Introduction

Concrete edge chipping near garages happens when traffic, moisture, freeze-thaw cycles, and weak edge support combine to break the thin, exposed rim of the slab. I’ll explain the common causes and practical fixes so you can stop new damage and protect the slab edge. This is written as a hands-on DIY approach you can use on a weekend.

Moisture getting under or through a chipped edge speeds deterioration and can ruin coatings if the surface isn’t prepared and the source isn’t fixed; check product labels and local rules for vapor and substrate requirements. You’ll hear about reinforcing options, load management, and surface prep so you can pick the right repair or armor for your garage edge and extend the life of floor coatings in high-stress spots.

Key takeaways

- Identify chip patterns near doors to distinguish impact damage from moisture-initiated cracking.

- Assess moisture ingress by checking damp spots, efflorescence, and floor slab seams.

- Choose patching or rebuild options based on edge depth, support, and movement.

- Apply protective coatings with proper surface prep, cure times, and compatibility checks.

- Prioritize proper drainage and moisture barriers to extend coating longevity.

- Follow safety protocols: mask, eye protection, and lockout controls during repairs.

Table of Contents

- Introduction

- Key takeaways

- Why Concrete Edges Near Garages Chip — Causes and Risk Factors

- How to Assess and Inspect Damaged Garage Edges

- Repair Options by Damage Level — from Patching to Full Edge Rebuilds

- Types of Protective Edge Coatings and Armor Systems

- Application Techniques for Coating and Armoring Garage Edges

- Long-Term Maintenance and Preventative Strategies

- Costs, Budgeting, and ROI for Edge Repairs and Armor

- Safety Measures, Common Mistakes, and Pre-Work Planning Checklist

- Conclusion

- FAQ

Why Concrete Edges Near Garages Chip — Causes and Risk Factors

Edges fail for a mix of mechanical, environmental, and construction reasons that act together rather than alone. Impacts from tires, dropped tools, and concentrated wheel loads create dents and micro‑cracks that concentrate stress at the thin edge geometry.

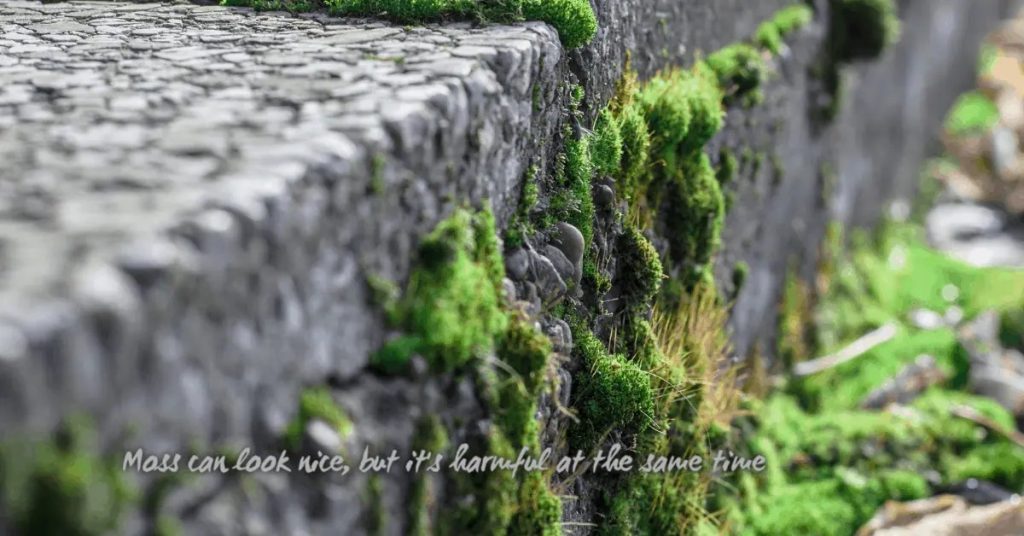

Water intrusion, freeze‑thaw cycles, and deicing chemicals accelerate deterioration by expanding cracks and weakening binder bonds; verify specific freeze‑thaw and salt resistance on product data sheets. Construction weaknesses—poorly supported forms, missing reinforcement, inadequate curing, and bad joint detailing at the garage interface—leave the edge unable to transfer load properly and speed up spalling.

