Introduction

A thin concrete overlay over plywood is a lightweight concrete layer applied on a plywood subfloor to smooth and level the surface while staying thin enough to avoid excessive buildup. It must be prepared and reinforced properly to resist cracking in normal use. Check manufacturer instructions and local rules for feasibility and any limits.

Prepare the plywood by cleaning, drying, and making sure it’s firmly anchored before applying anything. Choose a concrete mix rated for overlays and compatible with plywood, and avoid mixes that are too dry or too heavy; always check the label or manufacturer instructions for suitability. Apply the overlay in thin passes, strike off joints, and consider adding reinforcing materials like mesh or fibers as recommended, then allow proper curing.

Key takeaways

- Inspect plywood for moisture, delamination, and fastener pull-out before overlay.

- Choose a compatible thin overlay mix per manufacturer instructions and local rules.

- Prepare plywood surface: clean, sand high spots, and prime if required.

- Use reinforcing materials like mesh or fibers to control cracking.

- Apply in thin, even coats with proper curing and avoid rapid drying.

- Wear safety gear, mask dust, and work area ventilation to prevent hazards.

Table of Contents

- Introduction

- Key takeaways

- Quick Overview: What a Thin Concrete Overlay on Plywood Is and When to Use It

- Tools and Materials Checklist

- Preparing the Plywood Subfloor

- Reinforcement Strategies to Prevent Cracking

- Mixing and Applying the Thin Concrete Overlay

- Installation Step-by-Step Plan and Timing

- Common Mistakes and How to Avoid Them

- Cost, Durability Expectations, and Long-Term Maintenance

- Conclusion

- FAQ

Quick Overview: What a Thin Concrete Overlay on Plywood Is and When to Use It

A thin concrete overlay on plywood is a lightweight layer that sits atop a wood subfloor to create a hard, flat surface. Typical overlays run roughly a quarter to three-eighths of an inch thick. This approach works best for specific project types and finishes.

Use cases include temporary or light-use floors, decorative finishes, or situations where moisture concerns make full subfloor replacement impractical. It’s important to identify the main failure modes early so you know if this method fits your project. Look for bond failures, plywood flexing, moisture-related delamination, and edge lifting at transitions.

Benefits and limitations

A thin concrete overlay on plywood gives you a durable surface that’s ready for tiling or other finishes. It’s like getting a solid concrete floor without the hassle of pouring it all at once.

Pros: It’s quick to apply, compatible with various finishes, and can give your space an industrial look. Plus, it’s lighter than a full concrete pour, making it a good option for upper floors or lightweight structures.

Cons: It’s not suitable for movement-prone substrates. If the plywood moves, cracks, or isn’t properly secured, your overlay will too. Also, while it’s lighter than a full pour, it’s still concrete, so weight can be an issue on certain structures.

Before you start, check local building codes and consult structural engineer if needed. Always ensure your plywood base is secure, level, and has proper compaction. It’s the key to a successful overlay.

Job-site suitability checklist

Before you start, use this checklist to ensure your job site is ready for a thin concrete overlay on plywood. This will help you avoid costly mistakes and ensure a successful project.

- Substrate condition: Check the plywood for any damage or defects. Ensure it’s flat, dry, and structurally sound. (What goes wrong if you skip this: Cracks in your overlay.)

- Moisture level: Test the moisture content of the plywood using a moisture meter. It should be below 12%. (Check manufacturer’s guidelines for specific product requirements.)

- Temperature: Ensure the job site temperature is between 50°F and 90°F (10°C and 32°C). (What goes wrong if you skip this: Poor curing, weak overlay.)

- Humidity: Keep humidity levels below 70%. (Check local weather forecast or use a hygrometer.)

- Traffic load: Consider the intended traffic. Light duty (e.g., residential) is best for thin overlays. (What goes wrong if you skip this: Overlay may not withstand heavy loads.)

