Introduction

Salt scaling risk on exterior slabs is the tendency for surface flaking and crumbling when moisture is drawn into the top layer and then freezes. This simple field check helps you spot potential damage before winter hits. If you see rough patches or powdery material forming, that can signal trouble.

Signs to watch in the field include tiny flakes, a rough or dusty surface, and cracking along edges or joints. Seasonal shifts—freeze-thaw cycles and the use of salt or de-icers—can push existing weaknesses into visible damage. To reduce risk, clean the surface, follow product labels for de-icing agents, and consider protective maintenance steps recommended for your slab type, and consult a local pro if unsure.

Key takeaways

- Defines salt scaling risk for exterior slabs and why it matters in winter.

- Look for flaking, powdery dusting, or rough edges as early indicators.

- Seasonal freeze-thaw cycles amplify damage; plan preventive actions before temps drop.

- Use broom-clean surfaces and proper de-icing choices to reduce chemical risk.

- Safety warning: wear eye protection and gloves during field checks and tests.

- Preventive coatings and sealers require manufacturer guidance and local code checks.

Table of Contents

- Introduction

- Key takeaways

- What Is Salt Scaling and Why It Matters

- Visual and Tactile Signs of Early Salt Scaling

- Environmental and Usage Factors That Increase Risk

- A Simple Field Salt Scaling Risk Test You Can Do Before Winter

- Tools, Materials Checklist and Testing Alternatives

- Preventive Treatments and Protective Coatings for Exterior Slabs

- Maintenance, Pre-Winter Planning, and Common Mistakes

- Safety, Costs, and When to Hire a Pro

- Conclusion

- FAQ

What Is Salt Scaling and Why It Matters

Salt scaling is a surface condition where the concrete near the top layer shows crystalline deposits, powdering, or a roughened texture after freeze–thaw cycles. It is different from spalling, cracking, or efflorescence in both cause and appearance. Repeated exposure to de-icing salts helps drive the salts to the surface and weakens the outer zone.

Understanding the science in plain terms helps you spot early signs and decide on safe steps. Exterior slabs are more exposed to winter conditions, road salts, and moisture movement than interior slabs. Early detection supports safer use of the slab and can reduce repair costs later on.

How salt causes scaling (mechanism)

The salt from de-icing agents or road salts doesn’t just sit on your slab’s surface. It penetrates and crystallizes within the concrete pores as temperatures drop.

When water freezes, it expands. This expansion force pushes against the concrete from inside out during each freeze-thaw cycle. Over time, this repetitive stress causes the surface to flake and scale off.

The process is like having tiny ice picks chipping away at your slab’s surface with every winter storm.

Materials most vulnerable to salt scaling

Not all slabs are created equal. Some materials and finishes are more susceptible to salt scaling than others.

- Unsealed Concrete: Without a protective seal, salts can easily penetrate and cause damage.

- Broom-Finish: While it provides traction, the textured surface has more nooks and crannies for salt to hide in and cause harm.

- Porous Pavers: These allow moisture and salts to seep in, leading to scaling over time.

- Low PSI Concrete: Lower strength concrete is more prone to damage from freeze-thaw cycles and salt intrusion.

- Improperly Cured Concrete: Inadequate curing leaves the slab porous, allowing salts to penetrate easily.

Visual and Tactile Signs of Early Salt Scaling

Observable signs include faint white or crystalline patches, dull or powdery areas, and slight edge or joint flaking. Hairline cracks or microcracking with a chalky feel can also indicate early salt scaling. Distinguish these from moisture staining, dirt, or typical weathering to avoid false alarms.

On-site checks should be tactile as well as visual. Gently run a gloved finger over the surface to feel for powdery texture. Use a fingernail or putty knife on a noncritical spot to test for roughness or crumbly texture.

Visual checkpoints (what to look for)

Before winter hits, inspect your exterior slabs visually. This checklist helps spot early signs of salt scaling.

- Hairline cracks: Tiny, spiderweb-like lines signal stress. Ignoring them can lead to larger cracks and flaking.