Structural and placement causes

The concrete edge near your garage is vulnerable due to several reasons. Poor mix quality, with insufficient cement or aggregates, weakens the edge. Shallow finishing leaves the edge exposed to damage. Lack of reinforcement means there’s nothing to hold the concrete together when stressed. Unsupported slab edges can’t distribute weight evenly, leading to localized stress.

Lack of proper curing also plays a role. Concrete needs time and moisture to gain full strength. Inadequate curing leaves the edge weak and prone to chipping.

Use and environmental drivers

The way you use your garage and the environment it’s in both contribute to edge chipping. Vehicle turning forces put pressure on the edge, especially when parking or pulling out. Repeated impacts from dropped tools or equipment can cause micro-cracks that grow over time.

Moisture is another culprit. Water intrusion weakens the concrete and causes it to expand and contract with temperature changes. This freeze-thaw damage is a common cause of spalling and chipping in colder regions.

Design and construction errors to watch for

Several design and construction mistakes can lead to edge failure. Here are some to avoid:

- Missing edge forms: Without proper forms, the edge is weak and prone to chipping.

- Incorrect joint placement: Joints should be placed where concrete will naturally crack. Improper placement can lead to uncontrolled cracking and chipping.

- Inadequate consolidation: Concrete needs to be properly compacted to remove air pockets that weaken the edge.

- Lack of control joints at garage slab interface: Without these, stress from the garage slab can transfer to the edge and cause chipping.

By avoiding these common mistakes, you can help prevent edge failure near your garage.

How to Assess and Inspect Damaged Garage Edges

Start with a simple severity checklist and work methodically: note crack width, depth, spalling extent, substrate loss, and any vertical offset to standardize your findings. Use scaled photos and measurements so you can compare before/after and hand these to a contractor.

Perform a staged inspection—surface survey, drainage and moisture checks, gentle sounding for hollows, and alignment assessment—to isolate root causes like moisture intrusion, settlement, or repeated impact. Bring a moisture meter, tape, flashlight, and a phone for photos; if findings show deep edge loss, ongoing movement, or large cracks, consider a professional structural review rather than a DIY patch.

Step-by-Step Process

Follow these steps to thoroughly assess and inspect damaged garage edges, ensuring you gather all necessary information for a DIY fix or professional quote.

- Preparation: Gather tools (tape measure, moisture meter, flashlight, smartphone), wear safety gear (gloves, safety glasses).

- Initial surface survey: Walk the edge, note visible cracks, chips, and other damage. Take photos with a scale for reference.

- Moisture and drainage check: Use a moisture meter to test concrete. Check gutters, downspouts, grading around garage for proper water runoff.

- Substrate stability: Gently sound the edge with a hammer; listen for hollow areas indicating delamination or loss of substrate. Check for vertical displacement.

- Edge alignment and movement: Measure edge-to-edge and compare to original plans. Look for signs of ongoing movement like new cracks or shifted aggregate.

Visual checkpoints and signs of progressive damage

Use this checklist during your visual inspection to identify different failure modes and assess damage severity.

- Hairline cracks: Indicate early-stage damage. Check length, width, and direction for clues about cause.

- Spalling patterns: Irregular chipping or flaking may signal improper curing, freeze-thaw cycles, or moisture intrusion.

- Undermined aggregate: Exposed or missing aggregate indicates severe damage; check for loss of substrate and structural compromise.

- Rust staining: Suggests reinforcement corrosion, which can weaken the edge’s structure. Check for flaking or crumbling concrete around stains.

Quick rule: If you see multiple signs of progressive damage, consider professional intervention.

Measuring extent, depth, and structural impact

Accurately measuring damage helps determine repair needs and method. Use a tape measure to record crack widths, edge-to-edge distances, and any vertical displacement.

