Introduction

Repairing stucco soffits means fixing the underside of eaves where stucco has cracked, sagged, or pulled away using proper support, fasteners, and mesh so the repair resists gravity and future movement. Start by assessing the damage and plan how gravity fasteners and mesh will transfer loads back to solid framing; check product labels and local rules for allowable fastener types and spacing. Keep the job practical: pick materials you can handle, get the right mesh and fasteners, and allow safe access to the work area.

This is a hands-on DIY task that mixes tear-out, substrate prep, and careful installation of crack-resistant mesh and gravity-rated fasteners to hold the stucco and lath in place. If you’re unsure about fastener pullout, stucco mix proportions, or how to tie into existing lath, check manufacturer instructions or consult a pro; otherwise plan small test repairs first and work from the edges inward.

Key takeaways

- Inspect soffit framing, control joints, and drainage before any repair.

- Choose crack-resistant stucco mesh and follow mesh layout patterns for durability.

- Prepare materials in clean, dry, shaded area to prevent premature setting.

- Use gravity-rated fasteners correctly per manufacturer instructions and local codes.

- Inspect after cure for cracking, popping, or loose edges and rework.

- Document cost components and project timeline with realistic expectations.

- Wear eye protection, fall protection, and respirators when mixing or spraying.

Table of Contents

- Introduction

- Key takeaways

- Overview and Common Causes of Stucco Soffit Damage

- Tools and Materials Checklist

- Safety Guidelines and Common DIY Hazards

- Diagnosing Soffit Problems and Planning the Repair

- Step-by-Step Repair Process

- Mesh Selection, Layout Patterns, and Fastener Placement

- Material Specs, Codes, and Quality Checkpoints

- Cost Components, Project Timeline, and Case Studies

- Conclusion

- FAQ

Overview and Common Causes of Stucco Soffit Damage

Soffits are the underside of eaves and overhangs; in stucco applications they act as a thin cementitious skin tied to backing, framing, and flashings. Gravity, wind forces, and moisture repeatedly load these areas and expose attachment points and joints to movement that the system must resist.

When soffits fail you commonly see loose panels, sagging, stepped or running cracks, and water entry at joints or degraded flashing—these patterns point to attachment and drainage problems. A basic diagnostic checklist should include substrate soundness, flashing condition, moisture testing behind the stucco, corrosion or looseness of fasteners, and mapping crack directions to infer movement and load paths.

Gravity and structural movement

Soffits, especially those made of stucco, bear the brunt of gravity’s pull. Over time, this constant force can cause panels to sag and detach from their supports.

Inadequate support is a common culprit. If your soffit’s substrate isn’t strong enough or properly secured, it won’t withstand vertical loads for long.

Cracking often follows, as the stucco can no longer expand and contract with temperature changes without stressing its bonds.

Water, freeze-thaw, and biological causes

Moisture entry is a silent killer of soffits. Water can seep behind the stucco, especially where it meets walls or roofs, causing rot in the substrate.

Freeze-thaw cycles exacerbate this issue. When water freezes, it expands, further weakening the structure and creating cracks that let in more moisture.

Pests like termites and carpenter ants can also cause damage by nesting in damp, rotting wood behind your soffit.

Mechanical damage and installation errors

Impact damage from ladders, tools, or falling branches can compromise your soffit’s integrity. Poor fastening during installation is another common mistake.

- Insufficient fasteners: Using too few screws or nails weakens the attachment, leading to detachment and cracking.

- Incorrect spacing: Fasteners spaced too far apart can’t support the stucco properly, causing it to sag and crack.

- Wrong fastener type: Using non-corrosion-resistant fasteners in areas exposed to moisture speeds up failure.

- Poor mesh installation: A base mesh that’s not properly secured or isn’t suitable for the job can’t support the stucco and prevent cracking.

To avoid these mistakes, always use the right number of corrosion-resistant fasteners, space them correctly, and install a suitable mesh according to manufacturer instructions.

