Introduction

Stucco over ICF walls means applying a cement-based veneer to insulated concrete forms using a proper weather-resistive layer, reinforcement mesh, and secure fasteners so the finish sticks and moves with the wall. This job needs the right mesh type, fastener method, and detailing at windows and doors to control cracking; check the stucco manufacturer’s installation instructions and any local building requirements before you start. Keep it practical: plan for access, curing, and the extra weight a scratch-coat adds when choosing anchors and support.

For DIY work, think in terms of three tasks—attach a WRB or bond coat, embed reinforcing mesh, and apply scratch/finish coats—while keeping openings detailed with backer rod, sealant, and movement joints to prevent stress cracks. If you’re unsure about a product or a required spacing/fastener length, consult product labels or a local inspector and err on the side of heavier reinforcement and controlled joints rather than skimping. Focus on firm, level surfaces, neat mesh overlaps, and good edge treatment at openings to get a durable result.

Key takeaways

- Verify that stucco over ICF uses approved mesh, coatings, and expansion joints.

- Choose mesh types compatible with ICF from manufacturer guidance and local codes.

- Install fasteners and anchors using ICF methods; avoid foam damage; follow instructions.

- Control cracks at openings with movement joints, proper sealants, and reinforced lintels where needed.

- Perform sealing, base coats, and finish coats with consistent workmanship and visual checks.

- Plan for codes, inspections, and Georgia requirements; document readiness and safety protocols.

Table of Contents

- Introduction

- Key takeaways

- Why Choose Stucco over ICF Walls — Benefits and Trade-Offs

- Preparing ICF Walls for a Successful Stucco Application

- Step-by-Step Mesh Installation Techniques for ICF Walls

- Choosing Fasteners and Anchors for Stucco over ICF

- Crack Control and Movement Treatment at Door and Window Openings

- Sealing, Base Coats, Finishing, and Visual Quality Checkpoints

- Codes, Inspections, and Georgia-Specific Requirements for Stucco on ICF

- Cost Planning, Tools Checklist, Safety, and Common Mistakes to Avoid

- Conclusion

- FAQ

Why Choose Stucco over ICF Walls — Benefits and Trade-Offs

Stucco over insulated concrete form (ICF) walls brings real-world benefits: added exterior thermal mass, a durable wearing surface, and an opportunity to tailor the exterior assembly’s vapor and drainage strategy. Check product data sheets and local rules to confirm how a chosen stucco system interacts with the ICF’s foam insulation and what that means for overall thermal performance.

Expect trade-offs installers deal with on site: moisture-management details, potential need for drainage planes or EIFS-style layers, and extra detailing at openings to prevent water intrusion. Verify flashing and sealant instructions and plan for labor that may be more specialized than traditional stucco on masonry, since perimeter detailing, mesh selection, and crack-control strategies all affect long-term durability and maintenance.

Thermal performance and insulation effectiveness

Stucco over ICF walls boosts thermal efficiency. Here’s how:

R-value boost: Stucco adds R-0.1 to R-0.2, enhancing the ICF’s base R-value of 23 or more.

Thermal mass: Stucco absorbs and releases heat slowly, stabilizing indoor temps. This complements ICFs’ insulation.

Thermal bridging: Proper detailing at openings minimizes thermal bridging, ensuring continuous-insulation performance.

Durability, weather resistance, and aesthetic benefits

Stucco enhances ICF walls’ durability and appearance:

Weather resistance: Stucco’s thick, durable layer protects against wind, rain, and UV. It complements ICFs’ inherent strength.

Finish options: Stucco offers various textures and colors, letting you customize your home’s look while maintaining a consistent finish with ICF construction.

Maintenance needs: While durable, stucco may require periodic touch-ups or cleaning to maintain its appearance. Regular inspections help spot any issues early.

When to use cement stucco vs. synthetic finishes on ICF

Choose the right stucco system for your ICF walls:

Cement-based (Portland): Ideal for traditional, long-lasting finish. It’s breathable, compatible with ICFs’ moisture management, and suitable for most climates.

Synthetic/acrylic: Great for areas with high humidity or frequent freeze-thaw cycles. They offer better flexibility, color retention, and easier application but may not breathe as well as cement-based systems.

Choose based on: Climate, desired finish, budget, and local codes. Consult with a pro if unsure.

