Introduction

A patch for a concrete slab edge with a return form is a method to rebuild the edge so it doesn’t chip again. It’s a hands-on repair that focuses on shaping the edge and sealing it with materials suited for your concrete. You’ll want to assess the chipped edge, pick appropriate repair materials, and set up a return form before pouring.

Identify edge chipping by looking for exposed rebar, flaking, or missing concrete along the edge. Prepare the damaged area by cleaning, roughening the surface, and removing loose material, then set up a return form to recreate the edge profile. Choose materials you can work with that match the existing slab, and always check product labels and manufacturer instructions for cure times and safety notes.

Key takeaways

- Identify edge chipping early by inspecting edge with a light tap and feel.

- Prepare edge by cleaning dust, loose concrete, and surface laitance before patching.

- Use a return form to create a crisp edge and prevent future spalling.

- Choose repair materials compatible with existing concrete and climate exposure.

- Wear eye protection and gloves; set up forms securely to avoid releases.

- Build and secure the form firmly to maintain edge integrity during cure.

Table of Contents

- Introduction

- Key takeaways

- Quick Overview: What a ‘Return’ Form Is and Why It Prevents Chipping

- Planning and Preparation Before You Begin

- Tools and Materials Checklist

- Material Choices and Specs Explained

- Designing and Building the Return Form

- Step-by-Step Repair Process with the Return Form

- Finishing, Curing, and Visual Quality Checkpoints

- Safety, Cost Estimation, and Common Mistakes to Avoid

- Conclusion

- FAQ

Quick Overview: What a ‘Return’ Form Is and Why It Prevents Chipping

A return form is a repair option that recreates a true edge profile on a damaged slab. It typically features a short vertical lip plus a recessed edge that mirrors the existing edge rather than a flat cut. This setup differs from standard flat-edge forms and helps resist future chipping by defining a robust perimeter.

Mechanically, the vertical leg redirects bending stress away from the outer lip, and the undercut with a re-entrant corner reduces stress concentration. A continuous edge profile improves durability over time. This method is best when the edge is repairable but chipped, the slab thickness and load allow it, and you have access to proper forms. Consider other fixes if the edge damage is extensive or conditions favor a simpler patch.

What a ‘return’ form does

A ‘return’ form rebuilds your concrete slab’s edge profile. It extends new concrete around the edge, creating a robust, interlocked profile.

The form has a short vertical lip and a recessed edge. This geometry mirrors the existing slab edge, supporting a stronger, chip-resistant perimeter.

Think of it like this: standard forms create flat edges that can easily chip off. Return forms give you an edge with built-in strength and durability.

When to use a return form vs a surface patch or epoxy

Return forms are best when your slab’s edge is damaged but repairable. Here’s when:

Undermining: If the edge crumbles easily, it might be undermined. A return form rebuilds the entire edge.

Recurring chips: If the edge keeps chipping despite repairs, a return form can help prevent future damage.

Traffic loads: High traffic areas need robust edges. Return forms can handle heavy use better than surface patches or epoxy.

Benefits and limitations

Durability: Return forms create a strong, long-lasting edge that resists chipping and cracking.

Labor-intensive: While DIY-friendly, return form repairs take more time and effort than simple surface patches or epoxy applications.

Professional work may be preferable: For large slabs, complex edges, or when you’re unsure about the damage extent, consider hiring a pro.

Return forms aren’t perfect. They require proper setup, materials, and curing to avoid early chipping. But done right, they give you a durable edge that lasts.

Planning and Preparation Before You Begin

Start with an inspection checklist to assess chip extent, substrate soundness, and any moisture issues that could affect adhesion. Look for efflorescence or contaminants that should be cleaned before patching.

Measure and mark the area carefully to align the return form and ensure the patch sits flush with surrounding concrete. Plan safe access, staging space, dust control, and the sequence of steps to minimize rework. Check weather and curing windows and verify the patch material and bonding agents are compatible with the existing slab.

Inspecting damage and substrate

Before you start, inspect the damaged area thoroughly. You’re checking for:

Undermining: Any signs of crumbling or hollow-sounding concrete beneath the chip.

Rebar exposure: Exposed reinforcement bars could rust and cause further damage if not addressed.

Moisture and efflorescence: These can affect patch adhesion. If present, consider waterproofing or addressing the source of moisture.

Measuring, marking, and scope of work

Accurate measurement is key to a successful repair. Here’s how:

Measure the length of the damaged area. Decide how much concrete to remove based on damage extent and your return form size.