To estimate depth, gently sound the edge with a hammer. Listen for changes in tone indicating delamination or loss of substrate. Mark suspected areas for further investigation.

Structural impact: Check adjacent slabs for signs of movement. Measure edge-to-edge distances at multiple points to detect settlement or shifting.

When to call an engineer or contractor

Certain damage requires professional assessment and repair. If you notice any of the following, contact a pro before proceeding with DIY fixes.

Large edge loss: More than 1-2 inches of edge missing may indicate structural issues that need engineering evaluation.

Structural settlement: Signs include significant vertical displacement, sloping floors, or large cracks in walls. These could signal foundation problems requiring professional intervention.

Compromised reinforcement: Rust stains, exposed rebar, or crumbling concrete around reinforcement may indicate corrosion weakening the edge’s structure. A pro should assess and address this issue.

Repair Options by Damage Level — from Patching to Full Edge Rebuilds

Match method to damage: minor chips and hairline cracks usually take a temporary patch or surface repair, mid‑range delamination suits polymer‑modified mortars, and structurally compromised edges need bonded rebuilds or partial replacement. Define the damage first—surface vs substrate—so the repair material and prep are appropriate.

Prepare the substrate by cleaning, beveling, and priming per the repair product instructions; for full edge replacements install formwork and dowels to tie new edge into existing slab and check compatibility of bonding agents. When in doubt about mixing or cure guidance, consult the manufacturer instructions and plan for access, downtime, and any required reinforcement to prevent repeat failures.

DIY and temporary patch methods

For minor surface chips and hairline cracks, a quick DIY fix can buy you time until a proper repair. Here’s how:

Clean the area with a wire brush to remove loose material. Use a bonding agent like an acrylic primer to prepare the substrate. Apply a patch mortar, mixed according to the package instructions, and trowel it into the damaged area.

For seasonal fixes or when you’re short on time, this method works well. But remember, it’s only a temporary solution. Inspect regularly and address any recurring issues promptly.

Rebuilds and professional edge repairs

When the damage is deeper, like delamination or partial exposure to moisture, a rebuild might be necessary. Here’s how:

First, prepare the substrate. Remove all loose material, clean the surface, and apply a bonding agent. Then, build forms to contain the new concrete.

Mix your concrete according to the required strength. Pour it into the forms, vibrating as you go to remove air pockets. Insert reinforcing dowels at regular intervals for added strength.

Allow the concrete to cure properly, following the manufacturer’s guidelines. This ensures long-term durability and prevents future issues.

Structural anchoring and stitching techniques

For severe cases where the edge is structurally compromised, you’ll need to tie the repaired section back to the main slab. Here’s how:

Drill holes into the existing concrete at regular intervals. Insert dowels or use epoxy to anchor the new concrete to the old. This reinforces the bond and prevents further delamination.

Concrete stitching can also be used. Drill overlapping holes along the crack, insert a grout-filled sleeve, then fill with a high-strength epoxy or grout. This ties the concrete back together, preventing further cracking.

These methods require professional knowledge and tools. If you’re unsure, consult a structural engineer or hire a professional contractor.