Tools and Materials Checklist

Gather hand tools (trowels, hawk, utility knife, shears, pry bar), measuring tools, a level, a caulking gun, and a mixer or drill with a paddle; use power tools only when necessary and follow their safety instructions. For materials, match stucco or cementitious patch products to the substrate and climate, choose crack-resistant mesh compatible with the basecoat, and select weather barriers and sealants rated for exterior use.

Include corrosion-resistant fasteners, appropriate washers, epoxy or mechanical anchors sized for soffit conditions, and a mesh layout plan with spacing guidelines. Don’t forget PPE, scaffold or ladder safety gear, waste-disposal bags, and take quantity measurements (area, thickness, overlap needs) before ordering so you avoid shortages; verify product compatibility on labels or technical datasheets.

Essential tools and access equipment

Before you start, make sure you have all the necessary tools and equipment to ensure a smooth and safe repair process.

- Trowels: For applying and smoothing stucco. Different sizes for different tasks.

- Hawk: Holds material while troweling.

- Cement mixer or drill with paddle: To mix stucco and other materials. Drill with paddle is a DIY-friendly alternative.

- Shears for mesh: To cut lath and mesh to size.

- Measuring tools (tape measure, level): For accurate measurements and ensuring straight lines.

- Pry bar: To remove damaged soffit pieces carefully.

- Caulking gun: For applying sealants around edges and corners.

- Utility knife: For trimming excess material and making clean cuts.

- Power tools (saw, drill) with safety reminders: Use only when needed. Always wear appropriate PPE.

- Ladder or scaffolding: Safe access to soffits is crucial. Ensure it’s stable and secure before climbing.

Quick rule: Never skip safety gear like hard hats, gloves, and eye protection when using power tools or climbing ladders.

Materials: lath, mesh, fasteners, stucco, and sealants

Choose the right materials to ensure a durable, long-lasting repair.

- Lath/mesh: Crack-resistant, galvanized steel or aluminum mesh. Size depends on soffit size and damage extent.

- Fasteners (screws/nails): Corrosion-resistant, suitable for soffit application. Sizes vary based on substrate thickness.

- Washers: To distribute force evenly and prevent stripping.

- Epoxy or mechanical anchors: For securing fasteners into concrete or masonry substrates.

- Stucco (cement-based): Match substrate type (stucco, concrete) and climate for best results. Avoid delamination by matching cementitious products to substrate.

- Adhesives/finish coats: Compatible with chosen stucco. Apply according to manufacturer’s instructions.

- Weather barriers: Breathable or non-breathable, depending on local climate and moisture management needs.

- Sealants: For filling gaps and preventing water intrusion. Choose one compatible with substrate and finish.

Quick rule: Always check compatibility between substrates, mesh, primers, and sealants to avoid failures.

Personal protective equipment (PPE)

Safety first! Protect yourself from dust, debris, and fall risks with the right PPE.

- Gloves: Protect hands from cuts, scrapes, and chemicals. Choose a durable pair that fits well.

- Eye protection (safety glasses or goggles): Shield eyes from dust, debris, and chemical splashes.

- Respirator: Wear when mixing or applying materials with harmful dust particles. Follow manufacturer’s instructions for proper use.

- Hard hat: Protect head from falling objects and bumps while climbing ladders or working at heights.

- Safety harness (for high soffits): Secure yourself to a stable structure to prevent falls. Always follow manufacturer’s instructions.

- Work boots: Provide ankle support, protect feet from falling objects, and provide good grip on ladders or scaffolding.

Quick rule: Never skip PPE. It’s your first line of defense against job-site hazards.

Safety Guidelines and Common DIY Hazards

Work on soffits often involves elevated access; inspect ladders and scaffolds each use and employ guardrails, stable platforms, or harnesses when exposures or heights exceed your comfort or local guidance. Always plan attachment points for fall arrest and keep a safe perimeter below the work area to protect bystanders.

Protect against airborne dust and contaminants with respirators when cutting or sanding, check for lead or asbestos if the house is old, and decontaminate clothing and tools after suspected hazardous-material work. Be careful around electrical lines and wiring—locate conductors, use GFCI protection, and stop work if you find significant rot, pervasive structural cracking, or suspect hazardous materials; those are signs to hire a licensed pro and to document conditions for liability.