Mark cut lines using a straight edge and a marker or chalk. These will guide your saw cuts for the new edge profile.

Also, mark alignment points for your return form. This ensures the patch sits flush with surrounding concrete.

Scheduling, permits, and environmental considerations

Timing is crucial for a good repair:

Avoid working in extreme temperatures or when precipitation is forecasted. Ideal curing temps are 50-90°F (10-32°C).

Check local rules and homeowners association requirements for any necessary permits or restrictions.

Consider environmental factors too: protect nearby plants from concrete dust, and dispose of waste responsibly.

Tools and Materials Checklist

List the hand tools you’ll use for edge work or form setup in the space you’re working in, including a measure, level, straightedge, and marking tools. Have area-specific items ready for edge repair or form setup indoors, outdoors, or in a garage.

Prepare power tools and mixing equipment, plus the fasteners and form materials needed for the return edge. Include appropriate patch mix, bonding agents, release agents, and a plan for clean-up and reuse of forms as applicable.

Essential tools

Before you start, ensure you have all the necessary tools to prep, mix, and apply your concrete patch.

- Grinder: To smooth out rough edges. Skipping this can lead to an uneven finish.

- Chisel & Hammer: For removing loose concrete and creating a clean edge.

- Trowel: To spread and level the patch mix.

- Level & Straightedge: To ensure your form is square and your patch is even.

- Clamps: To secure your form in place. Without them, your form may shift during pouring.

- Mixing vessel or mixer: To combine your concrete mix. Using an unsuitable container can lead to improper mixing and weak patch.

- Tape measure: To accurately mark and cut your form materials.

- Pry bar: To help remove any stubborn chunks of damaged concrete.

Quick rule: Always inspect tools before starting to ensure they’re in good working condition. A faulty tool can cause more harm than good.

Materials and consumables

Gather all necessary materials before you begin your patching project to avoid delays.

- Concrete mix: Choose a fast-setting, high-strength mix for patching. Using the wrong mix can result in a weak or slow-curing patch.

- Bond coat: To improve adhesion between your old concrete and new patch. Skipping this can cause your patch to peel off.

- Form materials (lumber, panels, plywood): Measure and cut these to create your return form. Inadequate form material can lead to a poorly shaped patch.

- Fasteners (concrete screws, masonry anchors): To secure your form in place. Without proper fasteners, your form may shift during pouring.

- Adhesive or release agent: To prevent the concrete from sticking to your form. Not using this can make removing the form difficult.

- Sealant: To apply after curing to protect your patch from moisture and weathering. Skipping this can shorten your patch’s lifespan.

- Curing product: To help your patch cure properly. Neglecting this step can result in a weak, brittle patch.

Quick rule: Always check the expiration dates on materials before use to ensure they’re still viable.

Personal protective equipment

Safety should always be your top priority. Ensure you have all necessary PPE before starting any concrete work.

- Eye/face protection: Safety glasses or goggles to protect from debris and splashes. Without this, you risk eye injuries.

- Gloves: To protect your hands from cuts, burns, and chemicals. Working without gloves can lead to hand injuries.

- Respirator or dust mask: To protect from concrete dust. Inhaling this dust can cause serious health issues.

- Hearing protection: To safeguard your hearing from loud tools and equipment. Prolonged exposure to noise can lead to hearing loss.

- Knee pads: For comfort and protection when kneeling on hard surfaces. Without knee pads, you may experience discomfort or injury.

- Proper clothing: Wear long sleeves, long pants, and sturdy boots for full-body protection. Inadequate clothing can lead to injuries from falling debris or hot materials.

Quick rule: Always inspect your PPE before use to ensure it’s in good condition and provides adequate protection.

Material Choices and Specs Explained

Identify when hydraulic cement versus polymer-modified mortars is appropriate. Hydraulic cement can give quick set and water resistance for small chips, while polymer-modified mortars improve bonding on slightly damp or dusty substrates.

Consider fast-setting patch mixes for time-sensitive repairs at the return edge, and understand their open time and cure considerations. Use bonding agents and primers only as needed and verify compatibility with the chosen patch. Emphasize proper surface prep and substrate conditioning to improve key and long-term durability.

Choosing the right patch material

The patch material you choose can make or break your repair job. Each has its strengths and weaknesses.

- Hydraulic Cement: Quick-setting, water-resistant. Ideal for small chips with no dampness. Avoid for deep voids or damp surfaces.

- Polymer-Modified Mortars: Better bonding, tensile strength. Works on slightly damp or dusty substrates. Not suitable for full-depth voids.

