Introduction

A vapor barrier under concrete slabs is a sheet or layer placed beneath the slab to slow or stop moisture from the ground. Use it when the soil is damp, there is a chance of rising moisture, or the project requires a dry, stable floor. Check local guidance and the manufacturer’s installation instructions for specific details on spacing, overlaps, and handling during pour.

Before you install, prepare the subgrade, clean debris, and plan the barrier layout with proper overlaps at seams. Have a sharp utility knife, tape, manufacturer-approved barrier material, and temporary supports ready to keep the barrier flat as you work. During installation, overlap seams, seal edges, and protect the barrier from punctures during the pour while following site-specific guidelines.

Key takeaways

- Determine if vapor barrier is required per local code and moisture risk.

- Plan substrate prep: clean debris, dry surface, and repair cracks before barrier placement.

- Use approved polyolefin or PE barriers; overlap seams and seal with tape.

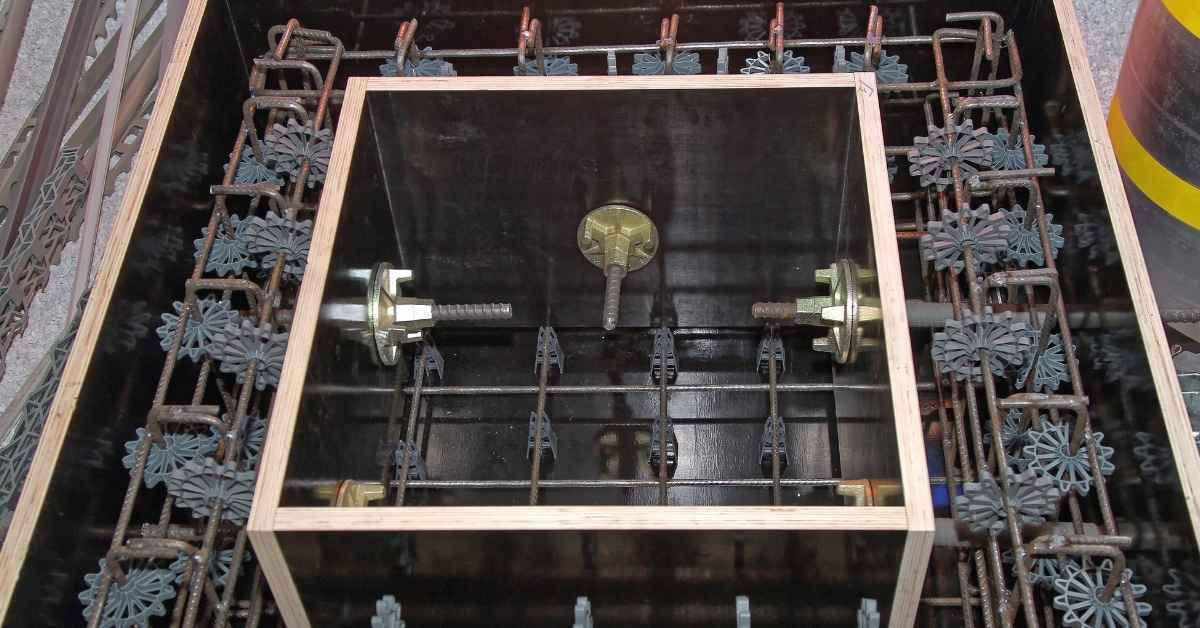

- Install with proper under-slab clearance, avoid punctures from penetrations or rebar.

- Seal penetrations and joints with compatible sealant and tape during placement.

- Safety: wear gloves, eye protection, and monitor for moisture-related hazards during backfill.

Table of Contents

- Introduction

- Key takeaways

- Why a Vapor Barrier Matters

- Materials and Products: Choosing the Right Vapor Barrier

- Planning and Pre-Installation Checklist

- Step-by-Step Installation Process

- Dealing with Penetrations, Joints, and Repairs

- Safety, Compliance, and Quality Control

- Cost, Project Scale, and Decision Guidance

- Long-Term Performance and Maintenance

- Conclusion

- FAQ

Why a Vapor Barrier Matters

A vapor barrier under slabs serves to limit moisture migration from the soil into the concrete and interior finishes, helping protect flooring and reducing excess curing moisture that can affect long-term durability. It distinguishes vapor retarders from true vapor barriers by material permeability and intended performance, with low-permeance barriers favored under slabs for most projects. Failing to install one can lead to elevated moisture in the slab, cupping or curling of flooring, adhesive bond problems, and potential mold growth that impacts indoor air quality.