Preparing ICF Walls for a Successful Stucco Application

Preparation starts with assessing the wall’s moisture condition and substrate soundness; confirm dryness indicators and any manufacturer guidance on acceptable moisture levels before priming or attaching mesh. Inspect for delamination, uneven foam or concrete, and damage around openings, and plan repairs so the surface is flat enough for lath and base coats.

Clean the surface of dust, oil, form-release agents, and loose particles and choose a bonding agent or primer compatible with both the ICF material and the stucco system being used. Lay out flashing, sealant products, control-joint locations, mesh type, and fastener pattern ahead of work and follow product labels or manufacturer instructions where they dictate attachment sequence and environmental limits.

Cleaning, drainage plane, and weather-resistive barrier (WRB)

Start by removing any form ties or residue from the ICF surface. This ensures a clean base for your stucco application.

Verify that a weather-resistive barrier (WRB) is in place behind the ICF walls. If not, install one to prevent moisture buildup and potential mold growth.

Check drainage and ventilation behind the ICF walls. Ensure there’s no trapped water or lack of airflow, which could lead to moisture issues later on.

Starter strips, weep screeds, and termination details

Install starter strips at the foundation level. These help direct water away from the walls and prevent moisture buildup.

Add weep screeds at the top of your foundation. They allow any trapped water to escape, preventing pressure buildup behind the stucco.

Plan termination details at grade level. This includes proper flashing and sealant application where the stucco meets other materials like brick or siding.

Inspecting and repairing ICF surfaces and penetrations

Thoroughly inspect your ICF walls for any voids, tie defects, or other surface imperfections. Address these issues with appropriate patching materials.

Check for utility penetrations like pipes or wires. Ensure they’re properly sealed to prevent moisture intrusion.

Repair any damaged areas around openings, corners, and transitions before applying mesh and stucco. This helps ensure a smooth, even finish.

Step-by-Step Mesh Installation Techniques for ICF Walls

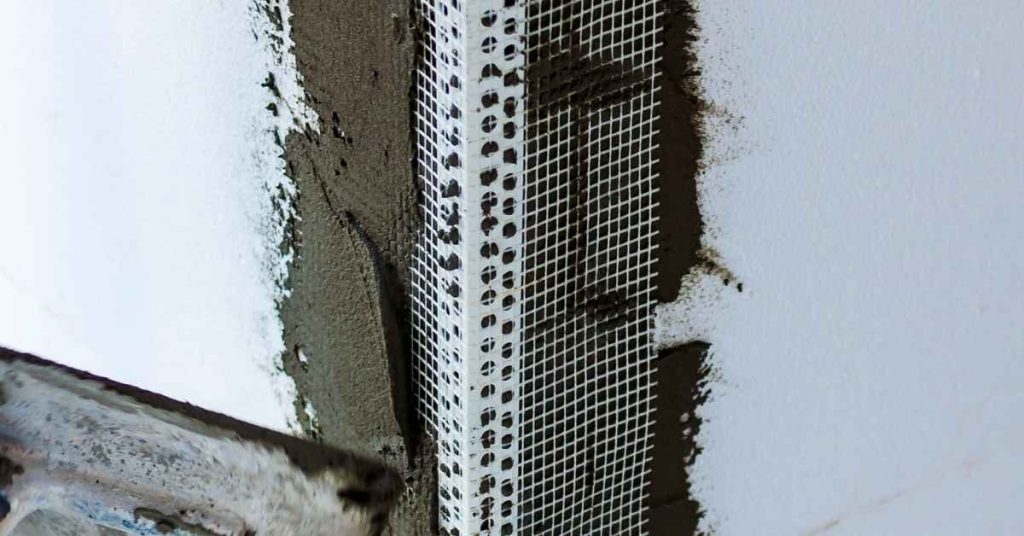

The mesh’s job is to create a smooth, continuous plane that controls cracks and accepts the base coat; select the AR mesh and plan laps so seams fall in low-stress areas. Prepare the ICF surface—clean, prime if required, and mark fastener lines and opening transitions so the mesh lays flat and uninterrupted across window and door perimeters.

Start at a corner or edge and secure mesh with the chosen fasteners in a consistent pattern, shingling laps in the working direction and keeping the mesh taut to avoid fish-mouths; tuck and trim mesh neatly around openings, using corner reinforcement where needed. Confirm embedment with the first base coat, inspect laps and fastener zones for voids, and correct wrinkles or misaligned seams before proceeding with further coats.

