Introduction

Place and properly support rebar chairs so the steel stays off the ground during the concrete pour.

You’ll learn practical placement techniques, how to choose the right chair heights, and how to check alignment so the concrete cures with the correct reinforcing position.

The guide walks through common mistakes, quick rules of thumb, and safe practices for consistent, durable results.

Key takeaways

- Keep rebar at least 2 inches above ground for sheath protection.

- Choose chairs rated for anticipated load and concrete pour height.

- Bond chairs securely with concrete-compatible ties to prevent displacement during vibration.

- Plan staggered chair rows to maintain uniform rebar cover around edges.

- Verify chair height aligns rebar within flange clearance and formwork.

- Inspect before pour: confirm all chairs are level, stable, and clean.

Table of Contents

- Introduction

- Key takeaways

- Why keeping rebar off the ground matters

- Types of rebar chairs, supports, and alternatives

- Material specs and standards explained

- Planning placement: spacing, layout, and sequencing

- Step-by-step installation process

- Tools and materials checklist

- Visual checkpoints and inspection guide

- Common mistakes and how to avoid them

- Maintenance, removal, and post-pour considerations

- Conclusion

- FAQ

Why keeping rebar off the ground matters

Keeping rebar off the ground is essential for strength and durability. When rebar rests on soil or forms it can corrode and trap moisture, reducing its ability to reinforce the concrete and create proper coverage.

Raising rebar above the ground ensures proper concrete cover and easier inspection during pours. For DIY and jobsite work, using chairs or spacers saves time, prevents corrosion, and helps the slab perform as intended.

Corrosion and contamination risks

When rebar sits on the ground it picks up moisture, salts and organic debris. Those things speed up rust. Rust reduces the steel section and eats at the ribs that grip concrete.

Contaminants on the bar also break the bond between steel and concrete. You lose load transfer and stir up hot spots for cracking. Keep in mind the earlier notes about clearance — ground contact makes those problems much worse.

Practical rule: keep bars off dirt and away from wet spots to limit corrosion and preserve bond strength.

Impact on concrete cover and structural integrity

Proper cover is what keeps the rebar protected and the slab behaving as designed. If bars touch the ground they often end up too low in the pour. That reduces cover and compromises durability.

Less cover means lower load capacity, poorer crack control and potential code failures. You may pass a visual but fail an inspector or see premature cracking under service loads.

Do the job right: use chairs, spacers or blocks so bars stay at the specified height and the structure performs as intended.

Types of rebar chairs, supports, and alternatives

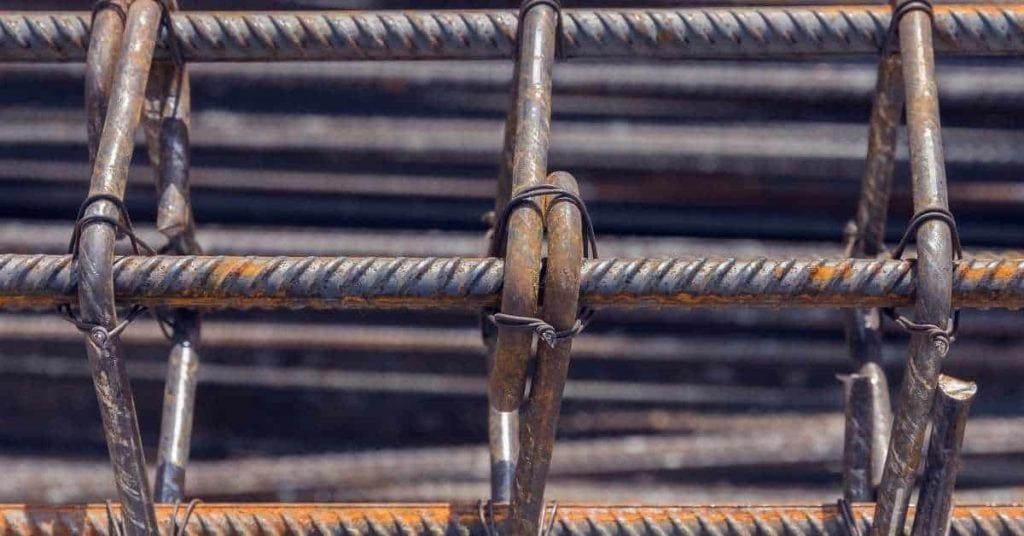

Rebar chairs and supports come in several common types—plastic chairs, steel chairs, concrete blocks, wire supports, and saddle chairs. Each type is designed to hold rebar at the correct height and spacing so the concrete covers stay consistent.