Working at Height and Fall Protection

Soffit work means working at heights. Safety starts with the right gear.

Ladders: Use only in good condition, secure footing, and 100% duty rating for your weight plus tools. Keep 3 points of contact at all times.

Scaffolds: Level, plumb, and secure before use. Tie-in with guardrails or harness if over 6 feet high.

Edge awareness is crucial. Stay clear of roof edges. If you must work near edges, use guardrails or a safety harness tied off to a secure anchor point.

Asbestos, Lead, and Testing Precautions

Soffits built before 1980 may contain asbestos or lead. Suspect these if they’re crumbling, damaged, or you see unusual odors.

Before disturbing soffits, get testing: collect samples and send to a certified lab. If results are positive, stop work immediately and hire a certified abatement contractor.

Wear PPE during sampling: respirator, disposable coveralls, gloves, and eye protection. Seal samples in double plastic bags for safe transport.

Hidden Electrical and Plumbing Hazards

Soffits hide wires, pipes, vents. Before cutting or drilling, locate and de-energize: turn off power at the main panel, use a non-contact voltage tester to confirm.

Check for plumbing penetrations too. Turn off water supply valves before working near them.

If you’re unsure about any services, hire a licensed electrician or plumber to locate and protect them before you start work.

Diagnosing Soffit Problems and Planning the Repair

Start with a systematic inspection: look for visible cracking patterns, measure sag, probe for soft wood or delaminated sheathing, and run moisture readings behind suspect areas. Photograph fixed reference points, note seasonal conditions, and mark fastener locations and corroded areas to build your repair plan.

Use your findings to set scope—cosmetic patching versus section replacement or structural reinforcement—and list materials and tools required for the chosen repair path. Prepare sequencing that accounts for weather windows, permit needs, and staged inspections, and include triggers for professional escalation such as significant framing rot or compromised load paths.

Visual Inspection Checklist and Documentation

Before you start any repair work, follow this visual inspection checklist to assess the damage accurately. It’s best to do this on a dry day with good lighting.

- Attachment failure: Check for loose or missing screws, nails, or other fasteners. Look for signs of corrosion or wood rot around them.

- Cracks: Inspect for hairline cracks and larger gaps. Note their width and length.

- Staining: Check for water stains, mold, or mildew, which could indicate moisture issues.

- Deflection: Look for sagging panels or sections that are out of plane with the rest of the soffit. Measure any deflection found.

- Alignment: Ensure doors, windows, and vents align properly with the soffit. Any misalignment could indicate structural issues.

- Fascia and framing: Check for displaced or damaged fascia boards and framing members.

- Seasonal conditions: Note any visible damage that might have been caused by freezing temperatures, snow, ice, or heavy rain.

- Documentation: Take photos from fixed angles to record the condition of the soffit. Include close-ups of cracks, stains, and other defects.

Quick rule: Always document your findings with clear photos and notes. This helps you track progress and ensures you address all issues.

Assessing Gravity Loads and Support Framing

Gravity loads are the forces acting downwards due to the weight of the soffit, lath, and stucco. Evaluate if your framing can handle these loads.

Check: The spacing and size of your support framing members. They should be adequate for the load they’re carrying.

Look for signs of overstress, such as sagging or deflection in the framing. If you find any, consider reinforcing with additional blocking or larger framing members.

Hangers and substrate: Ensure your soffit hangers are securely fastened to the substrate (usually the roof edge). Check for any signs of failure, like pulled-out screws or nails.

Repair Scope and Permit Considerations

Determine the extent of your repair based on the damage found. Small cracks may only need patching, while larger issues might require section replacement.

Permits: Check with your local building department to see if you need a permit for your repairs. Generally, small patch jobs don’t require one, but larger replacements or structural work might.

If in doubt, it’s always best to err on the side of caution and get professional advice. Some cities may also require inspections at certain stages of the repair process.

Safety first: Always prioritize safety over speed. If you’re unsure about any aspect of the repair, consult a professional before proceeding.