Step-by-Step Installation Process

This step-by-step guide walks you through the practical process of installing mesh over ICF walls, ensuring a flat plane and proper lap joints for your stucco or EIFS application.

- Preparation: Inspect ICF surfaces, gather materials (mesh, fasteners, primer), and ensure safety measures are in place. Why: A clean, safe workspace ensures quality results.

- Priming: Apply a thin, even coat of primer to the ICF surface. Why: Primer improves mesh adhesion and seals the surface.

- Main Mesh Installation: Starting from the bottom, unroll and secure mesh using recommended patterns and spacing. Ensure continuous lapping at seams. Why: Proper securing prevents wrinkles and ensures lap integrity.

- Check for Flatness: Inspect mesh for any wrinkles or fish-mouths around openings. Use a straight edge to ensure flatness. Why: A flat surface promotes even stucco application.

- Final Checks: Verify all mesh is taut, laps are aligned, and fasteners are secure before applying the base coat. Why: Thorough checks prevent costly rework.

Cutting, positioning, and overlapping mesh

Properly cutting, positioning, and overlapping your mesh ensures a flat plane and maintains lap integrity over ICF walls.

Use alkali-resistant (AR) metal or fiberglass mesh, cut to size with tin snips or a utility knife. Allow for 1-2 inches of overlap at seams.

Position mesh so laps are staggered, not aligned vertically. This distributes stress evenly and prevents cracks from propagating through multiple layers.

Keep mesh flat over corners and curves by using a straight edge to guide positioning and gently pulling the mesh taut as you secure it.

Securing mesh before base coat — patterns and spacing

Secure your mesh tightly with fasteners to prevent movement and maintain lap integrity. Use a recommended pattern, such as staggered or diamond, for even stress distribution.

Space fasteners according to manufacturer’s guidelines, typically every 4-6 inches along the edges and 6-8 inches in the field. Why: Proper spacing ensures mesh is held tight without creating stress points.

Use appropriate fasteners for your mesh type (nails, staples, or screws) to ensure proper embedment into the base coat.

Inspect fasteners after installation to ensure they are secure and flush with the mesh surface. Why: Properly seated fasteners prevent voids in the stucco.

Special details at corners, reveals, and parapets

Corners, reveals, and parapet caps are high-stress areas that require extra reinforcement. Use corner beads or tape to bridge the gap between walls and maintain lap integrity.

At corners, apply corner bead or tape before installing mesh. Secure mesh over the bead, ensuring it is fully embedded in the base coat. Why: Corner reinforcement prevents cracking at high-stress points.

For reveals and parapet caps, use a wider mesh (e.g., 36-inch) to provide extra coverage. Install mesh with additional fasteners along edges and curves. Why: Extra reinforcement prevents cracking due to increased stress.

Inspect these areas closely after installing the base coat to ensure proper embedment of mesh and corner reinforcements.

Choosing Fasteners and Anchors for Stucco over ICF

Select corrosion-resistant fasteners compatible with the mesh and stucco environment, and confirm allowable penetration and embedment depth from the fastener and ICF manufacturers. Verify required lengths and pull-out guidance on product literature so fasteners pass through the lath and engage the ICF shell or backing without contacting internal components or leaving excessive protrusion.

Lay out spacing, staggered rows, and edge reinforcement based on manufacturer recommendations or testing, and use washers or backing plates where necessary to spread load at seams and openings. Follow best-practice installation steps—predrill where recommended, avoid overtightening, and check compatibility of fastener coatings with sealants and stucco chemistry per the product technical data.

Fastener types, lengths, and embedment guidelines

When it comes to securing stucco to ICF (Insulated Concrete Forms), you’ve got options. But remember, the wrong fasteners can cause big issues down the line.

Concrete Screws are your best bet for most jobs. They’re designed to grip concrete and won’t rust like nails. Go for ones with a coarse thread and a flat head. Check the label, but generally, you’ll want them to be at least 2″ longer than the thickness of your ICF wall.

As for embedment, drive those screws in deep. Aim for about 1.5 times the screw’s diameter into each wythe (layer) of concrete. So if you’re using a 1/4″ screw, that’s 3/8″ deep per wythe. But check your specific ICF system’s recommendations, as some might have different guidelines.

If you’re using Anchors, make sure they’re designed for concrete and can handle the load you’re putting on ’em. Follow the manufacturer’s instructions for embedment depth, but it’s usually around 1″ to 1.5″. And don’t forget to use a washer to spread out the pressure.