- Fast-Setting Patch Mixes: Time-sensitive repairs. Open time and workable pot life vary. Color and texture may mismatch existing concrete.

- Bonding Agents: Enhances adhesion on smooth or sealed edges. Compatible with hydraulic cement and polymer mortars. Test for adhesion before applying patch.

Bonding agents and admixtures

Bonding agents, epoxy primers, or admixtures can improve your patch’s bond to the substrate. But use them wisely.

Use a bonding agent: On smooth or sealed edges where mechanical key is minimal. Follow product compatibility guidance.

Avoid using an admixture: Unless recommended by the patch material manufacturer. Incorrect use can weaken the bond.

Always perform a simple adhesion test (scratch test or light tug) before applying the patch to ensure the bonding agent works as expected.

Form materials and durability

The form material you choose affects your repair’s longevity and ease of application.

- Plywood: Inexpensive, easy to use. Not suitable for reuse due to water absorption. Seal edges to prevent leakage.

- Plastic: Lightweight, flexible. Ideal for reuse but may not provide a flat surface for large repairs. Seal seams with tape.

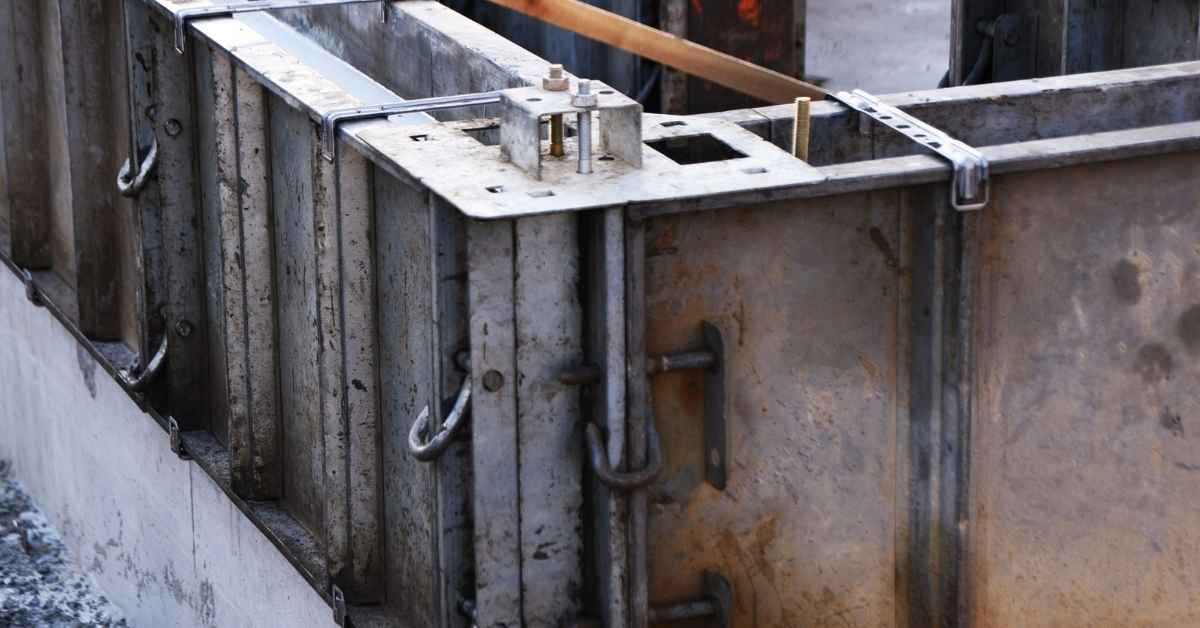

- Metal: Stiff, durable. Expensive and heavy. Requires proper sealing to prevent rusting and leakage.

Designing and Building the Return Form

Decide the return form profile and dimensions to match the existing slab and improve chip resistance, including standard versus oversized returns. Plan how the edge will project and what finish is required for a straight, true face.

Outline anchoring and temporary support methods to keep the form plumb and leak-free during pour and cure. Choose materials that yield a clean, reusable face, and think about release agents and corner bracing to minimize surface defects. Address tolerances, alignment, and waterproofing to prevent sticking or misalignment after removal.

Form profile and dimensions

The return form’s profile should mimic the existing slab’s edge to create a seamless repair. Plan for a consistent face thickness, typically matching your slab’s thickness minus 1/4 inch for a slight recess.

Consider an oversized return (e.g., 2-3 inches wide) for added chip resistance. A smooth radius or bevel at the form’s edge helps prevent stress cracks and provides a clean finish.