Step-by-Step Repair Process

Begin by removing loose or delaminated stucco back to a sound edge and inspect the lathe, backing, and flashing; correct any drainage or framing issues before reapplication. Install the appropriate crack-resistant mesh and secure it to solid backing with corrosion-resistant fasteners following a planned pattern that resists gravity and wind loads.

Build base coats with proper embedment of the mesh, check alignment and embedment before each subsequent coat, and finish with the specified topcoat and sealants. At every stage verify moisture conditions, cure guidelines from the product data sheet, and inspect for early cracking so you can address issues before they require full rework.

Step-by-Step Repair Process

Follow this clear, numbered sequence to repair your soffits safely and effectively. Start with preparation, then do the main work, and finish with cleanup or final checks.

- Preparation: Safety first! Wear PPE, secure your work area, and follow safety guidelines from earlier sections.

- Remove damaged stucco: Use a chisel or reciprocating saw to carefully remove loose, cracked, or crumbling stucco. Keep it clean and safe.

- Inspect substrate/lathe: Check the underlying framing or sheathing for damage. Replace any rotten or weak parts.

- Prepare for reattachment: Ensure the surface is clean, dry, and sound. Prime and apply a moisture barrier if needed.

- Attach lath/mesh: Start from one end, overlap mesh properly (see next step), and use corrosion-resistant fasteners at recommended spacing and depth.

- Apply base coat: Mix stucco according to manufacturer’s instructions, adding bonding agent as needed. Apply evenly over the mesh.

- Finish coats: Apply finish coats following the same process, ensuring each coat is allowed to cure properly before applying the next (see final checks).

- Final checks: Inspect your work for any signs of cracking or unevenness. Make repairs if necessary.

Safe removal and substrate preparation

Remove loose stucco carefully to avoid damage to underlying framing. Inspect and prepare the substrate for reattachment.

Wear safety glasses and gloves when removing stucco. Use a chisel or reciprocating saw to cut along joints, then pry off pieces gently.

Inspect the exposed framing or sheathing. Look for rot, gaps, or other damage. Replace any weak parts with new material.

Prepare the substrate for reattachment: clean it thoroughly to remove dust and debris, prime it to seal the surface and prevent moisture penetration, and apply a moisture barrier if necessary.

Reinforce framing and gravity-safe reattachment

Strengthen your soffit’s backing to ensure fasteners carry load to the structure, not just finish materials.

Check for backing, blocking, or hangers behind the sheathing. If missing or insufficient, install new pieces to provide solid support for fasteners.

Use corrosion-resistant fasteners suitable for your substrate (e.g., screws for wood, nails with washers for metal). Follow recommended spacing and attachment depth guidelines to distribute load evenly.

Ensure fasteners are driven flush or slightly below the surface to avoid interference with lath/mesh application and stucco coats.

Lath/mesh application and stucco finishing

Install lath, embed crack-resistant mesh, apply base and finish coats, and feather joints to minimize future cracking.

Start installing lath from one end of the soffit. Overlap pieces by at least 2 inches for strength. Use corrosion-resistant fasteners at recommended spacing and depth.

Embed crack-resistant mesh in the base coat: Center it over lath, press it firmly into the wet stucco, and ensure it’s fully embedded but not visible on the surface.

Apply base coat: Mix stucco according to manufacturer’s instructions. Add bonding agent if needed. Apply evenly over mesh, ensuring a smooth, level surface. Allow it to cure before applying finish coats.

Apply finish coats: Follow the same process as the base coat. Ensure each coat is feathered into adjacent surfaces and allowed to cure properly (see final checks).