- Faint white or crystalline deposits: These are early signs of efflorescence, a salt byproduct that can cause scaling if left untreated.

- Dull or powdery patches: Loss of gloss or a chalky feel indicates surface deterioration. It’s often too late to prevent flaking at this stage.

- Slight flaking at edges or joints: Small pieces breaking off hint at deeper issues. Delayed action may result in costly repairs.

- Moisture stains vs. salt scaling: Dark spots could be moisture, but if they’re white and crystalline, it’s likely salt-related.

- Dirt or general weathering: Distinguish dirt from scaling by gently brushing the area. If it doesn’t come off easily, it might be scaling.

Quick rule: If you see multiple signs, act fast to prevent worse damage.

Simple tactile checks to perform

Gently touch and probe your slabs to assess their integrity. Wear gloves for safety.

Powdery feel: A light dusting of powder indicates surface deterioration. It’s a clear sign of salt scaling in progress.

Use a fingernail or putty knife to gently scratch a noncritical area. If it feels rough, crumbly, or flakes off easily, the slab is compromised and needs attention.

Tapping: Gently tap the surface with a coin or small hammer. A dull thud instead of a clear sound may indicate delamination, warranting further investigation.

Environmental and Usage Factors That Increase Risk

Climate and seasonal patterns matter because freezing temperatures and repeated thaw cycles move moisture and salts in and out of the surface. They increase the likelihood of salt crystallization at the top where the surface meets the air. Exterior slabs with exposure to winter weather are most at risk.

Drainage and slope affect how long moisture stays near the surface. Pooling water or poor drainage concentrates salts at the interface and sustains freeze–thaw stress. Regular use, traffic, and high exposure areas also concentrate wear and microcracking that start salt scaling.

Climate and moisture drivers

The freeze-thaw cycle is the main culprit behind salt scaling. Here’s how it works:

First, water seeps into concrete pores during mild temperatures. Then, when temps drop below freezing, that water turns to ice and expands, causing tiny cracks. When it thaws again, those cracks can let in more water, setting up a vicious cycle.

Persistent moisture also plays a role. If your slab stays wet for long periods, salts have plenty of time to crystallize and cause damage.

High humidity levels can exacerbate the problem too. The more humid the air, the more water gets drawn into the concrete.

Human factors: salts, traffic, and maintenance

De-icing salts are a double-edged sword. They melt ice, but they also increase the risk of scaling. The more you use, the higher the risk.

Traffic patterns matter too. Heavy foot or vehicle traffic can cause microcracks and edge spalling, creating perfect spots for salt scaling to start.

Maintenance practices can either help or hurt. Regular cleaning can remove salts before they cause damage. But if you’re not careful, repeated immersion-drying cycles can drive chloride ingress and accelerate scaling.

Timing is key here. The more traffic your slab sees, the earlier you should start testing for salt scaling. And the more de-icer you use, the more vigilant you need to be.

