Introduction

A concrete joint sealant that won’t track dirt is a smooth, well-profiled sealant that stays put and is easy to wipe clean.

The profile shape you choose affects how debris collects and how easy cleanup is. This intro covers practical, hands-on steps to plan and apply a dirt-resistant joint.

Choose a profile that minimizes crevices where dirt can settle, and keep tools clean during cleanup. For cleanup, wipe the joint while the sealant is cure-friendly; avoid harsh solvents unless approved by the product label. If you’re unsure about what to use or how long to wait, check manufacturer instructions and local rules for your area.

Key takeaways

- Understand sealant choice affects dirt tracking and joint movement in concrete.

- Profile shapes with rounded or beveled edges resist dirt adhesion during service.

- Surface treatments and compatible sealants reduce dirt pickup on joints.

- Follow installation and curing practices to minimize future staining and washout risks.

- Regular cleaning using proper methods extends joint life and maintains appearance.

- RCP compatibility notes: verify sealant/joint specs suit exposed pipe installations.

- Safety: wear PPE, work in ventilated areas, and follow manufacturer guidelines.

Table of Contents

- Introduction

- Key takeaways

- What a Concrete Joint Sealant Is and Why Dirt Tracks

- Profile Shapes That Reduce Dirt Tracking

- Sealant Materials and Surface Properties That Resist Dirt Adhesion

- Installation Best Practices to Minimize Future Dirt Tracking

- Cleaning and Maintenance Methods for Sealed Joints

- Compatibility with Reinforced Concrete Pipe (RCP) and Other Structures

- Costs, Longevity, Safety, and Environmental Factors

- Common Mistakes, Troubleshooting, and Visual Checkpoints

- Conclusion

- FAQ

What a Concrete Joint Sealant Is and Why Dirt Tracks

A concrete joint sealant is meant to seal expansion and control joints to keep water, dirt, and moisture from sneaking into the joint space while still allowing movement as the slab expands or contracts. The surface design choices you make influence how well dirt is kept out and how easy cleaning will be over time. Check manufacturer instructions or product labels to confirm movement capacity and surface compatibility before you decide on a profile.

Typical joint movement includes compression, extension, and shear, and these movements dictate profile geometry and material selection. Surface profiles with angled lips or sculpted shoulders can affect dirt capture and shedding under foot traffic, wind, and splash. When you compare straight, chamfered, or concave/convex profiles, weigh how each trades dirt shedding for sealant performance and how easy it will be to clean later. Tie maintenance to the profile by considering solid-cleanable surfaces, debris avoidance, and what cleaners work with the chosen sealant; plan routine inspections and quick-release cleaning methods to avoid damaging the sealant.

Sealant function and common contexts

A concrete joint sealant’s primary job is to keep water, dirt, and moisture out of your joints. It does this by sealing expansion and control joints.

You’ll find these sealants in various places around your home – expansion joints (like those in driveways or sidewalks), control joints (in slabs like patios or pool decks), and even in large concrete pipes (RCP).

The goal is always the same: prevent water intrusion while allowing for timely joint movement. This means the sealant needs to be flexible enough to accommodate static, short-term, and long-term movements.

How dirt tracking occurs

Dirt tracking happens when particles stick to your sealant’s surface. This can be due to the sealant’s softness or adhesiveness, especially under foot traffic.

Wind and splash conditions can also drive dirt into the sealant’s profile. The shape of the profile – whether it’s straight, chamfered, concave, convex, microtextured, or smooth – affects how much dirt gets trapped.

Capillary action might also pull moisture and dirt into the sealant’s pores. This is why proper cleaning and maintenance are crucial to prevent dirt buildup.

Profile Shapes That Reduce Dirt Tracking

Profile shapes include recessed or concave, convex, angled, double-bulb, and chamfered forms. Using common names helps you and others stay on the same page when discussing joints. Use product data sheets or manufacturer instructions to verify which shapes are recommended for your joint width and movement range.

Each shape influences dirt shedding, water runoff, and cleaning ease in a different way. Geometry directs how particles move at the joint and how moisture dries or wicks away. Pros and cons for DIY installers vary by fabrication feasibility, potential snag points, and typical performance in indoor versus outdoor settings; choose based on traffic and exposure to dust or soil. Include simple visuals or references to show how each profile appears in a joint and how that appearance correlates with housekeeping outcomes. Tailor maintenance to the profile with the right tools, cleaners, and routine timing to minimize buildup without harming the sealant.