- Ventilation: Ensure adequate ventilation to allow proper curing. (Check manufacturer’s guidelines for specific product requirements.)

- Local building codes: Check local codes and obtain any necessary permits before starting work. (What goes wrong if you skip this: Potential fines, rework.)

- Manufacturer’s guidelines: Always follow the manufacturer’s instructions for their specific product. (What goes wrong if you skip this: Overlay may not perform as expected.)

Quick rule: If in doubt, test or check with a professional to ensure your job site is ready for a thin concrete overlay on plywood. This will save you time and money in the long run.

Tools and Materials Checklist

Put together a complete DIY-friendly list of tools, PPE, and materials before you start. Include essential tools, bonding agents, primers, crack fillers, and reinforcement options suitable for thin overlays on plywood. Don’t skip edge treatments and moisture mitigation items if your space demands them.

Also plan substrate prep steps, compatibility checks, and a clear reinforcement strategy. Consider how you’ll handle surface preparation, safe handling, and budgeting so you’re not surprised mid-project.

Reinforcement options and when to use each

Before you start, check these reinforcement options to ensure compatibility with your chosen overlay mix.

- Wire mesh: Ideal for thin overlays (1/4″ – 1/2″). Check aperture size (1/2″ – 5/8″ works best).

- Welded wire fabric: Great for thicker overlays. Ensure it’s compatible with your mix.

- Synthetic fibers: Add to the mix for crack resistance. Check compatibility and dosage.

- Decoupling membranes: Prevent cracking from substrate movement. Ensure they’re suitable for thin overlays.

Quick rule: Always follow manufacturer guidelines for best results.

Concrete mixes and additives

Choose the right mix and additives to minimize cracking in your thin overlay.

- Topping mix: Select a fine aggregate mix (max 1/4″ size) for thin overlays.

- Polymer-modified products: Add polymers like acrylic or vinyl for increased flexural strength. Check compatibility with your chosen reinforcement.

- Bonding agents: Apply a bonding agent to improve adhesion between the overlay and plywood. Follow manufacturer instructions.

- Crack-reducing admixtures: Add air-entraining or shrinkage-compensating admixtures to reduce cracking. Follow manufacturer guidelines for dosage.

Quick rule: Always follow manufacturer mix ratios and specs for best results.

Essential tools and safety gear

Gather these tools and safety gear before starting your project to ensure a smooth process.

- Mixer: A portable mixer (electric or gas) is essential for mixing small batches.

- Trowels & screeds: Trowels (1/4″ – 3/8″) and screeds are needed for applying and leveling the overlay.

- Fasteners: Screws or nails to secure plywood edges. Use corrosion-resistant ones if exposed to moisture.

- Respirator: Protect yourself from dust with a NIOSH-approved respirator.

- Gloves & knee protection: Wear gloves for handling materials and knee pads for comfort during application.

- Safety glasses: Protect your eyes from debris with ANSI-approved safety glasses.

- Hearing protection: Use earplugs or earmuffs when using power tools like mixers or saws.

Quick rule: Always prioritize safety and follow manufacturer guidelines for tool usage.

Preparing the Plywood Subfloor

Assess the current plywood condition with a critical eye for delamination, soft spots, water damage, or loose panels. Confirm panels are rated for structural use and are properly fastened before proceeding. A solid base makes the rest of the work easier.

Flatness and movement must be addressed. Use a straightedge or level to spot high and low spots, then re-fastens or sand to achieve a uniform surface. Plan for a moisture barrier and bonding readiness as you prepare the substrate.

Inspecting and repairing the subfloor

Start by checking every square foot of your plywood subfloor. Look for:

- Rot: Soft, crumbly wood means trouble.

- Delamination: Layers separating? That’s bad news.

- Deflection: Bounce on it. If it gives, sister a new panel over it.

- Loose or missing fasteners: Tighten screws/nails, replace if needed.

If you find issues, replace or sister panels. Don’t skip this step!