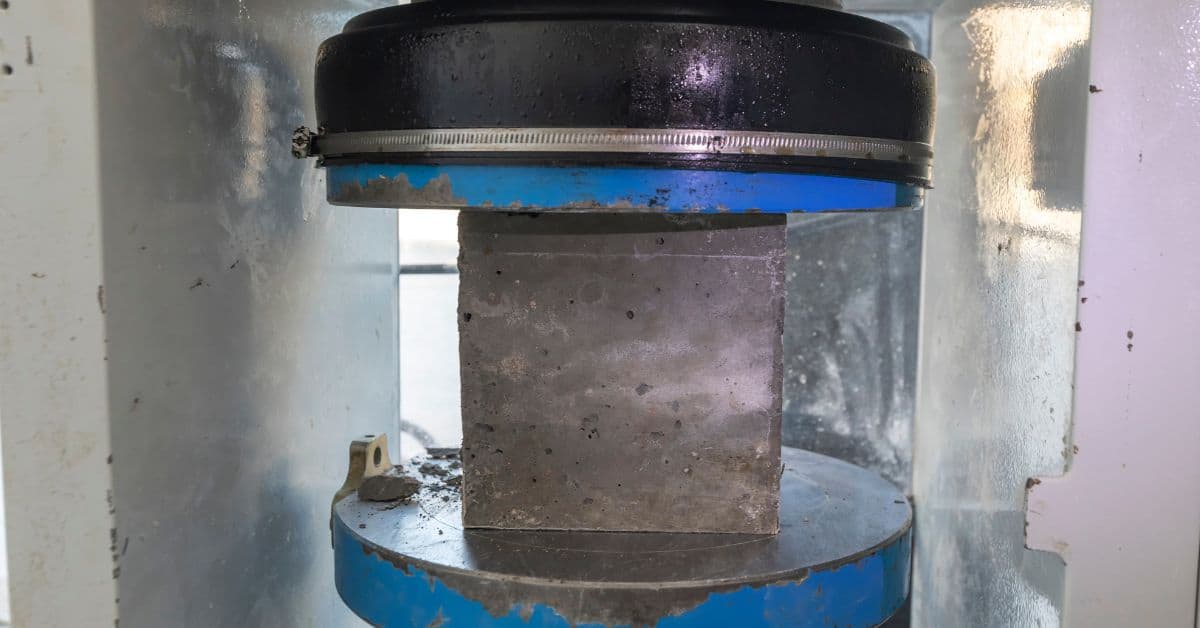

A Simple Field Salt Scaling Risk Test You Can Do Before Winter

The test aims to quick-check surface susceptibility rather than provide a lab-grade assessment. Use it to guide preventive actions and planning. It is not a certification of structural condition.

Safety comes first, and tests should be limited to small surfaces. Follow weather and moisture guidelines to avoid misleading results. Results indicate risk direction, not final condition.

Step-by-step DIY surface assessment

Follow these steps to perform a simple, non-destructive check of your exterior slabs’ susceptibility to salt scaling. This sequence helps you identify potential issues before winter hits.

- Choose 2-3 visually representative spots on the slab for testing. These should be typical areas, not just the worst-looking ones.

- Perform simple tactile checks as mentioned earlier in the article. Feel for any roughness, cracks, or loose pieces.

- Using a spray bottle filled with brine (saltwater mix), apply a controlled amount of solution to each test spot. You’re aiming for a light misting, not heavy saturation.

- Let it dry naturally. Don’t use heat or fans to speed up the process. This could skew your results.

- Inspect the spots after 24 hours. Look for any signs of scaling, such as cracking, powdering, delamination, or spalling. If you see significant damage, consider calling a professional.

Interpreting your field test observations

After performing the test and letting the surface dry, observe the results carefully. The outcome will guide you on the next steps to take.

If there’s no visible change, that’s good news. Your slab is likely less susceptible to salt scaling. However, this doesn’t guarantee it won’t happen, so keep an eye on it and consider retesting in a few years.

If you see a light dusting or powdering, your slab has some susceptibility. This isn’t urgent but warrants attention. Consider applying protective measures like sealers or anti-icing agents.

Rapid flaking or significant damage is a red flag. This indicates a high risk of salt scaling and requires immediate action. Contact a professional for further assessment and repairs as soon as possible.

Tools, Materials Checklist and Testing Alternatives

Prepare a concise on-site kit with portable tools, basic test items, and common concrete accessories. Include ways to pair field checks with a basic lab option if needed. Keep the kit compact and weather-ready for winter work.

Split duties into on-site and optional remote testing paths, with substitutions if some tools are unavailable. Prioritize portability, simple calibration, and quick documentation steps for winter conditions.

On-site checklist and protective gear

Before you start, ensure you have the right tools and safety gear to protect yourself and your concrete. Here’s a practical on-site checklist.

- Work gloves: Protect your hands from sharp edges and cold temperatures.

- Scraper or chisel: To remove any debris or dirt from the surface.

- Hammer: For tapping to check for hollow spots (delamination).

- Moisture meter: To measure slab moisture content. Ideal range: 4-6%.

- Camera: To document your findings and record data.

- Safety glasses: Protect your eyes from debris and falling objects.

- Ear protection: If using power tools, protect your hearing.

- Knee pads: For comfort during extended periods of kneeling or crawling.