To ensure a smooth connection, align the form with the existing slab’s edge using a straightedge and level. Mark the form’s height to match the slab’s thickness, then use a jigsaw or circular saw to cut it precisely.

Fastening, sealing, and leak control

Secure forms with stakes driven into the ground every 16-24 inches. Use a level to ensure they’re plumb. Attach the form to the stakes using screws or nails, keeping it tight against the existing slab.

Seal joints between form pieces and the existing slab with a bed of release agent or a bead of sealant to prevent slurry loss and sticking. Apply generously, but avoid over-applying as excess can cause defects.

Brace forms against pressure during placement using 2x4s or adjustable braces. Attach them at an angle between the form and the ground or existing slab. This keeps the form rigid and prevents it from shifting under concrete’s weight.

Templates, jigs, and reusable form pieces

For repeatable edge repairs, consider making templates or reusable form inserts. This saves time and ensures consistent results.

- Measure twice: Ensure your measurements are accurate to create a precise template.

- Use sturdy material: Plywood or composite panels work well for templates. Thicker materials (1/2 inch or more) provide better stability.

- Include alignment marks: Add clear, visible marks on the template to ensure it’s positioned correctly each time.

- Test fit: Before using your template, test-fit it against the existing slab to confirm it’s the right size and shape.

- Avoid warping: Store templates flat or supported to prevent warping, which can lead to inaccurate forms.

- Label clearly: Label each template with its intended use (e.g., ‘Front yard slab – West edge’) for easy identification.

- Regular maintenance: Inspect and maintain templates regularly. Repair or replace as needed to keep them in good working order.

- Keep records: Document your template’s dimensions, intended use, and any specific notes to help future repairs go smoothly.

Quick rule: If you’re repairing multiple edges with the same profile, investing time in creating reusable templates can pay off significantly in efficiency and consistency.

Step-by-Step Repair Process with the Return Form

Begin by removing all loose or damaged concrete from the edge and cleaning dust and debris. Neutralize any oils or curing compounds that might hinder adhesion.

Inspect the substrate for moisture and reinforcement, and address any moisture or freeze-thaw concerns before setting the form. Install and secure the return form precisely to the edge, using guides, stakes, and fasteners to prevent movement during pouring.

Step-by-Step Repair Process

This sequence will guide you through repairing a concrete surface, ensuring safety and durability.

- Preparation: Clear the area of debris. Inspect the damage for signs of structural issues or rebar exposure. If unsure, consult a professional before proceeding.

- Safety Checks: Wear appropriate safety gear (gloves, goggles). Ensure no live electrical wires are nearby. Check local rules if you’re working near gas lines.

- Surface Preparation: Clean the area thoroughly using a wire brush or pressure washer. Let it dry completely to ensure proper bonding of repair materials.

- Mixing Concrete: Follow manufacturer’s instructions for mixing concrete. Aim for a consistency like thick oatmeal. Check by dropping a handful onto the surface; it should spread slightly but hold its shape.

- Applying Repair Material: Trowel or shovel the mixed concrete into the damaged area, pressing firmly to remove air pockets. Ensure the repair is level with the surrounding surface. Use a straight edge to check and adjust if necessary.

- Finishing Touches: Smooth the repaired area using a trowel or float, ensuring it blends seamlessly with the existing surface. Allow excess water to evaporate but avoid letting the repair dry out too quickly.

- Curing: Cover the repaired area with plastic sheeting to retain moisture and speed curing. Check local climate conditions; in hot, dry areas, you may need to mist the repair daily. Wait at least 72 hours before walking on or applying heavy loads.

- Final Checks: After the waiting period, gently test the repaired area with light foot traffic or a light load. Inspect for any signs of cracking or weakness. If all looks good, proceed with normal use.

Pro tip: Always follow manufacturer’s instructions when using repair materials to ensure optimal results and longevity.

Surface preparation and cleaning

First things first, you gotta get that surface ready for the new concrete. Start by removing any loose bits with a chisel or wire brush.

Roughen it up – You want the new concrete to stick like glue, so use a diamond blade on your angle grinder to roughen the substrate. Be careful, mate, safety first!

Now, grab a broom and sweep away any dust or contaminants. A clean surface is key here.

Some repair products might need you to pre-wet the surface before applying. Check your product label or manufacturer’s instructions for that. It’s usually around 15-30 minutes before application, but better safe than sorry.

