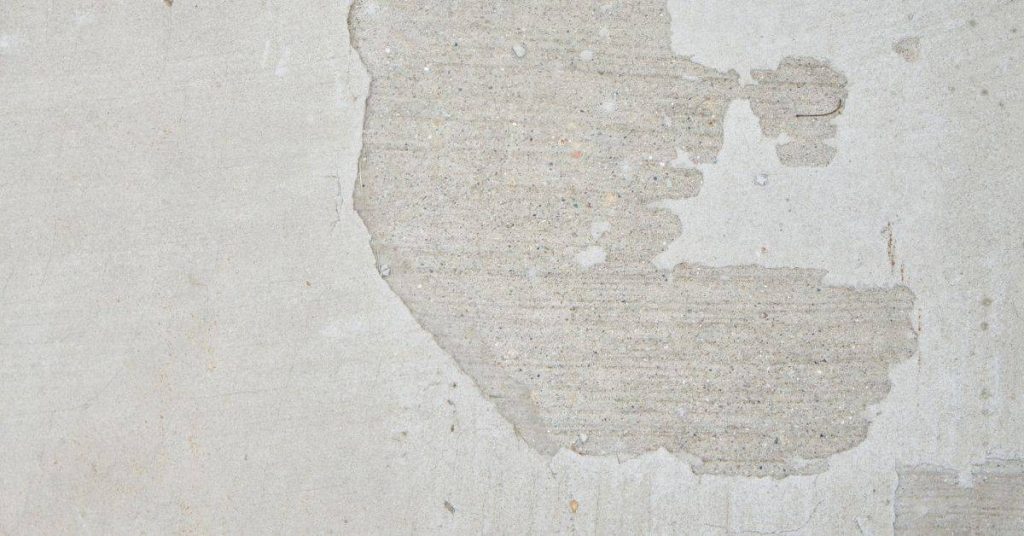

Reading water stains around concrete slabs: simple drainage diagnostics before you start digging

Introduction Water stains around a concrete slab signal drainage or seepage issues that should be diagnosed before you start digging. Observing the pattern, size, and timing of stains helps you understand where water is coming from. Use these clues to plan simple, noninvasive checks first. Look for common signs of leaks such as damp patches, […]