Low-trap profile families and when to use them

The best profiles for minimizing dirt buildup are those that don’t trap debris easily. Here’s a quick rundown:

Recessed/Concave: These profiles curve inward, allowing water and particles to flow through quickly.

Chamfered: Angled cuts at the joint edges help shed dirt and water efficiently.

Use these profiles where traffic is light to moderate, and sediment load is low. For heavy traffic or high dust areas, consider other options.

Designing profile depth, width, and slope for cleanability

The key to easy cleaning is a joint design that promotes water flow and prevents dirt accumulation.

Depth: Deeper joints can hold more water, but they also trap more dirt. Aim for a balance – typically 1/4 to 1/2 inch deep.

Width: Wider joints allow better water flow but may be harder to seal. Narrower joints (1/8 to 3/16 inch) are usually sufficient and easier to maintain.

Slope: A slight slope towards the center of the joint helps water runoff, preventing dirt buildup at the edges. Aim for a 1:4 or steeper slope.

Sealant Materials and Surface Properties That Resist Dirt Adhesion

Dirt adhesion is driven by surface energy, micro-roughness, and chemical compatibility. These factors explain why silicones, polyurethanes, polysulfides, acrylics, and elastomeric hybrids differ in how much dirt sticks. For each chemistry, verify the label or manufacturer guidance on surface preparation and compatibility with concrete and profile shapes.

Think of it as a quick comparison matrix: surface energy, abrasion resistance, and long-term fouling tendency guide maintenance needs. In-situ checks like contact-angle cues or visible fouling, plus observations after exposure to dirt, help you gauge performance. Consider how prep, porosity, and joint edge sharpness interact with dirt retention and cleaning; include notes on any profile compatibility with the chosen sealant. When cleaning, stick to recommended cleaners and intervals and watch for signs of fouling or loss of dirt resistance as a trigger to re-evaluate materials or profiles.

Surface texture, color, and finish choices

The way you finish your concrete joint sealant can help keep dirt at bay. A smooth finish reduces micro-roughness where dirt can stick.

Glazed or coated surfaces create a barrier that stops particles from adhering. Choose a coating with low surface energy to repel dirt.

Darker colors tend to show less dirt than lighter ones. But remember, they might make the area feel hotter under direct sunlight.

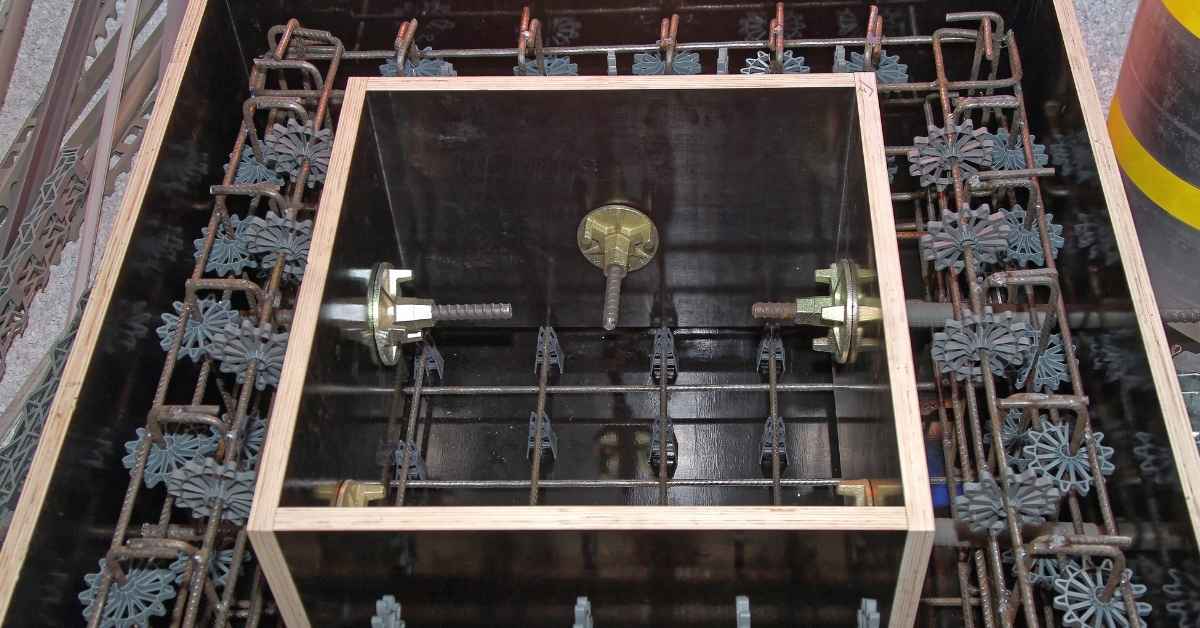

Backer materials and bond-breaker details

The right backer material and bond-breaker ensure your sealant stays in shape, preventing dirt traps. Here’s what to look for:

- Polyethylene backer rods: They’re flexible, durable, and won’t absorb moisture. Look for ones with a high compression resistance rating.