Mixing and placing the patch material

The right materials ensure a durable, long-lasting repair. Here’s what you need:

- Concrete Repair Mortar: Look for Type N or Type S mortar. These have high bond strength and are suitable for most repairs. Check the bag for ‘Conforms to ASTM C476’ for quality assurance.

- Polymer-Modified Concrete Repair Materials: For larger cracks or areas with heavy traffic, consider polymer-modified materials. They’re more expensive but offer better durability and flexibility. Look for ‘Polymer Modified’ on the label.

- Epoxy Injection Resin: For hairline cracks (less than 1/8″), epoxy injection is ideal. It’s strong, durable, and waterproof. Follow manufacturer instructions for mixing ratios.

- Concrete Repair Grout: For small voids or honeycombing, use a sanded grout. Check the label for ‘Sanded’ and ensure it matches your concrete’s strength class (e.g., C20, C30).

- Clean Water: Use clean, potable water for mixing. Don’t skimp on quality here; it affects the final product.

Cheap, generic ‘concrete mix’ won’t cut it. It’s weak and prone to cracking. Safety-wise, improper materials can lead to slippery surfaces or structural issues down the line.

Pro tip: Buy only what you need. Concrete repair materials have a limited shelf life once opened. Store unused portions in airtight containers away from extreme temperatures. When mixing, follow manufacturer instructions closely for consistent results.

Installing the return and initial finishing

Now that you’ve prepped your surface and mixed your patch material, it’s time to form the return and install the patch. Remember, timing is crucial here – check your mix’s set time on the product label.

First, secure your form properly. Ensure it’s level and plumb using a spirit level or laser level. The return should match the existing concrete profile for a seamless repair. Check base compaction before you start – it needs to be solid.

Next, strike off your patch material to the correct profile. Use a magnesium float or a straight edge to ensure a smooth, level surface. Work quickly but carefully – you don’t want to disturb the base or leave marks on the fresh concrete.

Once struck off, use a broom finish tool to create a textured surface that matches your existing concrete. This helps hide any minor imperfections and gives your patch a natural look. Remember, less is more here – don’t overdo it and create a rough surface.

Finishing, Curing, and Visual Quality Checkpoints

Finish the patch to match the existing texture, using the appropriate trowel or texture tool and feathering the edge to blend in. Ensure the return form edge remains snug without high ridges or indentations.

Discuss color-matching options and perform a quick test patch to verify hue and sheen before full application. Cover curing methods and moisture management, and plan for protection during early use to prevent chipping. Include simple bond checks and visual cues to confirm a solid, durable edge.

Tooling and texture matching

Once the patch has set, use this checklist to match its texture and tooling to the existing slab.

- Broom finish: Use a broom with stiff bristles. Sweep in one direction for consistent lines.

- Trowel marks: Use a steel trowel to create fine grooves, matching the existing slab’s pattern.

- Screed lines: Use a straight edge to create clean, sharp lines.

- Light tooling: For smooth surfaces, use a float or magnesium float for light finishing.

- Aggressive finishing: For rough textures, use a wood float or steel brush for heavy brooming.

- Feathering: Use a soft-bristle brush to feather the patch edge into the surrounding surface.

- Avoid high ridges: Ensure the return form edge is snug but not creating high ridges.

- Avoid indentations: Check for any low spots or indentations that could collect water.

Quick rule: Always match the existing slab’s texture and tooling to maintain a uniform appearance.

Curing methods and timelines

After texturing, use this checklist to cure the patch properly.

- Wet curing: Mist the surface with water regularly. Avoid over-saturating.

- Plastic sheeting: Cover the patch with plastic to retain moisture. Ensure it’s secure but not too tight.

- Curing compound: Apply according to package instructions. Use a sprayer or roller for even application.

- Duration (70°F/21°C): Cure for at least 3 days, keeping the surface moist but not wet.

- Duration (60°F/15°C): Cure for up to 7 days. Monitor closely for signs of drying out.

- Avoid rapid loss: Prevent quick moisture loss by maintaining consistent temperature and humidity.

- Follow directions: Always follow product instructions for specific curing times and conditions.

Quick rule: Proper curing prevents hairline cracks and ensures a strong bond.

Final inspection and performance tests

Before using the patched area, perform these simple checks to ensure a solid repair.

- Adhesion: Gently tap the patch with a hammer. No dull thuds indicate weak bond.

- Hairline shrinkage: Look for any fine cracks around the edges or within the patch.

- Alignment: Check that the patch is level and aligned with the existing slab.

- Uniform texture: Ensure the patch has a consistent appearance, matching the surrounding surface.

