s stability and longevity.

Conclusion

Rebuilding the plaster edge around boxes and seating the plates tight is about making the repair durable and safe, not quick patchwork. If you lock in the edge shape, test fit, and finish with proper priming and paint, you’ll avoid future cracks and misalignment that jack up costs.

First, assess the work area, gather the exact tools and materials you planned, then work in a logical sequence: confirm the frame or lath is sound, rebuild the edge to square tolerances, test fit the plate, then prime, paint, and install the plate without forcing it. Always power down and test circuits, wear eye protection, and keep a clear work zone so you don’t nick wiring or disturb surrounding plaster.

Common mistakes to avoid include rushing the edge rebuild without a dry fit, overworking plaster in a thin area and causing crumbling, and skipping the primer before plate installation. Safety rules to follow are simple: shut off power at the breaker, verify no live wiring before cutting or chipping, and protect yourself with gloves and eye protection when chiseling or mixing patch materials. If the plaster is crumbling, or the wall has old lath behind a brittle face, don’t push beyond your comfort zone—these need a careful approach or a pro.

If you’re unsure about old wiring, severe damage, or persistent misalignment after a test fit, it makes sense to call a professional. With careful planning and deliberate steps, you’ll finish with a clean, square edge, a sturdy plate, and long-term durability. Stay patient, stay safe, and you’ll get a solid, professional-looking result.

FAQ

What causes the plates to become loose around electrical boxes?

Cracks and holes form due to nails, screws, or improper tapping into walls during past renovations. Over time, this weakens the plaster, making it crumble when installing new devices.

How can I prevent breaking more plaster while repairs?

Gently cut along the outside edge of the box using a utility knife to score the plaster and create a clean line for your patch. This stops further cracking before you start working on it.

Should I use joint compound or spackle for this repair?

For plaster walls, use a setting-type joint compound, not spackle. Spackle is too weak and dries too quickly for proper adhesion in this situation.

How do I ensure the new plate sits tight after patching?

Sand the patched area smooth, apply primer to seal it, then let both dry fully before installing any devices or faceplates. This prevents future issues and ensures a strong bond with the new installation.