Types of Protective Edge Coatings and Armor Systems

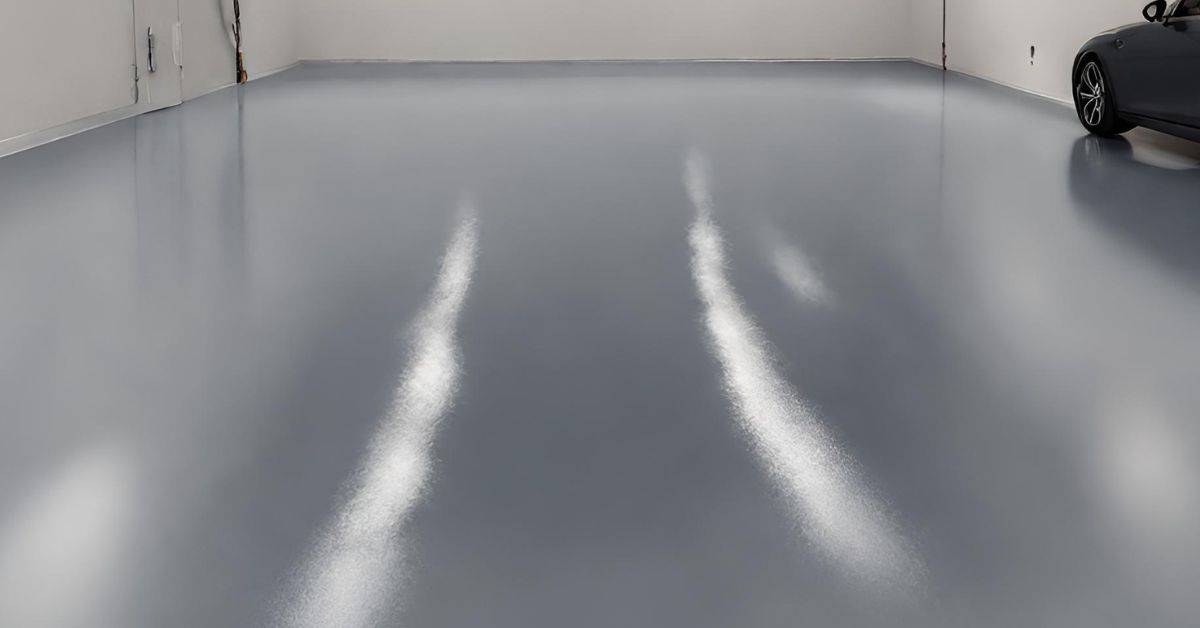

Protective options range from chemical coatings (epoxies, polyurethanes) and elastomeric membranes to cementitious overlays and physical edge guards made of metal or polymer. Each option trades off impact resistance, flexibility, adhesion needs, and installation complexity—check product labels or data sheets for adhesion, UV tolerance, and recommended substrates.

Coatings and membranes control moisture and bridge small cracks while rigid armor guards take the direct impacts but need proper mechanical fastening and sealing at fasteners. Choose by use case: heavy vehicle contact and salt exposure favor robust armor plus a waterproof membrane; light traffic and aesthetic needs may be served by high‑performance coatings—verify maintenance cycles and recoat intervals in product literature.

Chemical coatings (epoxy, polyaspartic, polyurethane)

Chemical coatings like epoxies, polyaspartics, and polyurethanes are great for protecting garage edges. They form a strong bond with concrete, sealing it against moisture and chemicals.

Flexibility is key here. These coatings can stretch and flex with the concrete, preventing cracking at the edge. But they need proper surface preparation to adhere well. Scrub, clean, and let the surface dry before applying.

Epoxies are tough but can yellow over time. Polyaspartics cure fast and stay clear, while polyurethanes offer excellent UV resistance for outdoor edges.

Overlays and membranes

Thin overlays and elastomeric membranes restore thickness to worn edges and provide a seamless surface. They’re like a second skin for your concrete.

Elastomeric membranes flex with movement, bridging minor cracks and preventing new ones from forming. They also resist UV damage, making them suitable for outdoor use. But they need proper substrate preparation to stick well.

Cementitious overlays are thicker, providing more protection but requiring careful application to avoid delamination. Wear-resistant overlays, like polyaspartic or polyurethane, offer excellent abrasion resistance for high-traffic areas.

Physical edge guards and mechanical armor

Metal angles, plastic profiles, and bolt-on guards are your first line of defense against impact damage. They take the brunt of vehicle doors and shopping carts.

Metal guards offer excellent durability but can rust if not properly treated or installed with a gap for expansion. Plastic profiles resist corrosion but may degrade under prolonged UV exposure. Bolt-on guards are versatile, fitting various edge thicknesses.

These guards can be combined with coatings for added protection. Just make sure the coating can bond well to the guard material. Always follow manufacturer’s installation instructions for best results.