- No reveals: Check for any gaps or spaces between the patch and the existing slab.

- No hollow spots: Tap the patch. A dull sound indicates a weak spot or honeycombing.

- Edge integrity: Gently flex the edge of the patch. No movement indicates a strong bond.

- Settlement: Check for any signs of settling, such as dips or unevenness.

Quick rule: Thorough inspection ensures a durable, long-lasting repair.

Safety, Cost Estimation, and Common Mistakes to Avoid

Follow safety protocols, including PPE and ventilation when mixing or handling bonding agents. Lock out nearby utilities and manage trip hazards on the jobsite.

Prepare the edge surface and environment, verify patch material selection, and mix in small batches to avoid stiffening. When estimating material and labor, note the need for forms, patch mix, bonding agents, curing blankets, and a contingency without quoting exact prices. Learn from common mistakes such as skipping surface prep, misalignment, incorrect curing, or failing to seal after repair.

Safety precautions and jobsite controls

Wear gloves, eye protection, and a respirator if sanding. Keep bystanders away from wet patches. Use proper lifting technique for heavy materials.

Control dust with wet cutting or vacuuming. Ensure safe tool operation. Ventilate when mixing concrete or using bonding agents.

Lock out nearby utilities to prevent accidents. Be aware of trip hazards and keep the area clean.

How to estimate materials, labor, and time

The right patch material affects your result. Estimate based on linear edge length and average thickness.

- Patch volume: Linear edge length × Average thickness

- Form material: Consider form size, number of uses, and cost per use

- Patch mix: Choose a suitable patch compound for your slab’s concrete type

- Bonding agents: Look for ones compatible with your slab’s surface. Apply according to manufacturer’s instructions

- Curing blankets/sealants: Consider cost and application method

- Labor time: Build a 10-20% contingency into your estimate

Common mistakes and troubleshooting

Avoid these common errors for successful repairs.

- Insufficient prep: Skipping cleaning or removing loose chips weakens adhesion. Always clean, dry, and assess moisture risks

- Poor form sealing: Leakage causes uneven edges. Ensure forms are properly sealed before use

- Wrong material choice: Using incompatible materials leads to cracking or staining. Match your slab’s concrete type for best results

- Inadequate curing: Improper curing causes weak bonds and cracking. Follow manufacturer’s guidelines for optimal cure times

Regularly inspect your work, learn from mistakes, and adjust your approach as needed.

Conclusion

The core aim is a patch that locks the edge in place, looks right, and stays intact. A properly built return form creates a strong, chip-resistant edge that keeps water and traffic from gnawing into the slab.

Finish the job by following a simple, practical flow: verify you have the right tools and materials, set and brace the return form accurately, mix and apply the repair material cleanly, smooth and feather the edge, and then cure and inspect the result. Check the edge for a solid bond, test small sections for adhesion, and wait for the proper cure before exposing it to use or moisture.

Common mistakes to avoid are skipping the cure time, rushing the spacing and alignment, and skimping on edge preparation or form bracing. Always wear eye protection and gloves, work in a dry, clean area, and test a small patch first to confirm adhesion and cure. If the edge still chips or you’re unsure about the slope, don’t force it—pro advice can save you time and money in the long run.

If the slab carries heavy loads, or if the edge is badly degraded or structurally suspect, consider bringing in a pro rather than pushing ahead alone. With careful planning and steady execution, you’ll finish with a durable, clean edge you can trust for years to come.

FAQ

How can I tell if the edge is actually chipped or just rough from wear?

Look for a sharp edge with a visible gap or spall along the edge. If the edge looks rounded or flakes off easily when you press, it’s chipping. If in doubt, poke with a small tool and note how the surface responds.

What materials work best for patching a concrete edge that will receive a return form?

Choose a patch compound or repair mortar that wets well to the existing edge and cures solid. Check the product label for compatibility with concrete and for surface prep needs. If unsure, compare options and follow the manufacturer instructions closely.

How do I prep the damaged edge before forming the return?

Clean out loose material and dust from the edge. Rinse or dampen the area lightly so it’s not powdery, then roughen the surface to help bond. Remove any debris and let it dry to a workable tack before applying repair material.

What’s the key to shaping a return form and getting a clean finish?

Build the return form snug to the edge with no gaps. Use barriers or forms that hold the patch flush with the surrounding slab. After patching, remove the form as instructed and finish the edge promptly to blend the surface. If unsure, follow the form manufacturer’s guidance and test on a small area first.