Fastener spacing, patterns, and pull-out considerations

Alright, listen up. You’ve picked your fasteners, now let’s talk about how to use ’em right.

First off, spacing. Don’t go crazy with those screws. For ICF forms, stick to a max of 6″ on center for both vertical and horizontal spacing. Any closer and you’re just wasting money. Check your manufacturer’s instructions if you’re unsure.

Now, patterns. You want a nice, even stagger. Think bricklaying – offset each row by half the width of your ICF block. This spreads the load and keeps your stucco looking sharp. Don’t be lazy and go all straight lines, it’ll weaken your wall.

Lastly, pull-out strength. You don’t want your screws popping out like popcorn. Before you start screwing away, check base compaction. It needs to be solid as a rock. Then, embed those fasteners at least 1″ into the ICF foam. If it’s not holding, try longer screws or switch to a different type.

Corrosion resistance and material compatibility

The fasteners and anchors you choose for your stucco over ICF project need to stand up to moisture, salt, and time. Here’s what you should look for:

- Stainless Steel (SS): Ideal for coastal or high-humidity climates. Look for SS304 or SS316 with a minimum corrosion resistance rating of C5-M/C6. They’re pricier but worth it to avoid rust.

- Hot-Dipped Galvanized (HDG): Cheaper than stainless, HDG provides good protection in most climates. Ensure they have a zinc coating thickness of at least 1.2 mils for adequate corrosion resistance. Avoid in coastal areas without additional protection.

- Coated Fasteners: These are cheaper still but offer less long-term protection. Look for fasteners with a heavy-duty, multi-layered coating. Check the label for expected lifespan and re-coat intervals.

- Plastic Anchors: Suitable for light-duty applications where corrosion isn’t a concern. They’re cheap but won’t last as long as metal anchors. Use only in dry, interior areas or where loads are minimal.

- Expansion Anchors: For concrete, use expansion anchors with a minimum pull-out strength of 500 lbs. Check local codes for specific requirements. Avoid using them in ICF unless specifically designed for it.

Using the wrong fasteners can lead to rust stains on your stucco, weakened bond, and even structural issues over time. Always check product labels and manufacturer instructions. For coastal areas or high-humidity climates, consider hiring a professional if you’re unsure.

Pro tip: Buy fasteners in small quantities first to ensure they work with your ICF and stucco mix. Store them in a dry place until use to prevent corrosion. Always wear gloves when handling galvanized or stainless steel to avoid fingerprints on the metal.

Crack Control and Movement Treatment at Door and Window Openings

Cracking around openings most often comes from differential movement, thermal cycling, and improper joint detailing; identify whether cracks are surface shrinkage or a sign of larger movement before repairing. Plan control joints and movement joints aligned with building breaks and opening edges, and consult product guidance for recommended joint placement relative to the ICF geometry.

Reinforce openings with wrap-around mesh, corner reinforcement, and continuous crack-control fabric that ties into flashing and sealants to keep water out while allowing movement. Use the fasteners and backer details specified by the system manufacturer at jambs, sills, and heads, and document ongoing inspections to detect movement early and make timely repairs per the manufacturer’s repair guidance.

Placement of control joints and movement joints near openings

When it comes to door and window openings, you gotta play by different rules. These spots are where your concrete wants to crack most.

Control Joints: You should place these about 24″ to 36″ apart around windows and doors. Start from the outer edge of the opening and go inwards. That way, you’re guiding the concrete where it can safely crack instead of letting it happen randomly.

Movement Joints: These are wider than control joints and let your concrete move without cracking. Place them about 12″ to 18″ from the edge of openings. Remember, these aren’t just for expansion; they also allow for contraction during cold weather.

Reinforcing jambs, sills, and heads with mesh and back-blocking

Alright, listen up. You’ve done your control joints right? Good. Now let’s beef up those door and window openings.

First off, check your mesh size. It should match what you’re using on the walls. Most jobs call for 1/2″ or 3/4″. Don’t go too small, won’t hold up. Too big? Waste of money.

Now, back-blocking. This ain’t no optional extra. It’s a must. You want to prevent those cracks from running right through your opening. Here’s how:

Start at the bottom, sill. Lay a strip of mesh across, tuck it into the formwork. Then, pour your concrete and let it set up a bit. Once it’s starting to hold its shape, you can back-block. Use a trowel or a small shovel, pack that concrete right up against the mesh. Do this for both sides of the opening.