Stiffening and fastening strategies

To reduce deflection:

- Add screws/nails: If they’re missing or loose, add more.

- Install blocking: Between joists for extra support.

- Add layers: Sister new plywood over weak spots.

Remember: Consult structural guidelines for load limits. Don’t guess, check!

Cleaning and priming for best bond

Thorough cleaning is key:

- Remove dust: Vacuum, then wipe with a damp cloth.

- Degrease: Use a suitable cleaner to remove oils and grease.

Then, prime or use a bonding slurry:

- Follow product instructions: Don’t skip steps!

- Allow proper dry time: Patience pays off here.

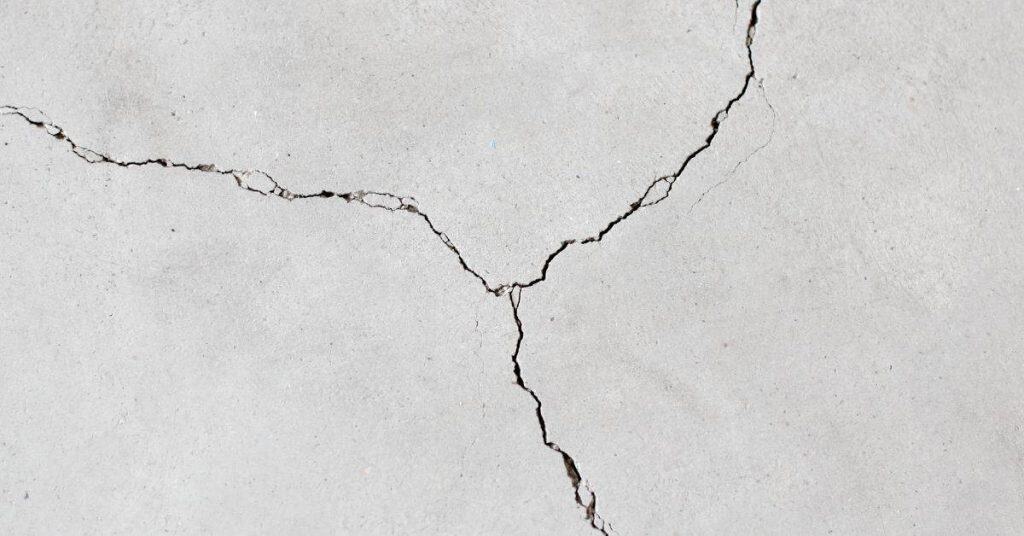

Reinforcement Strategies to Prevent Cracking

Gather reinforcement options suitable for a thin overlay on plywood, such as welded wire mesh, fiberglass or steel fibers, wire or rebar grids, and crack-bridging additives. Each option has implications for moisture exposure, workability, and final crack resistance. Compare pros and cons to fit your paneling and traffic expectations.

Define a practical placement sequence that minimizes voids and trapped moisture. Debond the surface if needed, address moisture targets, lay reinforcement, and then pour with proper compaction and finish. Follow product guidance to keep membranes from wrinkling and ensure continuity at transitions.

Mesh and Welded-Wire Reinforcement

For thin concrete overlays, use 1/2″ to 5/8″ mesh or welded wire. They provide stiffness and crack resistance.

Positioning: Place the mesh within the overlay thickness – not at the bottom. This keeps it from creating stress points where cracks can start.

Securing: Use snap ties to secure the mesh to the plywood. Stagger them for even support. Avoid over-tightening, which can create stress points.

Fiber Reinforcement vs. Traditional Metal

Synthetic fibers and steel fibers both control shrinkage cracks but differ in impact on finishing and cost.

Synthetic Fibers: These are cheaper, lighter, and easier to handle. They don’t corrode like steel. However, they may not provide the same stiffness as metal.

Steel Fibers: Steel provides more strength and stiffness but is heavier, pricier, and can rust if not properly protected. It’s ideal for thicker overlays or high-traffic areas.