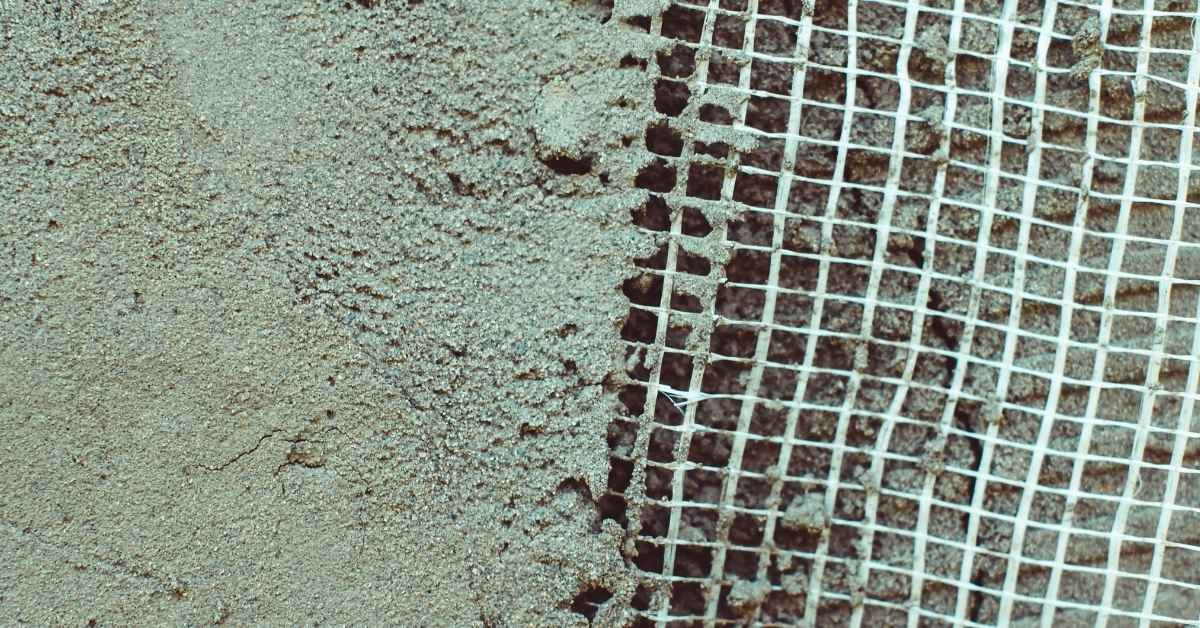

Mesh Selection, Layout Patterns, and Fastener Placement

Choose mesh compatible with the stucco system and substrate—compare glass-fiber, alkali-resistant options, metal, and woven vs non-woven types—and confirm compatibility with your basecoat. Consider mesh elongation and tear resistance where gravity loads and vibration are expected; check manufacturer guidance for approved mesh types.

Lay mesh with consistent overlaps and secure edges to sound backing, using a layout pattern that distributes loads (grid, staggered, or diagonal layouts) and minimizes stress at corners and penetrations. Select corrosion-resistant fasteners sized and spaced for the substrate, anchor into framing or solid backing, and inspect overlaps, edge securement, and fastener pull-through before coating to reduce crack initiation.

Comparing mesh types for durability and ease of use

When it comes to choosing a mesh for your stucco soffits, you’ve got options. Let’s look at the pros and cons of each.

Glass-fiber: Lightweight, flexible, and easy to install. But it’s not as durable as others and can degrade over time with UV exposure.

Alkali-resistant fiberglass: Tougher than glass-fiber, resistant to alkali in cement, and holds up better to weathering. It’s a good balance between durability and ease of use.

Metal (galvanized steel): Strong and durable, it can handle heavy loads. But it’s heavier, harder to install, and can rust if not properly protected.

Mesh layout, overlap, and joint treatment

Laying your mesh right is key to preventing cracks. Here’s how:

Use a 2-4 inch overlap at joints and around corners. This helps distribute stress evenly and prevents cracking.

Position the mesh so it covers control joints. Don’t end the mesh at these joints – that’s where cracks start. Run it right over them.

Treat seams with a crack-resistant compound. Apply it before you lay the mesh to seal any gaps and prevent water intrusion.

Fastener selection and spacing strategy

Securing your mesh right is crucial. Here’s how to choose and place your fasteners:

Go for corrosion-resistant fasteners. Galvanized or stainless steel works best.

Use the right length. It should go through the mesh, lath, and into the structural member – usually 1-1/4 to 2 inches.

Space them out evenly. Aim for about 6-8 inches apart along joists or ledger boards. And never place a fastener where two pieces of mesh meet – that’s a high-stress point.