- Bond-breakers: These prevent the sealant from sticking to formwork. Use a compatible one with your chosen sealant type.

- Fiberglass or foam backer rods: They’re cheaper but less durable. Avoid them in high-traffic areas where they might compress and create dirt traps.

- Corrugated backer materials: These can help control sealant shape, but their grooves can trap dirt if not cleaned properly.

- Bond-breaker tapes: They’re easy to apply but may not be as effective in preventing bond as liquid bond-breakers. Use them where quick application is crucial.

Installation Best Practices to Minimize Future Dirt Tracking

Start with a dry, dust-free substrate and perform moisture testing so the sealant can adhere properly without chasing dirt. Remove cure debris and any oil or grease from joints before you apply backing and sealant. Follow local or manufacturer guidance on surface prep for the specific product you choose.

Backing rod size and material matter to control depth and keep the joint width within expectations for expansion and contraction. Avoid gaps that trap debris and misaligns the profile. Tooling should shape a smooth, continuous anti-dirt profile, with the preferred finish and cross-sectional shape to minimize dirt capture and maximize cleanability. Consider environmental factors like temperature and humidity during cure and protect joints from rapid shifts that can create micro-cracking and dirt adhesion.

Surface preparation and contamination control

The first step to a successful sealant application is a clean, dry substrate. Here’s how:

Scarify the surface: Remove any loose concrete or laitance using a scarifier or chipping hammer.

Moisture test and control: Test for moisture using a calcium chloride test kit. If present, address it before sealing. Keep the substrate dry until application.

Clean joints: Remove cure debris and any oil/grease from joints using a wire brush or compressed air. Wipe with a clean cloth dampened in solvent to remove dust and contaminants.

Tooling, cure conditions, and profile verification

Proper tooling and curing ensure a non-trapping sealant profile. Here’s how:

- Tool selection: Use finish tools like squeegees or trowels to achieve a smooth, continuous profile. Bevels help create the desired cross-sectional shape.

- Cure conditions: Maintain substrate and sealant temperatures between 50°F – 90°F (10°C – 32°C) during application and cure. Protect joints from rapid temperature shifts to prevent micro-cracking.

- Humidity control: Keep humidity below 85% for optimal curing. Use temporary barriers or mats to protect joints from dirt deposition.

- Profile verification: Inspect the sealant profile visually and with a straightedge to ensure it’s smooth, continuous, and free of voids or gaps that could trap dirt.

- Optional tools: Rentable tools like concrete profiling machines can help achieve consistent profiles. Expect to pay around $50 – $100 per day.

Cleaning and Maintenance Methods for Sealed Joints

First confirm the sealant type in use and review any manufacturer cleaning recommendations or restrictions. This helps you choose safe cleaners and methods that won’t degrade the joint over time. Gather a simple plan so maintenance is consistent across seasons and projects.

Adopt a tiered cleaning plan from routine dry methods to deeper cleaning while matching actions to the sealant chemistry. Link the cleaning approach to the joint profile shape since recessed or protruding profiles change how dirt accumulates. Develop practical rules of thumb, test methods on a small area, avoid high-pressure washing or aggressive solvents unless approved, and set a maintenance cadence that fits your conditions and traffic. Keep notes and look for signs that resealing or repair is needed to maintain cleanliness.

Routine cleaning and preventive maintenance

Regular inspections are key to keeping your sealed concrete joints clean. Here’s a simple routine:

Dry debris removal: Use a soft broom or vacuum to remove dust, dirt, and loose particles. This prevents buildup that can trap moisture and cause damage.

Low-impact washes: Occasionally use a mild soap solution with a soft sponge or cloth for a quick wash. Avoid high-pressure washers as they can damage the sealant.

Deep cleaning and stain removal without damaging sealant

For tougher stains, follow these guidelines:

Safe detergents: Use mild soaps or cleaners specifically designed for your sealant type. Always check the manufacturer’s recommendations.

Pressure-washing: If using a pressure washer, keep the pressure low (under 1200 PSI) and hold the wand at an angle to avoid damaging the sealant. Never use a zero-degree tip.