Reference standards such as ASTM E1643 and ASTM E1745 when evaluating subfloor performance, and consult a design professional for complex or high-moisture conditions to ensure the right specification is chosen. Consider practical aspects like slab-on-grade layouts, soil prep, seam overlaps, puncture protection, and sealing around penetrations to maintain continuous moisture control. When projects are large, high-rise, or involve radiant heating or unusual subgrades, seek professional guidance to align with any engineered requirements or local rules.

When to Use a Vapor Barrier

A vapor barrier under your concrete slab is crucial for protecting your flooring and the entire structure from moisture damage. Here are some scenarios where you should definitely use one:

Indoor slabs: If your slab is indoors, like in a basement or garage, you need a barrier to prevent moisture from the soil below from migrating into your living space.

Slabs over contaminated soils: If your site has contaminated soil, a vapor barrier helps prevent harmful gases from entering your home. Combine it with an appropriate gas mitigation system for best results.

Moisture-sensitive flooring: If you’re installing moisture-sensitive flooring like hardwood or certain types of tile, a vapor barrier is essential to protect your investment and ensure long-term performance.

High water table or slab-on-grade with HVAC: In areas with high water tables or when your slab is poured directly on the ground (slab-on-grade) with HVAC systems, a vapor barrier helps control moisture and prevent mold growth.

Benefits and Limitations

A vapor barrier offers several performance benefits when installed correctly:

Vapor control: The primary function of a vapor barrier is to limit moisture migration from the soil into your concrete slab and interior finishes, protecting your flooring and supporting long-term durability.

Radon/soil gas mitigation: When combined with appropriate systems, a vapor barrier can help prevent harmful gases like radon from entering your home, enhancing indoor air quality.

However, it’s essential to understand the limitations of a vapor barrier:

Not a structural waterproofing system: A vapor barrier is not designed to stop liquid water or high hydrostatic pressure. For those conditions, you’ll need additional waterproofing measures.

Potential effects on slab bond: If not installed properly, a vapor barrier can interfere with the bond between your concrete and the subgrade, potentially compromising the structural integrity of your slab.

Materials and Products: Choosing the Right Vapor Barrier

Compare material types such as polyethylene sheets by thickness, engineered membranes, and self-adhered sheets, noting where each is commonly used and how they perform under typical subgrade conditions. Look at permeability ratings and how they align with project goals like MVER targets and moisture control, then translate that into practical selection decisions. Assess puncture resistance, surface protection, and how the material will hold up during subgrade prep and backfill work.

Understand seam and installation requirements, including overlaps, taping or heat-welding, and compatibility with primers or backfill products. Keep in mind code expectations, standards references, and any manufacturer testing that informs suitability for your climate and soil. Weigh pros, cons, and cost considerations to balance convenience, durability, chemical compatibility, and long-term performance.

Material Specs and Standards Explained

The right vapor barrier material ensures a durable, effective seal under your concrete slab. Here’s what to look for:

- Thickness (mil): 6–20 mil. Thicker isn’t always better; it can wrinkle and cause issues. Check project specs.

- Perm Rating: Lower is better, ideally <1. A high perm rating lets moisture through.

- Puncture Resistance: High. Subgrade debris can puncture membranes. Look for ASTM D7465 ratings of 200+ lbs/inch.

- ASTM/ISO Standards: Check for ASTM E1643, ISO 15185. These ensure the membrane meets international standards.

- Chemical Compatibility: Ensure it’s compatible with your soil and aggregate. Some membranes can degrade over time if not.

Accessories, Sealants, and Repair Products

To install a vapor barrier correctly, you’ll need some ancillary items. Here’s what to consider:

Tapes: Use them for seaming and lapping. Make sure they’re compatible with your chosen membrane.

Mastics: These seal around penetrations like pipes or wires. Choose one that sticks well to your membrane.

Boots, Patch Kits, Termination Flashings: These protect vulnerable areas and prevent moisture ingress. Ensure they’re designed for use with your chosen vapor barrier.