Proper supports keep rebar in the correct position through the pour, reducing movement and concrete voids. For DIY projects, choose plastic or steel chairs for ease, blocks for uneven ground, wire supports for light grids, and saddle chairs for curved bars.

Plastic and polypropylene chairs

These are the go-to for light to medium reinforcement. They resist corrosion, won’t stain concrete, and are cheap enough to throw away after the job. For slabs and non-structural pours they work well.

They clip onto rebar quickly and keep cover consistent. Use them where loads are moderate and longevity of the support isn’t a concern. For heavy cages or high load points, switch to stronger supports.

Tip: they’re easy to transport and set, so they save time on small pours and DIY jobs.

Prefabricated steel chairs and wire supports

Steel chairs and wire supports carry heavier loads and keep big reinforcement cages in place. Use them under columns, beams, and heavy slabs where chair collapse would be dangerous. They’re common on commercial jobs for that reason.

Steel can rust and cause staining or long-term corrosion if left exposed. Protect exposed steel with plastic caps, galvanizing, or place them where the concrete cover is sufficient. Follow specs for chair spacing and load limits.

Tip: prefer prefabricated steel when load and stability matter; use wire ties and check alignment before the pour.

Concrete blocks, spacers, and DIY alternatives

Concrete blocks and cast spacers are simple and strong. You can cast small concrete pads on site or use commercial spacers for heavy reinforcement. They’re acceptable when they meet the required cover and strength per the job specs or building code.

Keep them clean and solid. Avoid loose or crumbling pieces that can shift during the pour. For DIY alternatives like mortar dabs or stacked bricks, only use them on non-critical work and ensure they don’t violate the engineer’s requirements.

Tip: document any on-site fabrications and get approval when working on structural elements.

Material specs and standards explained

This section explains the main standards that govern concrete material specs, such as strength, cover, and mix requirements. It highlights relevant codes from ACI, ASTM, and local building codes, and what they mean for your project. You’ll learn the minimum cover for typical applications.

Knowing these standards helps you choose the right mix and protect durability on site. Following the rules reduces risk of cracks, corrosion, and failed inspections, saving time and rework. Use these guidelines to plan proper reinforcement, curing, and safety.

Minimum concrete cover requirements

Keep the right cover to protect rebar from corrosion and to meet code. For slabs-on-grade a common minimum is 50 mm (2 in) to the top of the footing or slab surface, but that can drop to 20–40 mm for interior slabs where exposure is low.

Beams and columns normally need more—typical covers are 40–75 mm (1½–3 in) depending on bar size and exposure. In marine, coastal, or severe exposure conditions increase cover as required by your local code or the project specs.

If you’re unsure, follow the controlling standard (ACI/ASTM/local code) shown on the drawings and use the larger specified cover when in doubt. Measure from the concrete surface to the outermost face of the reinforcing bar or stirrup, not to the center of the bar.

Design-check tip: cross-check the minimum cover with the project drawings and the rebar size chart in the applicable code. If the drawings specify a larger cover for durability or corrosion protection, follow that value even if it exceeds the generic minimum. For critical locations (exposure, de-icing salts, or marine environments) require engineer-approved tolerances and field verification before pours.

Chair load ratings and compatibility with rebar sizes

Pick chairs rated to carry the weight they’ll see on site. For light work a small plastic chair can handle rebar and a few workers. For heavy grids, wire chairs or concrete blocks with higher load ratings are needed. Check the manufacturer rating stamped or on the tag.

Match seat dimensions to the bar diameter so the bar sits securely and won’t roll when you pour. Use higher-capacity chairs under intersections or where construction traffic concentrates. Never use undersized chairs just to save money—bars can shift and lower cover during placement.