Application Techniques for Coating and Armoring Garage Edges

Proper application starts with clear goals: pick a system designed for moisture resistance and impact where needed, and read the manufacturer instructions for compatibility and cure windows. Surface prep is critical—degassing oil, removing loose concrete, testing moisture, and profiling the concrete for good adhesion.

Prime with a compatible primer and follow sequence: seal seams and joints, apply coating to the required film thickness, then install edge guards using rated fasteners and seal around anchors to prevent water paths. If you’re unsure about fastener type, embedment depth, or cure times, consult the product technical data sheet and plan a post‑install inspection and touch‑up schedule.

Surface preparation and profiling best practices

Before applying any coating, it’s crucial to prepare the concrete surface properly. Start by removing all loose material using a wire brush or power washer.

Mechanical profiling or acid etching helps create a better bond for your topcoat. Choose one based on your edge condition and desired profile depth.

The goal is to achieve an open, porous surface that maximizes adhesion. Test the surface with water – if it beads up, you need more profiling.

Priming, detailing, and transition treatment

Choose a primer that’s compatible with both your concrete substrate and chosen topcoat. This ensures a strong bond between the two.

At the edge, detail fillets and chamfers to create a smooth transition from vertical to horizontal surfaces. This helps prevent delamination at these critical points.

Seams, expansion gaps, and transitions need special attention. Apply waterproof seam sealants or caulking here to ensure seamless moisture barriers.

Installing and anchoring edge guards

Lay out your edge guards, ensuring they’re level and evenly spaced. Use a fastener with good corrosion resistance to prevent long-term issues.

Embed the fasteners deep enough to provide solid support but not so deep that they cause stress points in the concrete. Seal around anchors to prevent moisture intrusion.

Install guards in sequence, following the manufacturer’s guidelines for mixing and application. This helps avoid pinholes and ensures a strong bond with your topcoat.

Long-Term Maintenance and Preventative Strategies

Create a simple, regular maintenance rhythm: seasonal visual checks, prompt crack sealing, joint upkeep, and targeted touch‑ups where traffic concentrates wear. Keep notes on condition and dates so you can spot progression instead of one‑off fixes.

Manage loads and winter care—avoid repeated parking on a thin unsupported edge, remove deicers promptly when possible, and use compatible sealants at joints to keep moisture out. If you see active movement, widening cracks, or recurring spalls, escalate to a professional before small damage becomes a rebuild; document observations to help decide timing and scope.

Routine inspection and maintenance checklist

Use this checklist every 6 to 12 months to keep your garage edge in top shape.

- Coating condition: Check for peeling, flaking, or discoloration. If more than 5% is affected, consider recoating.

- Small spalls: Look for tiny chips or cracks. Ignoring these can lead to bigger problems.

- Joint sealant integrity: Ensure joint filler isn’t cracked, missing, or crumbling. Replace if necessary.

- Drainage near the slab edge: Make sure water flows away from the garage. Standing water can cause erosion and movement.

- Edge alignment: Check for signs of substrate movement like tilting or warping. If noticed, consult a professional.

- Moisture intrusion: Inspect for dampness, mold, or mildew. These can indicate water penetration.

- Crack progression: Measure any cracks to monitor growth. Even hairline cracks need attention.

- Joint cleanliness: Ensure joints are free of debris. Dirt reduces adhesion and joint performance.

Quick rule: Address any issues found during the inspection promptly to prevent further damage.

Seasonal and weather-related precautions

Winter’s freeze-thaw cycle is tough on concrete edges. Here’s how to protect yours:

Use alternatives to salt: Rock salt can accelerate deterioration. Consider pet-friendly, eco-friendly deicers instead.

Before the first freeze, ensure your edge coating is in good condition and all cracks are sealed. This helps prevent moisture intrusion.

Minimize freeze-thaw cycling: Keep snow and ice from building up on edges. Regularly clear them to reduce stress caused by thawing and refreezing.