Planning and Pre-Installation Checklist

Start with a site conditions assessment that notes soil type, moisture sources, drainage plans, and any utilities or hazards that could impact barrier performance. Review drawings and specifications to confirm slab thickness, reinforcement, control joints, and any sub-slab fill requirements impacting barrier placement. Define the coverage scope and detailing, including overlaps, sealant methods, and how barriers integrate with footings and wall interfaces.

Coordinate slab-on-grade versus suspended slab specifics, pour sequencing, and curing needs, making any design changes that affect barrier layout. Identify local code requirements, permit steps, warranty implications, and testing plans with clear responsibilities and timelines. Select materials and installation planning details like barrier type, thickness, permeability, fasteners, and edge detailing, plus site-prep steps and crew roles to ensure smooth execution.

Site Preparation Requirements

Before laying down your vapor barrier, ensure the site is well-prepared to prevent issues later on.

- Clean site: Remove all debris, rocks, and vegetation. A clean site ensures better adhesion of the barrier.

- Graded aggregate or sand base: Prepare a level base using compacted aggregate or sand to provide a smooth surface for the barrier.

- Compacted soil: Ensure the soil is properly compacted to prevent settling and shifting that could damage the barrier.

- Moisture content check: Test the moisture content of the soil. Excessive moisture can lead to blisters or delamination of the barrier.

- Cushion layer (optional): If using a tough membrane, you might not need a cushion layer. However, for delicate membranes, a 2-4 inch layer of sand or aggregate can protect it from damage during concrete pouring.

- Slab edges: Ensure slab edges are well-defined and free from debris to prevent barrier tears.

- Existing utilities/hazards: Identify and mark any underground utilities or hazards that could puncture the barrier.

- Drainage plan check: Confirm that the drainage plan is in place to prevent water pooling under the slab.

Quick rule: A well-prepared site ensures a successful vapor barrier installation and extends its lifespan.

Tools and Materials Checklist for Contractors and DIYers

Having the right tools and materials on hand ensures a smooth vapor barrier installation.

- Tape measure: Essential for accurate cutting and fitting of the barrier.

- Utility knife or scissors: For cutting the barrier to size. A sharp blade is crucial to prevent tears.

- Roller (optional): Helps apply sealants, adhesives, or mastic evenly. Not always necessary but can make the job easier.

- Broom: Useful for sweeping the site clean before laying down the barrier.

- Tape: For sealing seams and edges of the barrier to prevent moisture intrusion.

- Mastic or sealant: Used for sealing overlaps, edges, and penetrations. Choose one that’s compatible with your barrier material.

- Gloves and safety glasses: Protect yourself from cuts, punctures, and chemicals during installation.

- PPE (Personal Protective Equipment): Depending on the materials used, you might need additional PPE like a respirator or protective clothing.

- Material quantities: Estimate barrier size based on slab dimensions. Add 10-20% extra for waste and cuts. For sealants/mastic, follow manufacturer’s recommendations based on seam/edge length.

Quick rule: Having the right tools and materials ready ensures a quick, efficient installation with minimal waste and rework.

Step-by-Step Installation Process

Define the exact layout plan by mapping slab dimensions, load zones, and the barrier footprint with adequate overlaps and clean edges before any material goes on site. Check substrate prep and material prep conditions to ensure a clean, dry, and flat base, addressing dust, moisture, laitance, and correct barrier type and thickness. Plan seam overlaps, taping methods, and fasteners so edges remain secure without creating trip hazards.

Protect the barrier during the pour with temporary edge supports, exclusion zones, and procedures that shield it from damage during equipment movement and concrete placement. Manage penetrations, terminations, and quality-control checkpoints by detailing wall connections, pipe sleeves, and mid-process inspections to verify continuity and integrity of the barrier. Schedule final checks to confirm there are no gaps or punctures before finishing the slab.

Step-by-Step Installation Process

The following steps guide you through installing a vapor barrier under your concrete slab, ensuring a solid foundation and protecting your home from moisture damage.

- Preparation: Ensure the subgrade is clean, dry, and flat. Remove any dust, moisture, or laitance using a shovel or broom.