Material Specs, Codes, and Quality Checkpoints

Confirm product categories before purchase: cementitious stucco mix type, approved reinforcing mesh, lath or backing, corrosion-resistant fasteners, and the specified water-resistive barrier and sealants for exterior use. Cross-check each product’s technical datasheet and local code requirements to ensure materials are permitted and compatible for your climate and substrate.

Maintain a quality checklist during the job: verify substrate suitability, mesh overlap and embedment, fastener spacing, adhesion tests, proper cure conditions, and correct sequencing of barriers and coats. Record product batch numbers, datasheets, and photo logs so you can show compliance and traceability; when in doubt about code or installation specifics, consult the manufacturer instructions or your local building authority.

What to check in manufacturer instructions and local codes

Before you buy materials or start work, review these guides.

- Manufacturer installation manuals: Check for recommended mix ratios, application techniques, and any specific tools needed. Skipping this can lead to subpar results.

- Local building codes: Ensure your repair meets local standards for stucco repairs. Ignoring these can result in costly rework or fines.

- Wind-load provisions: Verify your chosen materials and installation methods can withstand local wind conditions to prevent damage.

- Moisture-management requirements: Check for any specific water-resistive barrier details or drainage needs to prevent moisture issues.

- EIFS-related requirements (if applicable): If your soffits have EIFS, ensure your repair aligns with these standards to maintain system integrity.

- Corrosion resistance: Check fastener and mesh materials for corrosion resistance to prevent early failure.

- Alkali resistance: Ensure cementitious stucco mix is alkali-resistant to avoid degradation over time.

- Crack-control provisions: Review any specific crack-control or expansion joint details relevant to your project.

- Permit requirements: Check if you need permits for the repair. Starting without one can lead to fines and delays.

Quick rule: Always review these guides before starting work to avoid costly mistakes.

Important material properties and testing references

Before selecting materials, check these key properties and test results.

- Cementitious stucco mix: Check for ASTM C926 or similar certifications ensuring the mix meets quality standards. Using uncertified mixes can lead to weak repairs.

- Reinforcing mesh (crack-resistant): Look for ASTM C1653 certification, indicating the mesh meets performance requirements for crack resistance.

- Lath material: Ensure lath is compatible with your chosen stucco mix and can provide adequate support. Using incompatible materials can cause adhesion issues.

- Fastener material and length: Check ASTM C1002 or similar certifications for fasteners, ensuring they meet strength and corrosion resistance requirements.

- Water-resistive barrier details: Ensure the chosen WRB meets local standards and is compatible with your stucco mix. Using incompatible materials can lead to moisture issues.

- Crack-control or expansion provisions: Check for any specific testing or certification requirements related to these provisions.

- Schluter-like drainage or control joints (if needed): Ensure chosen products meet ASTM C1705 or similar standards and are compatible with your repair system.

- Manufacturer datasheets: Review these for detailed product information, including expected performance under various conditions.

Quick rule: Always check these properties and test results to ensure you’re using quality materials.

Visual checkpoints for inspection and sign-off

Use this checklist before signing off on the repair.

- Adhesion: Check that stucco adheres well to the substrate. Poor adhesion can lead to delamination over time.

- Embedment depth: Ensure mesh is fully embedded in the stucco layer. Inadequate embedment can compromise crack resistance.

- Fastener security: Verify fasteners are secure and not protruding, which could cause damage or affect adhesion.

- Finish integrity: Inspect the finished surface for any cracks, voids, or other defects that could indicate underlying issues.

- Cure time: Ensure stucco has cured properly before final inspection. Premature sign-off can lead to premature failure.

- Installation sequence: Check that all layers were installed in the correct sequence, as any deviations could compromise the repair’s integrity.

- Schluter-like drainage or control joints (if needed): Verify these are properly installed and functioning to prevent moisture buildup.

- Environmental constraints: Check that cure conditions were within acceptable ranges. Extreme temperatures or moisture can affect stucco performance.

Quick rule: Always perform a thorough visual inspection before signing off on any repair to ensure quality and longevity.