Isolation and Decoupling Membranes

Membranes like polyethylene or polyolefin sheets isolate the overlay from substrate movement, preventing cracks.

Materials: Choose a membrane that’s durable, flexible, and resistant to chemicals. Thickness should be around 6-10 mils.

Installation: Lay the membrane on the prepared plywood before installing reinforcement. Ensure it overlaps at seams by at least 4 inches. Cut slits for fasteners without puncturing the membrane.

Mixing and Applying the Thin Concrete Overlay

Start with substrate prep and compatibility checks: ensure sound plywood, sand high spots, and keep moisture below dew point thresholds. Clean the surface and seal with a bonding agent to improve adhesion and reduce outgassing during cure. A solid bond begins here.

Focus on mix design and consistency, batch-to-batch uniformity, and a workable slump suitable for troweling. Mix dry components first, then add water gradually and avoid air entrainment. Maintain a cohesive batch for even placement and strong bonding.

Choosing mix consistency and water control

For a thin concrete overlay, you want a workable mix that won’t crack. Start with the right cement type – Type I or II for most overlays.

Sand gradation is crucial. Use clean, well-graded sand, not too fine nor too coarse. Aim for a water-cement ratio around 0.45 to 0.55 for workability without excess water.

Check slump guidelines from your cement manufacturer. You want a ‘stiff’ consistency, around 1-2 inches of slump. Use admixtures like superplasticizers or viscosity modifiers to improve workability with less water.

Applying, screeding, and finishing techniques

Start by applying a thin tack coat of your mix onto the primed plywood. This promotes bonding.

Lay the overlay in uniform passes using a trowel or notched spreader. Screed off excess material with a straight edge to maintain consistent thickness – around 1/4″ to 3/8″.

Float the surface with a steel trowel to smooth it out and consolidate the concrete. Be careful not to overwork the overlay, which can lead to excessive water loss and cracking.

Bonding layers and feathering edges

Use a bonding slurry or primer for your initial coats. This improves adhesion between the overlay and the plywood substrate.

When feathering overlays into existing surfaces, use a softening-off technique to prevent stress risers. Gradually reduce trowel pressure as you approach the edge, creating a smooth transition.

Don’t pull away from the substrate with excessive trowel pressure. This can create weak points that may crack under stress.

Installation Step-by-Step Plan and Timing

Define the sequence from substrate prep to moisture barriers, reinforcement, formwork, pour, and cure. Map out a realistic timeline that accounts for temperature and humidity considerations. This plan keeps the project orderly from start to finish.

Check plywood thickness and condition, moisture content, and reinforcement details as you go. Outline pour size limits and rest periods, and plan edge detailing to prevent movement issues. A clear plan reduces surprises on the jobsite.

Step-by-Step Installation Process

The following is a clear, numbered sequence of practical steps for your thin concrete overlay installation. It starts with preparation and safety checks, moves on to the main work, and ends with final checks.

- Inspect and prepare your plywood subfloor as detailed earlier.

- Lay out your moisture barrier or epoxy primer, ensuring full coverage.

- Plan and lay your reinforcement. For mesh, secure it every 4-6 inches; for fibers, distribute evenly.

- Set up your slab formwork and edge detailing, ensuring proper alignment with control joints.

- Mix your concrete according to the target strength and slump, batching in manageable sections. Pour, screed, bull float, and finish as per recommended techniques.

- Check for levelness and correct any issues immediately.

- Let it cure for at least 24 hours before walking on it lightly. Recheck for cracks after 7 days.

- If all is well, proceed with your flooring installation or final finishing touches.

Layout, Thickness Planning, and Control Joints

The overlay’s success relies on proper planning of its thickness and joint layout. Here’s how to do it:

Thickness Planning: Aim for 1/2″ to 3/4″ thick overlays. Thinner than 1/2″ risks cracking, thicker than 3/4″ may require additional reinforcement.