- Layout: Mark out the slab dimensions and identify load zones. Map out vapor barrier placement with appropriate overlaps (12″ minimum) and edges secured with tape or fasteners.

- Main Work: Roll out the vapor barrier sheets, following your layout plan. Use adhesive or tleece method for seam overlap (6″ minimum). Seal joints using recommended sealant.

- Protection: Install temporary edge supports and rigid forms to shield the barrier from damage during equipment movement and concrete placement.

- Final Checks: Inspect for penetrations, install terminations at walls and around pipes. Check moisture/vapor barrier integrity before pouring concrete.

Laying, Seaming, and Overlaps

Properly laying, seaming, and overlapping vapor barrier sheets ensures continuous coverage and prevents moisture from migrating through the slab.

Sheet Layout: Start at one corner of the slab, unrolling sheets in a staggered pattern to ensure full coverage. Allow for 12″ minimum overlaps between sheets.

Seaming Techniques: Use tape, heat, or adhesive methods to seal seams. Apply seam sealant according to manufacturer’s instructions, ensuring it covers the entire seam width (6″ minimum).

Press firmly along the seam to ensure a tight bond and prevent delamination.

Terminating Edges and Integrating with Foundation Elements

Properly terminating the vapor barrier at edges and integrating it with foundation elements prevents moisture intrusion and ensures structural integrity.

Edge Termination: Extend the vapor barrier 6″ up the foundation wall. Secure it using tape or fasteners, ensuring a tight seal. Follow ASTM E1643 guidelines for edge termination.

Integration with Foundation Elements: Coordinate with structural bond requirements. For footings, extend the barrier under the footing and up the side. For control joints, ensure the barrier extends into the joint and is properly sealed.

Consult a professional if you’re unsure about integration points or structural bond requirements.

Dealing with Penetrations, Joints, and Repairs

Identify penetrations such as pipes, conduits, sleeves, and joints that intersect the barrier, noting sizes, materials, and movement requirements to select compatible sealing methods. Outline sealing options for penetrations, including rigid sleeves, water-stop boots, gaskets, mastic, or self-adhesive membranes, ensuring compatibility to prevent moisture migration. Plan joint treatments for control, expansion, and construction joints, and decide whether to extend the barrier under or around joints to maintain continuity.

Set pre-pour checks and prep steps that prioritize clean, dry surfaces, debris removal, sleeve alignment, and clearance verification to prevent punctures during concrete placement. Include post-placement inspection and leak testing, with patching options for any damage, detailing curing considerations and how to verify barrier integrity before the final pour.

Sealing Penetrations and Clusters of Services

In areas packed with pipes, conduits, and sleeves like hospitals or labs, sealing penetrations is crucial. Use a combination of boots, collars, mastic, and patch methods.

Boots and Collars: Slip water-stop boots over pipes and secure with clamps. For sleeves, use rigid collars that fit snugly around the penetration.

Mastic and Patching: Apply mastic sealant around boots, collars, and any gaps. For damaged areas, patch with a compatible material before applying the vapor barrier.

Inspection and Repair Protocols

Before pouring concrete, inspect the area to ensure the vapor barrier’s integrity. Use this checklist at key stages:

- Pre-barrier installation: Check for clean, dry surfaces free of debris.

- Post-barrier installation: Verify proper sleeve alignment and clearances.

- Pre-concrete pour: Re-check all penetrations, joints, and barrier edges.

- Common defects: Look for punctures, tears, or lifted edges.

- Repair methods: Patch with compatible materials, reapply mastic if needed.

- Documentation: Record all repairs, their locations, and dates.

- Leak testing: Perform a water test to confirm barrier integrity.

- Post-repair check: Re-verify clearances and ensure no new damage.

Quick rule: Always re-check after any site activity to prevent punctures during concrete placement.

Safety, Compliance, and Quality Control

On-site safety basics include wearing PPE, proper handling of large vapor-barrier sheets, and storing materials to minimize damage and trip hazards. Implement hazard controls to keep walkways clear and reduce slip risks from weather or spilled debris, using edge protection as needed. Focus on material handling and setup, including unrolling discipline, cutting tolerance, overlaps, and secure seams to prevent gaps and wrinkles.