Next, jambs. Same deal. Lay your mesh, let it set, then back-block. Top and bottom. Don’t be lazy, get in there and make sure it’s packed tight.

Finally, head. You’re almost done. Lay your mesh, let it set, then back-block. Easy peasy.

Now, some folks like to wrap the whole opening in a full layer of mesh before they pour. That’s fine too. Just make sure you’ve got good contact with the wall mesh and you’re not just floating it out there.

Flashing integration, backer rods, and sealant choices

When it comes to door and window openings, integrating flashing with mesh is crucial. Flashing should be installed before you apply the mesh. It helps direct water away from your openings.

Check your local building codes for specific requirements on flashing. Typically, you’ll use a minimum of 12″ wide flashing at the head and sides, and 8″ at the sill. Overlap the flashing properly to ensure water doesn’t seep in.

For gaps between the mesh and framing, or around pipes and wires, use compressible backer rods. These prevent sealants from breaking due to movement. They come in various sizes, so choose one that fits your gap snugly but allows for some compression.

For exterior sealants, go with a high-quality, paintable, and flexible option. Silicone-based or polyurethane sealants work well. They should be compatible with your mesh and flashing materials. Always check the product label before purchasing.

Sealing, Base Coats, Finishing, and Visual Quality Checkpoints

Before base coats, confirm moisture levels and flashing at openings are complete, and choose a sealing strategy that matches the stucco system and local requirements; consult product labels for compatibility with ICF substrates. Mix and apply the base coat to fully embed mesh with consistent thickness, following manufacturer instructions for mixing and application techniques.

Select a finish coat compatible with the base (polymer-modified, acrylic, or cementitious per the system) and detail terminations around openings to maintain water shedding and crack control. Perform visual checkpoints for uniform thickness, feathered transitions, and sealant/flashings integrity, and run a water or visual test on critical details before final acceptance.

Base coat thickness, curing, and multi-coat sequencing

Use this checklist after applying each base coat to ensure proper curing and thickness for a strong, crack-resistant finish.

- Check base coat thickness: Use a straight edge and level to measure. Aim for 1/4″ – 3/8″ (6mm – 9mm) per coat.

- Verify trowel notations: Check trowel notations on the mix design or product label to ensure you’re using the right one for your base coat.

- Inspect surface before next coat: Look for any imperfections, cracks, or contaminants. Clean and repair as needed.

- Check humidity and temperature: For proper curing, humidity should be above 40% and temp between 50°F – 90°F (10°C – 32°C). Check local rules if unsure.

- Cure for recommended time: Follow manufacturer’s instructions. Typically, cure for 24-72 hours before applying the next coat.

- Avoid overworking surface: Too much troweling can lead to excessive water loss and weak spots. Keep passes even and consistent.

- Check for proper bonding: Before applying the next coat, perform a simple pull test with duct tape. If it pulls off easily, recheck your surface prep and curing.

- Inspect edges and corners: These areas are prone to cracking. Ensure they’re well-saturated and reinforced if needed.

Quick rule: Always cure properly between coats. Skipping this can lead to weak bonds, excessive shrinkage, and costly rework.

Finish coat options, application tips, and texture control

Use this checklist when applying the final layer of concrete finish to ensure a uniform texture and strong adhesion over Insulated Concrete Forms (ICF).

- Check finish type: Confirm if you’re using smooth, exposed aggregate, or stamped finishes.

- Inspect ICF surface: Ensure ICF is clean, dry, and free of debris. Any residue may affect adhesion.

- Apply base coat: Verify base coat (usually 3/8″ to 1/2″) is cured and ready for finish coat. Check manufacturer’s instructions for cure time.

- Check finish mix design: Ensure your final concrete mix matches the required slump, air content, and strength for your chosen finish.

- Control water-cement ratio: Maintain a consistent water-cement ratio (0.45 to 0.60) for proper hydration and finishability.

- Monitor temperature: Keep concrete temperature between 50°F to 70°F (10°C to 21°C) for optimal setting and finishing.

- Check humidity: Maintain relative humidity above 40% to prevent rapid water loss and surface cracking.

- Control application rate: Apply finish coat evenly, avoiding over-application or under-application that can lead to inconsistent texture.

- Use proper tools: Use appropriate floats, trowels, and brushes for your chosen finish. Check tool condition; dull tools can cause surface defects.

Quick rule: Always follow the manufacturer’s guidelines for your specific concrete mix and finish type to avoid costly rework or poor results.