Also confirm chemical compatibility; some plastic chairs are fine, others can be affected by curing agents. When in doubt, use approved chairs noted on the spec or ask the engineer for a substitute that matches load and spacing requirements.

Design-check tip: require engineer-approved chair types and spacing, and document the rating (load, size, and model). Verify during pre-pour inspection that the chosen chairs align with the drawings, rebar layout, and any temporary bracing. For large or heavily loaded grids, plan extra chairs at intersections and use non-shifting supports to maintain cover during concrete placement.

Planning placement: spacing, layout, and sequencing

Plan chair spacing and layout to match the rebar grid and slab thickness. Consider how construction traffic will move and the order of concrete pours. Getting these details right helps ensure a stable, level slab.

Good planning minimizes wobble and misalignment, keeping chairs in place during pours. It also helps distribute load evenly as concrete is poured and cured, reducing cracking risk. With a clear spacing plan, a DIY crew can work faster, safer, and with better results.

Spacing rules for different rebar grids

Match chair spacing to the bar size and load. For light-duty slabs with #3 and #4 bars you can run chairs at 24″ to 36″ centers; for #5 and #6 drop spacing to 18″ to 24″; for #7 and #8 use 12″ to 18″. Wider grids let chairs travel more load between supports and increase the risk of deflection.

Keep chairs closer where construction traffic or concentrated loads occur. If the rebar grid is wide, put a row of chairs under each bar intersection and additional rows mid-span to control bounce. Use stiffer chairs or double-up where spans exceed the common spacing to prevent sagging during the pour.

Staggering and overlap strategies

Don’t line chairs up in long straight lines that create a shear plane. Stagger rows so supports sit under different intersections and transfer load across the slab. Place chairs under bar intersections and shift adjacent rows half a bay to avoid a continuous weak line.

At laps and splices give extra support: add a chair directly under the lap and one on each side within 12″ to 18″. When using wire ties or supports at intersections, make sure the chairs sit solidly on the slab form or subgrade so the lap zone doesn’t sink during the pour. Reinforce lap zones where heavy traffic or concrete drop chutes are planned.

Step-by-step installation process

This section outlines a clear, step-by-step installation process from site prep through final checks just before pouring concrete. Follow the sequence to prepare the base, set forms, place reinforcement, and verify levels and moisture conditions.

Knowing the order helps prevent common mistakes and keeps the project on track for a solid pour. Proper preparation reduces rework, promotes uniform thickness, and supports an efficient, safer jobsite.

Step-by-Step Installation Process

This sequence gets the slab reinforcement ready from clean site to ready-for-pour. Follow each step in order and check as you go.

- Clear and mark the area. Remove debris and vegetation so the base sits flat; a clean footprint prevents surprises when digging. Check your lines with stakes and a string; they should match your plan.

- Excavate and compact the subgrade. Dig to the required depth and compact in layers so the base won’t settle later. Use a plate compactor and test with a straightedge; no soft spots should remain.

- Install subbase and vapor barrier. Lay crushed stone and a polyethylene sheet if required to control moisture and support chairs. Make sure the stone is level and the barrier overlaps at seams.

- Place chairs and position rebar. Set chairs at the specified spacing and tie rebar to maintain cover; correct positioning keeps steel where it belongs in the slab. Give each run a light tug—ties should hold and chairs should stay vertical.

- Check reinforcement alignment and supports. Measure cover at multiple points and confirm reinforcement layout matches drawings. Correct any misalignment now; adjustments become hard once the pour starts.

- Coordinate pour window and vibration management. Establish the pour start time with the crew, and confirm the expected pour duration based on slab size and mix. Communicate pump/chute locations and ensure equipment will not disturb or overturn chairs. Use low, steady vibration and avoid aggressive hammering near the reinforcement; if possible, place rebar and chairs well before pumping begins so they aren’t disturbed by early operations. During the pour, monitor chair and rebar stability; if movement is observed, pause the pour and recheck alignment before continuing.

- Secure edges and formwork. Install forms and bracing so they hold line and elevation under pour pressure. Tap test the forms and walk them to ensure no movement.