Comply with applicable ASTM specs and local codes, and document AHJ requirements that affect installation. Develop a quality-control and inspection plan with pre-install checklists, substrate moisture considerations, and seam integrity checks, plus rollback criteria if issues are found. Plan verification timing and documentation, identifying who signs off and what records (roll numbers, thickness, test reports) must be kept for future reference.

Common Mistakes and How to Avoid Them

Even experienced installers can make mistakes. Here are some common ones to avoid:

- Insufficient overlaps: Overlaps prevent moisture from getting under the barrier. Make sure they’re at least 6 inches wide.

- Damaged membrane: Cuts, tears, or wrinkles compromise performance. Handle sheets carefully and inspect before installing.

- Improper terminations: Edges must be properly terminated to prevent moisture intrusion. Follow manufacturer’s guidelines for edge treatments.

- Not accounting for substrate movement: Concrete slabs move. Use approved tapes or sealants at joints and control seams to accommodate this.

Preventing these mistakes ensures your vapor barrier works as intended.

Documentation and Sign-Off Procedures

Proper documentation is crucial for compliance, warranty eligibility, and future reference. Here’s a simple quality-control checklist:

Pre-installation: Photograph the area before installation. Check substrate moisture levels.

Installation: Document seam integrity with photos. Note any repairs made during installation.

Post-installation: Conduct a final walkthrough, noting any issues that arise. Keep records of roll lot numbers, thickness, and ASTM reports.

Sign-offs should be done by the installer or a designated representative, with records kept on file for future reference.

Cost, Project Scale, and Decision Guidance

Understand cost drivers such as material type, thickness, sealing and edge detailing, and any reinforcement, then estimate labor hours and rates for removal, site prep, and installation. Consider project scale factors from small DIY slabs to large commercial pours, and how footprint, subgrade conditions, and sequencing influence material waste and scheduling. Weigh residential versus commercial needs and how features like slope or corner detailing affect overall costs and protection layers.

Evaluate the DIY versus professional decision factors, including skill level, code requirements, warranty implications, and the risk of improper installation leading to moisture or floor issues. Plan budget contingencies, procurement tips, and potential time savings from prefabricated options while avoiding overconfidence on complex layouts. Identify situations where DIY is reasonable and where hiring a pro is warranted, and gather quotes with references to compare options.

Budgeting and Labor Considerations

The cost of installing a vapor barrier under your concrete slab varies based on several factors. Let’s break down the key elements to consider when budgeting.

Material Costs: The type of membrane (plastic or metal), its thickness, and whether it’s a vapor retarder or barrier will impact the price. Expect to pay more for thicker membranes and those with built-in adhesives.

Labor Costs: Estimate around 2-4 hours per 100 sq ft for removal, site prep, and installation. Labor rates vary by region, so get quotes from local pros.

Complexity also drives labor time. Expect more time (and cost) for slabs with many penetrations or challenging layouts.

When to Hire a Professional

While DIY is possible for simple, small-scale projects, there are times when hiring a pro is best. Here’s when to consider it:

Complex Penetrations: If your slab has many penetrations (e.g., plumbing, electrical), pros have the experience and tools to seal them properly.

Radon/Soil Gas Mitigation: In high radon areas or where soil gas mitigation is required, hire a pro to ensure your vapor barrier meets local codes and provides adequate protection.

Large Commercial Slabs: For large commercial projects, pros have the manpower and equipment to handle the scale efficiently. Plus, they’re familiar with commercial code requirements.

Warranty Requirements: If your project requires a warranty (e.g., new construction), hiring a pro ensures you get one. Many DIY jobs don’t qualify for warranties.

Long-Term Performance and Maintenance

Consider how the chosen vapor barrier impacts flooring warranties, supplier requirements, and documentation that may be needed for future claims. Establish a routine inspection plan and note what to look for, such as edge lift, punctures, chemical staining, or moisture-related changes, with simple moisture test reminders. Plan protective strategies for slab-edge terminations to prevent damage over time, using expansion joints, transition strips, or other protective details as appropriate.

Adopt maintenance and protection practices that minimize solvent exposure near the barrier and provide clear guidelines for remodeling scenarios that could affect the barrier’s integrity. Include repair and retrofit options, outlining when to patch or replace and how to address damage without compromising performance. Keep records of product data and installation steps to support future maintenance or warranty considerations.