- Protective clothing: Dress in layers to adapt to changing temperatures and weather conditions.

Quick rule: Always check product labels for proper disposal of removed materials, and follow local waste management rules.

When to use a portable kit or lab analysis

For more accurate results, consider using a portable test kit or sending samples to a lab. Here’s when and why you might choose one over the other.

- Portable chloride/salt spot kits: Quick and easy to use on-site. Ideal for initial screening and follow-up checks.

- Lab analysis (ASTM/Canadian standards): Provides more accurate, detailed results but takes longer. Recommended for high-risk situations or when initial tests are inconclusive.

- Turnaround time: Portable kits: immediate; Lab tests: 3-7 business days.

- Cost range: Portable kits: $20-$50; Lab tests: $50-$150 per sample.

Quick rule: Always confirm the test kit’s standards and certifications before purchasing to ensure accurate results.

Preventive Treatments and Protective Coatings for Exterior Slabs

Protection falls into three broad categories: penetrating sealers, film-forming sealants, and surface hardeners. Each type has practical uses based on the slab’s condition and exposure. Choose the option that best aligns with performance goals and maintenance plans.

Understand how and when to apply each type, including prep steps and compatibility checks. Consider how breathability, wear resistance, and surface appearance influence your choice for exterior slabs.

Choosing the right sealer or coating

The first step to protecting your exterior slabs is choosing the right product. Here’s what you need to consider:

Porosity: High porosity slabs need deep penetration. Penetrating sealers are ideal here.

Exposure: Slabs exposed to heavy traffic or harsh weather conditions need robust protection. Film-forming sealants and surface hardeners can provide this.

Drainage: Good drainage helps prevent water buildup. Make sure your chosen product won’t trap moisture.

Always check manufacturer specifications for compatibility with previous treatments and ensure they match your slab’s needs.

DIY application tips for better results

Applying sealers correctly is crucial for their performance. Here are some tips:

Surface Prep: Clean and prepare the surface thoroughly to ensure good adhesion.

Ideal Conditions: Apply in dry, mild conditions (50-90°F or 10-32°C) for best results. Avoid applying when rain is expected within 24 hours.

Avoid Common Mistakes: Don’t apply too thickly, as this can trap moisture and cause damage. Also, avoid over-applying in areas with heavy traffic to prevent premature wear.

Always follow the manufacturer’s instructions for specific application details.

Maintenance, Pre-Winter Planning, and Common Mistakes

A pre-winter inspection should focus on cracks, moisture issues, and drainage. Prioritize fixes that prevent water intrusion and salt ingress before cold weather arrives. Develop a simple sequencing plan for repairs and treatments.

Keep debris clear, dry the surface, and choose compatible products. Document slab age, coatings, and prior maintenance to build a useful comparison record for next season.

Pre-winter timeline and priorities

Before winter hits, follow this sequence of actions to protect your exterior slabs:

Inspect first. Look for cracks, spalling, moisture intrusion, and drainage issues. These need fixing before temperatures drop. Prioritize repairs based on severity and location.

Clean next. Remove debris, use a non-residue cleaner, and let it dry. Don’t pressure wash treated or delicate surfaces aggressively.

Seal last. Choose the right treatment based on your slab’s condition (see below). Some sealers need curing time before freeze season. If you find major damage or structural issues, consult a pro before winter.

Common mistakes and how to avoid them

Here are some common missteps that accelerate scaling or negate treatments:

- Sealing over active damage. This traps moisture, leading to further deterioration. Always repair cracks and spalls before sealing.

- Using the wrong salt. Some de-icers can damage concrete. Stick with low-salt or alternative products where possible.

- Skipping drainage fixes. Standing water accelerates scaling. Improve slope and drainage to prevent this.

- Over-applying treatments. Too much sealer can trap moisture, causing more harm than good. Follow product instructions carefully.

- Inadequate maintenance intervals. Regular cleaning and re-sealing are crucial. Don’t wait until your slab shows signs of distress.

By avoiding these mistakes, you’ll extend the life of your exterior slabs and keep them looking good year-round.