- Pre-pour safety and access setup. Plan pump and chute locations, set up walkways, and keep wheelbarrow routes clear to avoid trampling chairs. Confirm everyone knows their role and where the concrete will enter.

- Final sweep and documentation. Remove loose debris, take photos of layout for records, and mark any items that need protection during the pour. A final photo set saves arguments if an inspector asks later.

- Call for inspection or proceed to pour. If a structural inspector is required, have them sign off; if not, begin the pour once all checks are green. If anything looks off or unstable, stop and get a pro to evaluate.

Site preparation and leveling

Start by removing organic material, roots, and topsoil until you reach firm material. Loose or soft soil will allow the slab to settle, so work until the ground feels solid underfoot.

Build a uniform subbase with compacted crushed stone in 2–4 inch lifts. Compact each lift with a plate compactor until the surface shows no bounce under load and a straightedge rides true.

Lay a vapor barrier if required by the plan or local code. Overlap seams and tape them; the barrier keeps moisture from moving up into the slab and protects the chairs and rebar during work.

Positioning and securing chairs to rebar

Place chairs at the spacing called out on the drawings and set their tops to the correct height for concrete cover. Use a measuring stick or gauge to spot-check heights across the grid so the reinforcement stays at design elevation.

Attach chairs to rebar with tie wire or manufacturer clips; wrap and twist ties snugly so chairs won’t spin or walk during concrete placement. For lightweight chairs, use two ties or a clip system and check that the chair legs sit flat on the subbase to prevent tipping.

Keep chairs vertical by seating them firmly and re-checking after several ties are made. If chairs deform when tied, replace them—don’t gamble on bent supports under the weight of wet concrete.

Final checks before pour

Walk the slab and verify concrete cover at random points with a gauge or ruler so the rebar is the right distance from the surface. Also confirm the reinforcement pattern, lap lengths, and any spacers or sleeves are in place.

Test chairs by applying hand pressure to a couple of spots to mimic the pump and screed load; they should not move or collapse. Make sure forms are braced and straight, and that pump and access paths are staged to avoid trampling chairs during the pour.

Confirm utilities and embed items are positioned and protected, and take photos of the final condition. If anything looks compromised or critical dimensions are off, stop and call the inspector or a pro before pouring.

Tools and materials checklist

This section lists the essential tools, fasteners, chair types, and protective gear you’ll need for typical installations. Having the right gear on hand keeps projects safe and moves smoothly.

With a practical checklist, you can prep before you start and avoid trips back to the toolbox. Being prepared saves time, reduces mistakes, and helps you work safely on busy jobsites.

Essential tools and safety gear

Bring the basics you actually use on site. Don’t overpack, but don’t show up short either.

- Tie wire & snips Fastens rebar and small fittings. Use 16–18 gauge for most jobs. Keep extra spools; they run cheap but you’ll go through them.

- Linesman pliers Grips, twists, and cuts tie wire. Look for 8–10″ for leverage. Clean and oil them to avoid rust on long jobs.

- Hammer tacker Secures vapor barriers and insulation quickly. Use heavy-duty tacks for exterior work. Rent one for big jobs if you don’t use it often; $10–$25/day typical.

- Work gloves Protect hands from cuts and abrasion. Go leather or heavy synthetic for durability. Bring several pairs; change if wet or torn.

- Safety glasses Protect against dust and flying debris. Choose ANSI-rated clear or tinted lenses. Keep spare lenses on hand for scratched ones.

- Measuring tape Accurate layout starts here. Use 25–30 ft tapes with a durable blade. Fasten to belt so you don’t lose it on ladders.

- Chalk line Marks long straight lines quickly. Use both snap and refillable styles. Carry extra chalk since it blows away on windy days.

- Respirator or dust mask Filters dust and fumes on cutting or old materials. Use N95 for dust, cartridge respirators for solvents. Replace cartridges per manufacturer or when breathing is harder.

- Small pry bar Removes nails and adjusts trim or chairs. A 12–18″ bar covers most tasks. Don’t use for heavy prying beyond its rating.

Choosing chair sizes and extras to bring

Order chairs to suit the rebar size and pour height you expect. A good rule is one chair per 1–1.5 square feet (about 0.1–0.14 m²) for standard slabs; increase density near openings and edges.