Visual Checkpoints After Pour and During Occupancy

Inspect your concrete slab visually after pouring and during occupancy to ensure the vapor barrier is performing as expected. Here’s a checklist to guide you:

- Edge integrity: Check for any lifting, cracking, or separation at the edges. This could indicate damage during installation or settling issues.

- Flooring moisture symptoms: Look for signs of excessive moisture on top of your slab, like warping, buckling, or discoloration in your flooring. These can be early indicators of barrier failure.

- Condensation: Check for water droplets or condensation on the underside of the slab or on the vapor barrier itself. This suggests moisture is getting through.

- Edge terminations: Ensure they’re intact and properly sealed to prevent moisture intrusion at these vulnerable points.

- Penetrations: Inspect any penetrations (like pipes, wires) for proper sealing and ensure no gaps exist that could allow moisture entry.

- Joints: Check expansion joints for proper filling and maintenance. Cracking or open joints can let in water.

- Chemical staining: Look for discoloration on the slab surface, which might indicate chemical exposure or moisture issues.

- Moisture-related changes: Keep an eye out for any unusual bulging, cracking, or other signs of movement in your slab, which could signal underlying moisture problems.

Quick rule: Regular visual checks help catch issues early, preventing costly repairs and maintaining your vapor barrier’s effectiveness.

Warranty, Longevity, and Retrofit Options

Understanding warranties and expected service life helps you plan for your vapor barrier’s long-term performance. Here’s what to consider:

Warranties: Verify with manufacturers the warranty coverage for their vapor barriers. Some may cover only installation defects, while others might include moisture-related issues.

Expected service life varies by product and installation quality. On average, expect 25-50 years of service from a well-installed barrier. Regular inspections help ensure you get the most out of your investment.

Retrofit options: If moisture problems appear after construction, first assess the damage. Minor issues might be fixed with temporary solutions like sealants or additional barriers. Severe problems may require replacing the entire vapor barrier system.

Conclusion

Install it right and the slab stays dry, strong, and smooth. It protects the floor finish now and prevents costly moisture problems later.

Check the plan, pick the right barrier, measure and lay it flat with clean seams, seal all edges and penetrations, keep the surface clean and dry before pour, and protect the barrier during backfill. If you follow these steps in a steady sequence, you’ll beat moisture, reduce headaches, and avoid rework.

Common mistakes to avoid include skipping moisture testing or subgrade preparation, puncturing or wrinkling the barrier, using the wrong tape or seals, and rushing around penetrations without proper securing. Always keep PPE handy, store rolls on clean surfaces, and work from dry to wet areas to prevent damage. Fight the urge to skip steps—correct prep and careful installation save time and money in the long run.

If the project is large, complex, or you’re dealing with widespread penetrations or unusual site conditions, consider bringing in a pro for a quick review or assist in the critical steps. Stay steady, follow the plan, and you’ll finish with a durable, clean install that holds up under real use.

FAQ

When should I use a vapor barrier under a concrete slab?

Use a vapor barrier when moisture coming from the ground can affect your slab or flooring. If your site has a damp soil condition or you’re laying a moisture-sensitive finish, consider it. Always verify with the slab plan and local guidelines or manufacturer instructions.

What tools and materials do I need for installation?

Have plastic sheeting or a rated vapor barrier, tape for seams, fasteners or ballast as required, a utility knife, and a roller or squeegee for smoothing. Also have clean ground clean-up tools and a level to check placement. Check product labels and installation guides for exact requirements.

What prep work should I do before laying the vapor barrier?

Clear debris and sharp rocks from the subgrade. Level the area as much as possible and remove standing water. If you have penetrations or utilities, plan how the barrier will lay around them and note any required turning points or folds.

How do I install and seal the vapor barrier under the slab?

Lay the barrier with the smooth side up if specified. Overlap seams as directed and seal with compatible tape or seam adhesive. Keep the barrier flat and free of wrinkles; trim tight around edges and around penetrations as you go.

How should I terminate edges and handle penetrations?

Turn the barrier up against edges and foundations where required and secure per the manufacturer’s guidance. For pipes and conduits, cut clean holes or use protective sleeves and seal with approved sealant or compression fittings. Always follow product instructions for termination details.