Test cleaners first: Always test any cleaner on a small, inconspicuous area before applying it to the entire joint. This ensures it won’t damage your specific sealant type. Avoid acetone and petroleum solvents as they can dissolve some sealants.

Compatibility with Reinforced Concrete Pipe (RCP) and Other Structures

Reinforced Concrete Pipe (RCP) is a ductile concrete system used in drainage and utilities, and understanding its context helps you pick the right sealant and profile. Check how joints are formed in RCP to choose compatible materials and shapes. Review the intended service environment and guidance on joint treatment for RCP applications.

Common RCP joint configurations include end-to-end, rubber-gasket, and crimped joints, each influencing sealant choice and profile shape. Environment plays a big role: soil contact, groundwater, de-icing chemicals, sulfates or chlorides, freeze–thaw cycles, and nearby traffic loads all affect dirt-tracking risk. Use field checks for moisture, substrate prep, cure compatibility with bedding materials, and follow-up maintenance plans to keep joints clean and functional over time.

RCP-specific considerations (movement, abrasion, sediment)

Reinforced Concrete Pipe (RCP) sees heavy-duty action. It’s buried in soil or water, carries waste, and handles traffic loads near roads. Here’s what you need to know:

Movement: RCP joints move due to soil settlement, temperature changes, and traffic. Sealants must accommodate this movement without failing.

Abrasion: Sediment in groundwater or soil can abrade joint surfaces. Choose a sealant with good abrasion resistance and consider profiles that minimize sediment buildup, like flush profiles.

Sediment also causes tracking. Profiles with sharp angles or deep recesses can trap dirt. Opt for low-trap profiles to reduce this risk.

Sidewalks, pavements, and wall joints—cross-application notes

Different concrete structures need different sealant profiles and maintenance:

Sidewalks & Pavements: These see foot and vehicle traffic. Choose a profile that’s easy to clean, like a flush or slightly rounded profile. Use a durable, abrasion-resistant sealant.

Wall Joints: These are exposed to UV and weathering. Opt for a UV-stable sealant with good adhesion. A trapezoidal or d-shaped profile can help water drainage.

Maintenance varies too. Sidewalks and pavements need regular cleaning, while wall joints may only require periodic inspection and re-sealing.

Costs, Longevity, Safety, and Environmental Factors

Costs come from materials, labor for prep and application, equipment, and ongoing maintenance. The profile shape and maintenance plan influence how much material you need and how long the job takes. Review safety considerations from sealant handling and curing fumes to required PPE and worksite ventilation; these affect both cost and safety planning.

Environmental factors like VOC content and disposal of sealant waste affect long-term viability and cleanup. Consider a simple cost model that tracks capex, opex, and maintenance; relate that to expected field performance for different profiles. Use quick decision criteria based on climate, traffic, and dirt exposure to pick profiles and schedules that minimize dirt tracking while staying within budget and safety guidelines.

Safety, VOCs, and environmental best practices

When applying concrete joint sealant, safety is paramount. You’ll need personal protective equipment (PPE), including gloves, goggles, and a respirator for dust protection.

Ventilation is crucial during application to keep fumes at bay. Opt for low-VOC or locally compliant materials to minimize health risks and environmental impact.

When removing old sealant or cleaning, use safe disposal methods. Follow manufacturer guidelines for waste management. Always wear PPE when handling chemicals.

When to reseal or replace: indicators and lifecycle planning

Regular inspection is key to maintaining your concrete joint sealant. Look for these signs of failure:

– Cracking: Small cracks can lead to bigger problems if left untreated.

– Peeling: If the sealant starts peeling, it’s time for a replacement.

– Dirt buildup: Excessive dirt tracking may indicate a worn-out sealant.

Inspect joints every 6-12 months, depending on traffic and exposure. In high-traffic or harsh environments, consider annual inspections. Reseal or replace as needed to maintain the joint’s integrity and prevent dirt tracking.

Common Mistakes, Troubleshooting, and Visual Checkpoints

The most common mistakes involve choosing the wrong profile for the joint, using incompatible sealant with concrete, or ignoring joint timing and movement. These issues often show up as faster dirt accumulation or early edge wear. Validate your choices against the joint’s movement and surface requirements using product data sheets or instructions.

Installation errors such as inadequate prep, insufficient cleaning, backing missteps, incorrect sealant depth, or tool marks increase tracking risk. A troubleshooting flow helps you diagnose by starting with a visual check, then performing simple tests, and finally deciding whether to re-clean, reprofile, reseal, or replace the profile. Use before/after photos and measurements to document conditions and guide future work. Establish quick-maintenance routines and compatible cleaners to simplify inspections and keep dirt under control.