Bring a mix: low chairs (10–20 mm) for shallow cover, medium (25–40 mm) for typical slabs, and tall chairs (50–75 mm) for thicker pours or raised mat supports. Always round up quantities by 10–20% to allow for cuts, waste, and changes on site.

Pack extras: a box of plastic or concrete block chairs for quick fixes, several adjustable chairs for irregular areas, and tie-off clips or rebar caps. Keep a small toolkit for onsite adjustments and a handful of backup sizes so you don’t delay the pour.

Visual checkpoints and inspection guide

This section presents a photo-oriented checklist and measurable tolerances to verify before and during the pour. It helps inspectors spot concrete defects early. Follow clear visual cues to ensure consistency.

Having defined tolerances in sight makes decisions faster on site and reduces rework. With the photo cues, you can compare real conditions to targets as you work. This helps you deliver safer, more reliable pours.

On-site visual checklist and quick-reference diagram Use the attached quick-check list and on-site cues to verify conditions during placement. The items below translate plan drawings into observable cues you can confirm at a glance. Keep a quick photo record of readings and any deviations for the pour record.

- Chairs and supports are upright, fully seated on chair bases, and the bar is held at the correct height above the forms.

- Concrete cover is verified at mid-span, lap zones, and edges; no exposed ends or inadequate cover that would compromise durability.

- Rebar is straight, untwisted, and not displaced at laps or corners; no bent or kinked bars that could reduce strength.

- Rebar spacing is within the plan tolerances and evenly distributed across the grid or layout.

- End laps and stirrups are intact, properly aligned, and protected from damage during placement and finishing.

- Chairs and supports do not interfere with the formwork or pour path; no chairs resting on forms that would tilt the bar.

- Any potential crowding of bars, ties, or accessories near the surface is corrected before the pour progresses.

- All measurements are documented with a photo and labeled for the pour record, including any deviations from the drawings.

Do the checks right before the pour, and again once reinforcement is in place. Document readings with a quick photo and note the measurements for the pour record.

Safety note: Wear appropriate PPE (gloves, safety glasses, hard hat where required) and keep hands and feet clear of any open forms or exposed rebar to avoid injury. Do not lean on or strike in-place chairs or supports during finishing, and stop the pour if a major discrepancy is found until corrected.

Common visible defects to look for

Walk the slab and scan for anything out of place. Look for tilted chairs, crushed or missing supports and rebar that has shifted from its intended line. These are the usual suspects that bite you after the pour.

Check for inadequate concrete cover—bars too close to the face or exposed ends are a guarantee of future corrosion. Also watch for bent or displaced bars at laps and corners; they reduce capacity and make finishing uneven.

If you see any of these, stop and mark the area. Fix the support or reposition the bar before the truck arrives. Small problems now save big repairs later.

Measuring cover and alignment on-site

Carry a tape, a pocket depth gauge or a small straight-edge and feeler gauges. Measure cover at several spots: mid-span, lap zones and at edges. Use the straight-edge to check that chairs and supports hold the bar at the correct height.

For alignment, snap quick chalk lines or use a string to verify bar runs are straight and evenly spaced. Confirm lap lengths and stirrup positions with a tape. If cover is off by more than the tolerance on your drawings, adjust supports or add cover material.

Do the checks right before the pour, and again once reinforcement is in place. Document readings with a quick photo and note the measurements for the pour record.

Common mistakes and how to avoid them

Common installation errors often lead to weak bonds, leaks, or failed longevity. By spotting and fixing these mistakes early, you can ensure a durable, properly seated installation. Plan your steps, measure carefully, and follow best practices to avoid rework.

Understanding the typical missteps helps you troubleshoot on site and adjust techniques before committing materials. This saves time, reduces waste, and results in a safer, longer-lasting job. Sticking to correct procedures reduces callbacks and keeps projects on schedule.

Underestimating construction loads

Don’t assume a lightweight chair will hold up when the truck pours. Concrete applies a lot of lateral and vertical pressure, especially during a fast pour. Pick chairs rated for the expected pour depth and the weight of wet concrete.