Cost Components, Project Timeline, and Case Studies

Identify the main cost drivers: materials (stucco mixes, mesh, fasteners, sealants), access equipment (ladders or scaffolding), disposal, and any remediation such as moisture repairs; include a contingency for unanticipated damage. Plan schedule items around inspection, drying and cure times, and likely weather delays when estimating the timeline.

Short case studies help illustrate pitfalls and fixes: a common failure might show bubbling and cracks from poor drainage and improper mesh overlap fixed by reworking flashing and installing correct mesh; a successful repair emphasizes solid anchorage, continuous weather barrier, and correct fastener spacing. For larger jobs get multiple written quotes, compare itemized line items and warranties, and check credentials before deciding whether to DIY or hire a pro.

Cost components and budgeting tips

Repairing stucco soffits can vary greatly in cost. Here’s what drives it:

Materials: Quality matters. Better mesh, fasteners, and sealants mean longer-lasting repairs. Prioritize these.

Access & Labor: Difficult access or complex framing issues bump up labor costs. Consider scaffolding rentals and skilled labor rates.

Factor in a 10-20% contingency for unknowns like hidden damage or weather delays.

Typical project timeline and contractor skill levels

The repair sequence goes: Inspect, assess moisture, repair, cure, coat. Each takes time:

Inspection & Moisture Assessment: 1-2 days. Hire a pro if you’re unsure.

Repair: 3-5 days. Skilled labor is crucial for framing, mesh layout, and stucco application.

Curing & Coating: 2-4 days. Weather delays can occur. Plan accordingly.

Case studies: successful vs. unsuccessful repairs

Unsuccessful Repair: Poor drainage, improper mesh layout led to cracks and bubbles. Fix involved proper mesh placement, reframing gaps, and water management.

Successful Repair: Moisture barrier, correct fastener spacing, and adequate curing time sealed joints and reinforced soffit. Premium materials added cost but ensured durability.

Learn from both: Prioritize moisture management, use quality materials, and follow proper installation techniques.

Conclusion

Protecting your soffits comes down to doing it right, safely, and with a plan that sticks. When you finish, the repairs should look solid, seal well, and stand up to weather without cracking again.

First, run a quick, practical check: inspect the damaged areas, confirm fastener placement and mesh type, verify you’re following the layout pattern, gather the exact tools and materials, test a small area first, plan step by step, keep the work site clean, and allow proper cure time while rechecking against codes and quality checkpoints. Do all of this in that order and document any deviations from the plan.

Two or three common mistakes to avoid are skipping diagnosis and planning, using the wrong fasteners or mesh, and rushing the repair as soon as you see a crack. Do not skip safety tests, never work from a damaged ladder or scaffold, and always handle materials in a controlled way so you don’t introduce new cracks or leaks.

If the damage is extensive, if you’re unsure about fasteners, mesh, or code requirements, or if you uncover hidden water intrusion, call a professional. When in doubt, step back and get a second opinion before you push on. Stay focused, follow your plan, and you’ll finish with a durable, safe soffit that looks right and lasts.

FAQ

What makes stucco soffits different from other soffit materials, and why does that matter for repairs?

Stucco soffits are a plaster-like skin over lath or mesh. They crack and fail when the substrate moves or water gets behind them, so you must repair the cracks and recheck the substrate before finishing.

How do I prepare materials for a stucco soffit repair?

Inspect the area and gather mesh, repair plaster mix or patch options, bonding agents, and finishing coats. Check product labels and follow manufacturer directions for mixing, cure times, and compatibility with existing stucco.

What’s the right approach to fixing cracks in stucco soffits?

Clean out loose material, widen cracks slightly, apply a compatible crack repair product, then embed mesh as directed. Finish with a crack-resistant layer and cure according to the product instructions.

How should I use gravity fasteners and a crack-resistant mesh layout for this repair?

Install fasteners per the product guidelines so they bear load without pulling out. Use a mesh pattern that bridges cracks and ties panels together; space and pattern depend on the product and surface, so follow the label and local guidance. If in doubt, check the manufacturer instructions and local rules before proceeding.