Visual checkpoints and water-testing before project closeout

Before signing off on your concrete project, use this checklist to ensure proper installation and protection against water intrusion. Perform these checks after the final finish coat has cured.

- Check Flashing: Inspect all joints, control, and expansion joints for proper flashing installation. Look for any gaps or missing pieces. What goes wrong if you skip this: Water can seep in, causing cracks and deterioration.

- Inspect Sealants: Ensure sealants at expansion and construction joints are intact and show no signs of cracking or peeling. Press gently to check for adhesion. What goes wrong if you skip this: Water and debris can enter, leading to joint failure.

- Check Curing: Verify that the concrete has been properly cured. It should have a consistent, uniform appearance with no signs of excessive drying or cracking. What goes wrong if you skip this: Inadequate curing can lead to weak, porous concrete.

- Inspect Control Joints: Ensure control joints are clean and free of debris. They should be well-defined and show no signs of premature cracking. What goes wrong if you skip this: Poorly maintained control joints can cause random cracks due to unmanaged shrinkage.

- Check Surface Texture: Confirm the finish coat has provided the desired texture and slip resistance. Use a penny test (place a penny on the surface; if it slides, the texture is too smooth).

- Water Test Joints: Apply water to joints using a spray bottle or garden hose. Watch for any signs of leakage. What goes wrong if you skip this: Undetected leaks can cause hidden damage over time.

- Check Slope: Verify that the concrete surface has proper slope (usually 1/4″ per foot) to facilitate water runoff. Use a level or string line for accuracy. What goes wrong if you skip this: Improper slope can lead to standing water, causing damage and creating slip hazards.

- Inspect Edges: Check all edges (curbs, walls) for proper sealing and adherence to the concrete surface. Look for any signs of delamination or cracking. What goes wrong if you skip this: Poorly sealed edges can allow water intrusion, leading to structural issues.

Quick rule: Always perform these checks after a rainstorm or during sprinkler operation for added assurance.

Codes, Inspections, and Georgia-Specific Requirements for Stucco on ICF

Check the currently adopted state and local codes and any Georgia amendments that affect exterior-wall assemblies, moisture management, and EIFS/stucco interfaces with ICF; use the code texts and local plan-review checklists when preparing submittals. Make sure construction documents show flashing, control joints, and material specs called out so reviewers can confirm compliance with Georgia-specific modifications.

Understand the likely inspection sequence—substrate and flashing checks before stucco, in-progress base-coat and mesh inspections, and final acceptance that confirms sealants and drainage features are installed per plan. Prepare a local checklist for plan reviewers and inspectors including approved materials, flashing details at openings, energy and fire-resistance items, and any documentation required by Georgia authorities or the local building department.

What to check in local codes and manufacturer approvals

Before you start, confirm your project aligns with local codes and manufacturer requirements.

- Local code sections: Check for specific rules on stucco over ICF in your jurisdiction’s building codes.

- Approved assemblies: Ensure the chosen system is approved by your local authority having jurisdiction (AHJ).

- Manufacturer-listed systems: Verify the manufacturer lists the specific ICF and stucco combination for warranty compliance.

- Moisture management: Check if your system meets local requirements for moisture barriers and drainage.

- Fire-resistance ratings: Ensure the assembly meets required fire-resistance ratings.

- Energy codes (IECC): Confirm the system complies with energy efficiency standards.

- Flashings and penetrations: Check if specific flashings or penetration details are required around openings.

- EIFS vs traditional stucco: If using EIFS, confirm it’s compatible with ICF and meets local requirements.

Quick rule: Always check the latest codes and manufacturer listings to avoid costly rework or rejection.

Inspection documentation and common approval pitfalls

Keep detailed records and anticipate potential issues during inspections.

- Footing inspection: Ensure the footing is properly formed, reinforced, and cured before proceeding with ICF installation.

- ICF wall conformance: Verify the ICF walls are plumb, level, and square before applying stucco.

- Moisture barrier inspection: Check that the moisture barrier is properly installed and continuous.

- Flashing at openings: Ensure flashings are correctly installed around windows, doors, and other penetrations.

- Crack control detailing: Verify control joints and movement joints near openings are properly placed and detailed.

- Thermal/moisture barrier inspection: Check that the thermal/moisture barriers are correctly installed and continuous.

- Final occupancy inspection: Prepare for a thorough final inspection to ensure all systems are functioning as designed.