Control Joints: Place them every 6-8 feet, aligned with substrate seams to control where cracks will form. Use a straight edge and pencil for accurate marking.

Edge Details: Ensure edges are properly supported and reinforced to prevent spalling or delamination.

Laying Reinforcement and Pouring Sequence

Proper placement of reinforcement is key to preventing cracks. Here’s how:

Maintain a consistent cover of 1-2 inches over your reinforcement. This protects it from corrosion and ensures proper bond with the concrete.

Work in manageable sections, ensuring continuous bond without cold joints. Overlap mesh by at least 6 inches and secure properly to maintain continuity.

Pour your concrete in small batches, working from one side of the room to the other. Keep your pours within 24 hours apart to avoid cold joints.

Curing, Protection, and Traffic Timelines

Proper curing is crucial for the strength and longevity of your concrete overlay. Here are some best practices:

Keep the surface moist using a fine mist or plastic sheeting for at least 7 days. Follow your product’s specific cure schedule.

Protect the surface from heavy traffic, sharp objects, and extreme temperatures until fully cured. Use caution signs to keep others away.

Traffic Timelines: Light foot traffic can usually resume after 24 hours. Heavy traffic or moving furniture should wait at least 7 days. Always recheck for cracks before resuming normal use.

Common Mistakes and How to Avoid Them

Substrate and thickness checks are critical. Verify plywood condition, moisture, and full surface contact before applying the overlay. Patch or replace problem areas to maintain a uniform plane. A careful assessment prevents future cracks.

Bonding system pitfalls often derail a project. Avoid plain concrete on plywood and follow proper primers or epoxy treatments. Conduct adhesion tests and document bond strength to guide your approach.

Too-thin overlay or insufficient stiffening

Plywood is flexible. A thin concrete overlay on it can crack easily, especially with foot traffic or weight.

Rule of thumb: For every 1/8″ of plywood thickness, add at least 1/4″ of concrete. So, if you’ve got 1/2″ plywood, you need a minimum 3/4″ overlay.

Too thin or flexible, and your overlay will crack like an eggshell under stress.

If your overlay’s too thin, consider adding more concrete. Or, stiffen the substrate with additional layers of plywood, or use a rigid foam board underneath.

Poor bonding and trapped moisture

Concrete needs a good bond to stay put. If it’s peeling off or cracking, something went wrong.

Check for contaminants on the plywood – dirt, grease, or old paint can stop concrete from sticking. Remove them before applying any bonding agent.

Moisture’s another culprit. Too much can make your overlay crack as it dries. Use a moisture meter to check your plywood. If it’s over 12%, consider sealing the subfloor with a vapor barrier or letting it dry out more.

Before applying the overlay, do an adhesion test. Apply some bonding agent and let it cure. Then, try to scrape it off. If it peels easily, re-prep your surface.

Skipping joints, reinforcement misplacement, or improper curing

Control joints help concrete crack where you want it to, not where it wants to. Skip them, and your overlay will find its own way to release stress – usually by cracking unpredictably.

Reinforcement needs to be placed correctly too. If it’s too close to the surface or not evenly distributed, it won’t support your overlay properly. Follow your design plan for placement.

Proper curing is crucial. Concrete needs moisture and time to gain strength. Don’t rush it by exposing it to wind or sun too soon. Keep it moist-cured for at least 7 days, using a plastic sheet or curing compound if needed.

Cost, Durability Expectations, and Long-Term Maintenance

Outline the main cost drivers for a thin overlay, including material choices, thickness targets, surface prep, moisture mitigation, fasteners, adhesives, and labor. Use a framework to estimate regional costs and build a basic bill of materials. This helps with budgeting and comparison shopping.

Set durability expectations by linking thickness, prep quality, mix type, and reinforcement strategy to wear resistance and crack control. Create a practical maintenance plan with routine inspections and resealing or repair steps to extend life.