Safety, Costs, and When to Hire a Pro

Follow safety protocols for tests and treatments, including eye protection, gloves, and appropriate footwear. Plan around winter hazards and the potential for slippery surfaces. Protect yourself and others during fieldwork.

Cost considerations include materials, equipment, and labor, with different drivers for prevention versus repair. Recognize scenarios that benefit from professional evaluation, such as unusual cracking or extensive scaling.

Safety considerations and waste handling

Always prioritize safety when working on your exterior slabs. Here’s what you need to consider:

Personal Protective Equipment (PPE): Wear appropriate gear like eye/face protection, gloves, and a respirator for dust control.

Chemical Safety: Be cautious with de-icers and sealers. Follow manufacturer instructions, use in well-ventilated areas, and avoid contact with skin or eyes.

Waste Handling: Contain and dispose of removed material responsibly. Check local regulations for concrete waste disposal.

Budgeting, cost factors, and choosing a contractor

Understanding the costs involved is crucial before starting any work. Here are some key factors to consider:

Surface Area: Larger slabs mean more material and labor costs.

Repair Extent: Minor repairs will cost less than major ones.

Product Choice: Premium products may increase upfront costs but could extend lifespan, saving you money in the long run.

Choosing a Contractor: Get multiple quotes. Select an experienced concrete contractor based on their reputation, licensing, insurance, and past work quality.

Conclusion

Protecting exterior slabs from salt scaling comes down to quick checks, careful testing, and timely treatment before winter hits. A solid plan saves you from costly repairs and keeps the surface looking and behaving right when cold, wet conditions arrive.

First, check small, inconspicuous patches for flaking, roughness, or powdery texture, then run a simple field risk test in a single low-traffic area following the basic steps described earlier, record the results, and apply preventive measures only after confirming the test area is representative. Inspect the environment, traffic, and prior coatings, then choose a durable treatment or coating and follow label directions exactly, starting with the least aggressive option.

Avoid these common mistakes: skipping the small-area test before moving to larger sections, overrelying on a single product or shortcut, and neglecting safety gear or weather windows. Always wear appropriate eye protection and gloves, work in daylight or good visibility, and never mix cleaners or cleaners with any coating unless the manufacturer allows it. If the risk is high, if you see advanced scaling, or if you lack the tools or time to do correct prep, call a pro rather than pushing ahead.

If in doubt about the right coating, the correct maintenance schedule, or your climate’s specific risks, a pro can help tailor a plan. Stay methodical, stay safe, and you’ll keep the slabs durable and winter-ready without guesswork or regret.

FAQ

What exactly is salt scaling risk for exterior slabs?

Salt scaling risk is the likelihood that the surface of your concrete will crack, spall, or shed a thin layer when winter salts are used. It happens when the mix, condition, or protection can’t resist freeze-thaw cycles combined with salt exposure.

Think of it as a marker for how vulnerable your slab is to salt-related damage over time. You’re looking for signs that the surface may fail or roughen under typical winter use.

What signs in field conditions point to potential salt scaling risk?

Look for a chalky or powdery surface, flaking edges, or tiny popping sounds when you walk on the slab. If the top layer feels rough or crumbles under a stiff brush, that’s a warning.

Moisture from rain, irrigation, or melting snow that sticks to the surface without drying can amplify the risk. Repeated freeze-thaw cycles with salt exposure often speeds up these clues.

How does the winter season affect durability, and what maintenance helps?

Winter heat cycles plus salt use stress the surface. The more cycles you face, the higher the chance of surface damage showing up on the slab.

Keep drainage clear, remove standing water, and scrub away any chipped or loose material before applying any preventive coating. If you see signs of scaling, address them before heavy freezing hits in earnest.

What preventive measures and upkeep should I plan for?

Seal or treat the slab with a coating that suits exterior exposure and traffic. Choose products with clear manufacturer instructions and verify they’re compatible with salt exposure in your area.

Limit salt use when possible, use non-salt de-icers where practical, and re-apply protective coatings per the label timing. Regularly inspect for early signs of wear and re-coat as needed after resurfacing is required.