- Georgia amendments acknowledgment: Ensure your plans acknowledge any Georgia-specific amendments or requirements.

Quick rule: Keep detailed records and anticipate potential issues to streamline the inspection process.

Referencing Georgia amendments and how to verify updates

Stay current with Georgia’s building codes and amendments to avoid compliance issues.

- 2024 IBC/IRC/IPC/IFGC/IECC editions: Familiarize yourself with the latest versions adopted by Georgia.

- Georgia amendments (2026): Check for any specific Georgia amendments impacting stucco on ICF, especially those affecting EIFS, moisture management, and exterior wall assemblies around openings.

- State Codes Advisory Committee (SCAC) review: Be aware of any SCAC review or affidavit requirements for your project.

- Local jurisdiction requirements: Contact your local building department to confirm any additional or unique requirements.

- Plan-review appeals documentation: Know the required documentation and process for plan-review appeals in case of disputes.

- Revisions after initial approvals: Understand how revisions are handled after initial approvals to avoid compliance issues later on.

Quick rule: Regularly check for updates and contact local building departments to ensure your project remains in compliance with the latest Georgia codes.

Cost Planning, Tools Checklist, Safety, and Common Mistakes to Avoid

Create a budget that separates materials, labor, rental equipment, disposal, and permit costs and include a small contingency for onsite discoveries; double-check quantities and waste assumptions against the wall area and number of openings. Assemble a tools-and-materials list—mixers, trowels, hawks, mesh, corrosion-resistant fasteners, bonding agents, sealants, scaffolding, PPE—and verify quantities against manufacturer coverage rates.

Prioritize safety: use fall protection on heights, manage dust and ventilation, and enforce proper ladder and scaffold practices. Avoid common errors such as skimping on substrate prep, using incorrect fastener lengths or spacing, neglecting flashing at openings, and ignoring product installation instructions or local code requirements; when in doubt, consult the product technical data sheet or local inspector before proceeding.

Budget line items and cost-saving considerations

Use this checklist before starting your concrete project to ensure you’ve covered all budget aspects. Review it with your supplier or contractor to avoid oversights.

- Reinforcement Mesh: Check dimensions (e.g., 6×6, 12×12) and spacing (e.g., 12″, 18″) match plans. Verify it’s galvanized or epoxy-coated for corrosion resistance.

- Fasteners (Ties/Welded Wire): Ensure they’re the correct size (e.g., #3, #4) and spacing (match mesh). Check if they’re included in your mesh purchase or need separate ordering.

- Concrete Mix Design: Confirm mix proportions (e.g., 3000 psi, 4000 psi) meet project requirements. Ask for a detailed mix design from the supplier.

- Cement and Aggregates: Verify they’re fresh and of consistent quality. Check for any signs of contamination or deterioration.

- Water: Ensure water is clean, free of contaminants, and within the safe pH range (6-8). Test if unsure.

- Admixtures: Confirm type (e.g., air-entraining, water-reducing) and dosage match project needs. Check they’re compatible with your cement type.

- Sealants and Curing Compounds: Verify they’re suitable for your climate and concrete type. Check if they’re included in your project cost or need separate purchase.

- Labor Costs: Get clear quotes including setup, pouring, finishing, and cleanup. Ask about overtime rates and any additional charges.

Quick rule: Always get at least three quotes from reputable suppliers or contractors to ensure you’re getting a fair price.

Tools and materials checklist for DIY and contractor teams

Use this checklist before starting your concrete project to ensure you have everything needed. It’s best to gather all tools and materials at once to avoid mid-project delays.

- Tape measure: Verify it’s in good working condition and calibrated correctly.

- Level: Check for bubbles to ensure accuracy. A 2′ or 4′ level is standard for most jobs.

- Shovel: Ensure it’s sturdy and the handle is secure. A square-nose shovel is versatile for concrete work.

- Wheelbarrow: Inspect wheels for proper inflation and ensure the wheelbarrow is stable.

- Concrete mix: Check the bag label for the correct mix type (e.g., fast-setting, high-strength) and that it’s within its expiration date.

- Water: Ensure a clean water source is available. Too much or too little water can ruin your concrete.

- Concrete mixer (optional): If using, check that it’s in good working order and has the right capacity for your project.

- Forms: Inspect for damage. Ensure they’re sturdy enough to hold the concrete’s weight.