Cost breakdown and budgeting tips

The main cost drivers for a thin concrete overlay over plywood are materials, tools/rental, and labor if hired.

Materials: Concrete mix (around $100-$200 per 80 sq ft), reinforcement mesh ($5-$15 per 4×8 sheet), fasteners/adhesives ($30-$60), plywood if needed ($20-$50 per 4×8 sheet).

Tools/Rental: Mixer ($40-$70/day), screed ($10-$20/day), trowel ($5-$15 each), and other basic tools. Check local prices and supplier quotes for accurate budgeting.

Inspection, repair, and refinishing over time

Regularly inspect your concrete overlay to maintain its longevity. Use this checklist every 6-12 months.

- Hairline cracks: Check for fine cracks using a flashlight. Seal with a crack filler if found.

- Delamination: Tap the surface with a hammer. A dull thud indicates delamination. Reattach using construction adhesive and reinforce.

- Wear: Inspect edges and high-traffic areas for wear. Touch up with concrete resurfacer if needed.

- Moisture testing: Check plywood moisture levels to prevent future issues. Use a moisture meter (around $50).

Quick rule: Address minor issues promptly to prevent major repairs or replacement.

When to choose alternatives

While thin concrete overlays are versatile, they’re not always the best long-term solution. Consider these scenarios:

Structural issues: If your subfloor has significant damage or isn’t level, consider full structural remediation before overlaying.

Moisture problems: If you have persistent moisture issues, install a cement backer board system instead to prevent future delamination and mold growth.

Limited access or time: Sleeper systems might be better if you need quick installation with minimal disruption. They’re also ideal for hard-to-reach areas like under staircases.

Conclusion

Finishing a thin concrete overlay over plywood can give you a durable, good-looking floor if you respect the basics of prep, reinforcement, and cure. The key is to keep safety at the top of the plan and to verify the substrate and mix are treated correctly before any full-area work.

Start by verifying the subfloor is sound, clean, and dry; then confirm the plywood is secured and free of loose edges, reinforce as planned, mix and apply the overlay to the recommended thickness, and cure with proper ventilation before testing a small area to ensure there are no cracks or delaminations. Safety first means wearing eye and respiratory protection, following the product directions, and keeping bystanders clear during mixing and curing.

Common mistakes to avoid include skipping moisture checks, under- or over-reinforcing, and rushing the cure or misreading the mixing ratios. A simple rule is to test a small patch first, respect the cure time, and never apply the overlay when the substrate is damp or when conditions are outside the recommended range. If the project scope feels beyond your experience, or if the subfloor shows significant damage, call a professional so you don’t risk costly cracks or a failed installation. Stay disciplined, stay patient, and you’ll end up with a solid, durable surface that looks right and performs well.

FAQ

What should I do to prepare the plywood surface before applying a thin concrete overlay?

Make sure the plywood is clean, dry, and free of dust, oil, and loose paint. Sand any high spots and fix loose edges or gaps with patches. Check the substrate for moisture and repair or replace any rotten panels per the substrate manufacturer’s guidance.

How do I choose an appropriate mix for a thin overlay on plywood?

Select a mix rated for thin overlays and compatible with plywood substrates. Read the label for recommended thickness, cure time, and any required additives. If in doubt, consult the product instructions or ask the supplier for options suited to wood substrates.

What are practical techniques for applying a thin concrete overlay over plywood?

Apply in thin, even passes and avoid dumping large amounts at once. Use a gauge rake or smoother to level the surface and keep the thickness uniform. Work in small sections to maintain control and prevent early-set seams that can crack.

Should I add reinforcing materials like mesh or fiber, and how do I cure properly?

Reinforcement helps control cracking on plywood. Use mesh or fiber per the overlay product’s guidance and embed it correctly in the first few coats. Keep the surface protected from rapid drying and moisture swings; follow product instructions for curing times and ventilation. If you’re unsure, check the label or manufacturer instructions and local moisture guidelines.