Typical errors and how to avoid them

Before you start, review this checklist to prevent common mistakes that lead to dirt tracking.

- Profile shape: Ensure it matches joint width. Too narrow or wide increases dirt buildup.

- Sealant chemistry: Check compatibility with concrete. Incompatibility causes sealant failure and dirt penetration.

- Joint timing: Seal after initial cure but before final set to prevent premature failures due to movement.

- Joint prep: Clean, prime, and tool joints properly for a solid bond and even profile.

- Cleaning: Remove all dust, debris, and contaminants. Insufficient cleaning reduces sealant adhesion.

- Backing: Use proper backing rod size and placement to control sealant depth and prevent over- or under-filling.

- Sealant depth: Apply the right amount. Too little leaves gaps; too much causes bulging and dirt trapping.

- Tool marks: Avoid leaving visible marks on the sealant surface, as they collect dirt.

- Cleaners: Use compatible cleaners to prevent chemical reactions that damage sealant or concrete.

Quick rule: Regularly review this checklist before and during installation to minimize errors.

Visual checkpoints and decision guide for repairs

Regular inspections help maintain joint integrity. Use this checklist to assess sealant condition and decide on necessary actions.

- Sealant surface: Check for cracks, gaps, or discoloration indicating damage or failure.

- Joint edges: Ensure they’re well-defined and not crumbling. Crumbling indicates concrete deterioration.

- Dirt buildup: Inspect for excessive dirt, which may indicate sealant creep or improper profile shape.

- Water test: Apply water to the joint. If it beads up and doesn’t absorb, the seal is good. If it absorbs quickly, resealing is needed.

- Dye test: Use a dye solution to highlight cracks or gaps in the sealant.

- Joint movement: Gently push and pull on the joint to check for excessive movement, which may require reinforcement or replacement of the profile.

- Adjacent concrete: Inspect for signs of spalling, cracking, or other damage that could affect the sealant’s performance.

Quick rule: If you find issues during inspection, follow this decision tree: clean (if minor), spot repair (if localized), or full reseal/replace profile (if extensive).

Conclusion

Getting the joint sealant right protects durability, keeps dirt out, and makes the surface look clean and finished. Do it safely and you’ll avoid costly fixes later.

Check in this order: verify the substrate and joint shape, confirm the sealant is compatible with the concrete and any pipes or structures, prep and clean the joint area, apply and smooth the sealant, allow proper curing, and then inspect for finish and dirt resistance. Afterward, schedule periodic cleaning and visual checks so you catch issues before they grow.

Common mistakes sneak in: over or under filling the joint, skipping a proper cleaning before sealing, picking a sealant or surface treatment that isn’t compatible with the concrete or surroundings, and rushing curing or weather-proofing. Safety rules to follow include working in a well-ventilated area, using gloves and eye protection, testing any new product in a small area first, and never forcing a joint or using aggressive cleaners that could damage the sealant or concrete.

If you’re dealing with large joints, complex shapes, reinforced concrete pipe connections, or high-traffic or underground settings, consider a professional assessment before proceeding. With careful steps and steady work, you’ll end with a clean, durable joint that resists dirt and stays easy to maintain. Stay practical, stay safe, and keep moving forward.

FAQ

What is reinforced concrete pipe (RCP) and where is it typically used?

RCP is a concrete pipe with steel reinforcement inside to give it strength. It’s commonly used for culverts, storm sewers, and drainage lines under roads, yards, and landscaping projects. Look up the specific job site plans to confirm where it’s required for your project and what size or class is specified.

What should I know about the durability and lifespan of RCP materials?

RCP durability depends on the mix, reinforcement, and exposure environment. Check the manufacturer’s datasheet or project specs for guidance on expected service life and maintenance needs. Local conditions can change wear and joint behavior, so verify what applies to your site.

How does joint sealant choice affect RCP and nearby structures?

Choose a sealant compatible with concrete and the pipe joint design. Always confirm with the pipe manufacturer or project specs to ensure the sealant won’t degrade the joint or trap dirt near RCP connections. If in doubt, test a small area or ask for a manufacturer-approved option.

What practical checks should I perform before sealing joints around RCP installations?

Ensure surfaces are clean, dry, and free of loose material. Verify joint geometry matches the sealant’s required profile and that curing times won’t clash with your workflow. Refer to product labels and instructions for any restricted conditions or temp requirements.