When and how to recoat or refresh protections

Regularly inspect your garage edge for signs it’s time to recoat, patch, or replace guards:

Coating: If more than 5% of the coating is peeling, flaking, or discolored, it’s time for a new coat. Also, recoat if the surface feels rough or gritty.

Patching: Address any small chips or cracks promptly to prevent them from growing and causing more damage.

Guard replacement: If your edge guards are bent, broken, or no longer fit securely, replace them. Damaged guards offer reduced protection.

Costs, Budgeting, and ROI for Edge Repairs and Armor

Costs hinge on damage extent, material choice, labor, access, and any permit or HOA constraints; quantify the edge area and describe scope when requesting bids. Create a standardized request that lists surface prep needs, expected life, and warranty questions so estimates are comparable.

Judge value by projected service life and maintenance frequency rather than headline price—longer‑lasting armor with higher initial cost can reduce repeat repairs. Note potential hidden expenses such as removal of loose concrete, edge reinforcement, or special access; ask contractors to break out these items so you can run simple ROI comparisons.

What influences cost and how to collect estimates

The cost of repairing and armoring your concrete edge depends on several factors. Here’s what you need to document for bids:

Damage extent and edge area: Measure the length and width of damaged areas. More damage means higher labor and material costs.

Material choice: Different repair mortars, coatings, and armor systems have varying prices. Get quotes for each to compare.

Labor hours: Estimate how long repairs will take based on the extent of damage. More time means higher labor costs.

Budgeting checklist and cost-saving strategies

Use this checklist when planning your budget to ensure you’ve considered all factors and explored cost-saving options:

- Combine repairs: If you’re already doing other slab work, combine the tasks to save on labor.

- Off-season scheduling: Schedule repairs during slower periods (e.g., winter) for lower prices.

- Material balance: Choose materials that offer good longevity despite higher upfront costs.

- Access/working conditions: Consider if special equipment or extra labor is needed due to access issues.

- Permit/HOA requirements: Check if permits are needed and if your HOA has any rules about repairs.

- Edge prep: Include removal of loose material, profiling, and surface preparation in your budget.

- Reinforcement: Consider adding edge reinforcement to strengthen the repair.

- Scaffolding/access equipment: If needed, factor in rental or purchase costs for equipment.

- Disposal: Include costs for disposing of removed concrete.

- Downtime: Consider any lost garage use time during repairs.

Quick rule: Always get at least three written quotes to compare. Review contract terms carefully before signing.

Safety Measures, Common Mistakes, and Pre-Work Planning Checklist

Plan safety: use appropriate PPE, control dust and fumes with ventilation or respirators, cordon the work area, and protect adjacent surfaces and landscaping. Check cure‑time restrictions so no one drives on or disturbs a repair during the critical initial period.

Avoid common errors like skipping substrate prep, using the wrong cleaners or moisture barriers, or rushing cure times—each undermines adhesion and long‑term performance. Run through a pre‑work checklist that includes moisture testing, tool and ventilation setup, waste containment, and a clear traffic plan to minimize rework and exposures.

Safety protocols and personal protective equipment

Before you start any work, ensure you’re protected from potential hazards.

- Wear a respirator: Concrete dust is harmful. Use a fit-tested mask with organic vapor cartridges.

- Eye protection: Safety glasses or goggles to protect your eyes from debris and chemicals.

- Gloves: Protect your hands from chemicals, solvents, and rough surfaces.

- Ventilation: Use fans or dust extractors to control fumes and dust while working with coatings.

- Containment: Seal off adjacent areas to prevent dust and debris migration.

- Protective clothing: Wear long sleeves, pants, and closed-toe shoes to protect your skin and feet.

- Hearing protection: Use earplugs or earmuffs when using power tools near the garage.

- Solvent handling: Always use solvents in a well-ventilated area. Never mix different types of solvents.

Quick rule: Safety first, always wear your PPE and follow ventilation guidelines to protect yourself from harm.

Common mistakes to avoid

Learn from others’ errors to save time and money on your project.

- Skipping surface prep: A clean, dry, and profiled surface is crucial for coating adhesion. Neglecting this step leads to peeling and flaking.