Space matters. Closer chair spacing reduces point loads and keeps the mesh at the correct elevation. For heavier pours or tall walls, use heavy-duty or steel chairs and add temporary shoring under long spans. Never stack flimsy chairs — they crush and sink, ruining cover and causing rework.

Improper tying and unsecured chairs

Loose chairs move when the concrete flows. Tie chairs to the rebar with proper tie wire or use purpose-made clips. Wrap the wire tight and twist it so the chair can’t shift under vibration.

Anchor chairs to nearby formwork or block them with stakes on open slabs. For critical areas use double ties: one to hold elevation and one to stop lateral movement. A few well-placed ties save hours of patching later. Check ties after the first bucket to catch any movement before it’s too late.

Maintenance, removal, and post-pour considerations

After the pour reaches the specified cure, remove temporary supports as instructed and protect the surface during final curing. Follow curing precautions to minimize cracking, such as controlling moisture and temperature. Keep track of what was removed and when to support inspection records.

This matters for DIY and job sites because proper removal timing and curing practices prevent costly failures and ensure safety. Clear notes and a simple log help inspectors verify compliance with building codes and project specs.

Handling chairs left in-place vs. removable systems

Leaving non‑corrosive chairs in the slab saves time and avoids damage from prying them out. Plastic and stainless chairs are common for that reason. They become part of the concrete and usually cause no harm when chosen correctly.

Removing temporary steel supports can give you cleaner finishes and easier repairs later, but it takes labor and risks spalling if you pry too soon. If you plan to remove, wait until the concrete has enough strength and use proper cutting or pulling tools to avoid cracking.

Pick the method that matches the job: use embedded non‑corrosive chairs where access and finish aren’t critical. Remove temporary steel when future work or inspections demand a clean underside or when corrosion is a concern.

Curing effects and monitoring for early corrosion

Proper curing keeps moisture in and protects steel during the critical early days. Wet curing, curing compounds, or polyethylene sheeting all work if applied immediately. Keep foot traffic light until the concrete reaches the specified strength.

Watch for early warning signs: rust staining at chair locations, efflorescence, or hairline cracks near supports. Check exposed edges and any penetrations daily for the first week and then weekly until full cure.

If you see rust or staining, document it with photos and notes, mark the area, and consult the spec or engineer. Early action—cleaning, patching, or additional protection—prevents bigger repairs later.

Conclusion

Keeping rebar off the ground isn’t optional. It protects the steel from moisture and dirt, helps the concrete flow and cure properly, and keeps your structure looking straight and lasting longer.

Now do this: verify the bar and chair specs match your plan, lay out the grid with proper spacing, position chairs and supports so every rebar leg sits firmly, run a quick dry layout with string lines to confirm alignment, secure everything with ties, and do a brief lift-and-check to ensure clearances are maintained before you pour. Keep a tight sequence so nothing shifts during concrete placement, and double-check against your plan one final time before you pour or strike forms.

Common mistakes to avoid are using the wrong chair type or size, letting chairs sink or tilt, and spacing the chairs too far apart or too close together. Don’t neglect safety: wear gloves and eye protection, keep forms and edges protected, and never rush the pour. If you’re unsure about the load, code requirements, or large-scale work, call in a pro rather than guessing. When you follow these steps and stay attentive, you’ll get a clean, durable result that will stand up to time and use.

FAQ

1. Why do I need rebar chairs and supports off the ground?

So the steel doesn’t sit in mud or sit on the ground and rust. It keeps the rebar clean and ready for concrete. If it’s not off the ground, you’ll have bad embeds and weak spots.

2. How do I choose the right height for chairs?

Match the chair height to how tall your concrete will be. Don’t guess—measure the form and the rebar bundle. Too high and the rebar won’t get encased; too low and it won’t be in the concrete.

3. Where should I place chairs and supports?

Place chairs at all major intersections and every 2–3 feet along long runs. Put them under the rebar so the bars stay centered in the slab. Don’t let chairs wobble or slide when you pour.

4. What are the common mistakes to avoid?

Avoid stacking chairs or tying the rebar to chairs loosely. Don’t leave gaps where steel touches dirt or form edges. If the rebar sits on the ground, you’ll end up with rusted steel and weak spots in the slab.