- Reinforcement (rebar or wire mesh): Check dimensions match your plans. Verify it’s in good condition with no kinks or bends.

- Fasteners: Nails, screws, or bolts? Ensure you have the right type and size for securing forms.

- Personal Protective Equipment (PPE): Include safety glasses, gloves, steel-toed boots, hard hat, and ear protection if needed.

Quick rule: Always double-check your measurements before mixing concrete. Incorrect amounts can lead to weak or poorly finished slabs, causing expensive rework.

Safety precautions, common mistakes, and troubleshooting tips

Use this checklist before starting work to ensure safety and prevent costly errors.

- Wear appropriate PPE: Helmet, gloves, boots, and safety glasses. Check they’re in good condition and fit properly.

- Fall protection: If working at heights, secure fall arrest systems as per local regulations. Check anchors and harnesses before use.

- Mixing safety: Wear gloves when handling cement. Avoid contact with eyes and skin. Always follow manufacturer’s mixing instructions on the bag.

- Application safety: Keep concrete away from power lines, avoid electrical hazards. Ensure proper ventilation in enclosed spaces.

- Insufficient flashing: Check all windows and doors have proper flashing to prevent water intrusion. Missing or inadequate flashing can lead to leaks and structural damage.

- Wrong fasteners: Verify you’re using the correct fasteners (nails, screws) for your application. Using wrong ones can cause concrete to delaminate or crumble.

- Inadequate curing: Check that concrete is cured properly to prevent cracking and reduce strength loss. Keep it moist for at least 7 days, following manufacturer’s recommendations.

- Proper finishing: Ensure concrete is finished smoothly with no air pockets or voids. Improper finishing can lead to weak spots and an unsightly surface.

Quick rule: Always double-check your work as you go, and don’t hesitate to ask for advice if unsure. A little extra time spent now can save a lot of rework later.

Conclusion

With stucco over ICF walls, the key payoff is a durable, good‑looking finish that holds up to Georgia weather when you stay disciplined about prep, fasteners, and movement at openings. Prioritize solid crack control, proper mesh installation, and correct sealing and base coats to keep the finish from failing or needing costly repairs.

First, inspect and prepare the surface, then verify openings move correctly, and plan your base coats, sealant, and finish in the correct sequence. Next, check mesh installation and fasteners in the right pattern and spacing, test a small area, and confirm you have the recommended fasteners and anchors for your wall type. Finally, set a realistic curing window, perform a visual quality check, and complete any Georgia‑specific inspections or code steps before you call it done.

Common mistakes to avoid are skipping crack movement control at openings, over‑ or under‑driving fasteners, and skipping the test patch or small‑area trial before full application. Use a clean, dry surface, follow the exact base coat and sealant sequence, and keep safety gear on during every step. If you’re unsure about mesh coverage, crack control at a particular opening, or meeting local Georgia requirements, pause and verify with a pro or local inspector before proceeding.

When in doubt about complexity, or if you face unusual movement or window details, it makes sense to bring in a pro rather than push through and risk damage. Stay focused, work in stages, and you’ll finish with a solid, professional look you can be proud of.

FAQ

What are the general requirements for stucco over ICF walls?

Make sure the ICF surface is clean, dry, and free of defects. Use proper mesh, base coats, and crack-control provisions, and follow manufacturer instructions for the stucco system. Always check local rules and product labels for compatibility and installation steps.

What types of mesh are suitable for ICF applications?

Common options are metal lath or reinforced fiberglass mesh rated for stucco. The mesh should be corrosion resistant and compatible with the base coat. Check the product label and manufacturer guidance for mesh type, mesh size, and embedment requirements.

How should fasteners be installed on ICFs?

Use fasteners and anchors rated for foam block substrates and stucco systems. Install according to the anchor manufacturer’s instructions, and ensure they sit flush with the finish plane. Verify spacing, edge distances, and any through-wall fastening recommendations with product labels or local rules.

How can I prevent and repair cracks at openings?

Control joints and proper lath detailing help. Use crack-isolation or sealant products compatible with stucco at openings, and reinforce with backing beads if needed. If you see cracks, repair with the approved base coat and mesh, then recoat, following the manufacturer’s directions and local requirements.

What safety considerations should I keep in mind during stucco application over ICF?

Wear eye protection, gloves, and a dust mask. Scaffold or stairs must be stable and rated for the job, with fall protection where required. Follow safety guidelines on the product label and your local rules when working at openings or elevated surfaces.