- Improper cleaning: Using the wrong cleaner can damage concrete or leave residues that hinder bonding.

- Moisture barriers: Not using a moisture barrier on damp surfaces can trap moisture, leading to delamination.

- Insufficient priming: Priming seals pores and improves coating adhesion. Skipping this step results in poor performance.

- Rushing cure times: Allow coatings to cure undisturbed for the recommended time. Rushing can cause premature failure.

- Neglecting edges: Not protecting edges during curing allows dust and debris to accumulate, compromising the seal.

- Inadequate ventilation: Poor ventilation while applying coatings can lead to improper curing and poor adhesion.

Quick rule: Always follow surface prep guidelines, use appropriate materials, and allow sufficient cure times for best results.

Pre-work planning and site checklist

Before you start any work, ensure your site is ready to prevent delays and rework.

- Moisture test: Check substrate moisture levels. Excessive moisture can hinder bonding and cause delamination.

- Surface prep plan: Have a clear plan for cleaning, profiling, and priming the surface.

- Material ordering: Order all necessary materials in advance to avoid delays during work.

- Cure time scheduling: Plan your schedule around cure times. Allow enough time for coatings to dry undisturbed.

- Notify affected users: Inform neighbors, family members, or other users of the garage about potential disruptions and safety hazards.

- Waste disposal: Arrange for waste removal before starting work. Concrete dust and debris can’t be left on-site.

- Equipment setup: Set up ventilation, tools, and equipment before starting work to ensure everything is functioning properly.

Quick rule: Thorough pre-work planning reduces rework, saves time, and ensures a successful project.

Conclusion

Protecting the edge where the concrete meets the garage matters for safety, looks, and long life. A chipped or compromised edge can spread damage and invite moisture and pests, so a practical plan now saves headaches later.

Review the situation with a simple check: inspect for cracks or spalling, assess moisture and drainage, decide whether you only need patching or a full edge rebuild, prep thoroughly, and test a small area with the chosen coating or armor system before committing to a full application. Then follow the sequence: prep and clean, apply a compatible repair or coating, allow proper curing, and perform regular maintenance checks to catch new issues early.

Common mistakes to avoid include skipping surface prep or using an incompatible coating, rushing a cure, and ignoring drainage or moisture signs. Always test in a small area first, wear PPE, and work in stages so you don’t lock in problems. If you encounter major structural damage, extensive edge loss, or uncertain compatibility of coatings, call in a professional instead of guessing, and move on to a solid, safe solution you can trust.

FAQ

What causes concrete chipping near garage edges, and how can I spot it early?

A lot of chips start where there’s freeze-thaw stress, micro-movement, or steel near the edge vibrating under vehicles. Look for small cracks widening, flaking paint or coatings, and lost edge material at the traffic line. Check the label on any coating or armor product for recommended prep and wear indicators.

How does moisture ingress affect garage floors around the edge, and what should I watch for?

Water gets under the edge through cracks and joints, then expands with temperature changes, pushing chips loose. You’ll see rising damp along the edge, damp spots, or a darker, slick area that worsens after rain. Inspect seals, gutters, and drainage; fix leaks before coatings go on.

How long can floor coatings and armor systems last in high-stress edge areas, and what affects that life?

Durability depends on proper prep, adhesion, and substrate condition. High traffic and vehicle impact shorten life if edges aren’t reinforced. Always follow the product label and manufacturer guidelines, and check for local requirements that may affect longevity.

What simple steps improve safety and slip resistance on coated garage edges?

Use a coating or texture that includes an anti-slip feature suitable for the area. Ensure the surface is clean and dry during application, and test the roughness after cure. If you’re unsure about the finish, ask for guidance on slip resistance ratings from the product instructions.

What maintenance routine should I follow to keep coated edges from failing?

Regularly clean the edge area to remove grit and moisture build-up. Inspect for new cracks, chips, or coating wear after seasonal changes and vehicle use. Recoat or repair only after checking the product’s maintenance schedule and cure requirements on the label.