Introduction

Tackling concrete surface laitance requires a strategic approach that involves careful timing. From spotting the issue to removing it and preventing its recurrence, understanding the timeline is crucial for successful DIY management.

This guide walks you through each stage of dealing with laitance, ensuring you allocate sufficient time for each task and maintain a smooth workflow.

For the full guide, see Concrete Surface Laitance: How to Spot It, Remove It, and Prevent It Next Time.

Understanding the Timeline for Laitance Management

The timeline for managing concrete surface laitance can be broken down into three main phases: spotting, removing, and preventing. Each phase requires careful planning and allocation of time to ensure optimal results.

- Spotting (Day 1-3): Inspect the concrete surface within the first few days after pouring to identify any signs of laitance. This involves visual checks and simple tests like scratching or rubbing the surface with a gloved hand or broom.

- Removal (Day 3-7): Once laitance is spotted, remove it promptly to prevent further weakening of the concrete surface. The removal process can take anywhere from a few hours to several days, depending on the severity and extent of the laitance and the chosen method (mechanical or chemical).

- Prevention (Day 7 onwards): After removing laitance, focus on preventing its recurrence by adopting best practices during mix design, placement, finishing, and curing. These preventive measures should be implemented from day 7 onwards to ensure long-term durability and adhesion of the concrete surface.

By understanding and adhering to this timeline, home DIYers can effectively manage concrete surface laitance and maintain a strong, durable concrete surface.

Key takeaways

The time spent on preparing the concrete surface for removal directly impacts the overall schedule. Ensure you allocate sufficient time for each step to avoid rushing through the process and compromising the final result.

- Recognize laitance as a weak, top surface skim with fines and cement.

- Inspect blotchy sheen and powdery feel before finishing to decide removal.

- Remove laitance with mechanical abrasion or chemical cleaner following label instructions.

- Test by performing a water drop test after cleaning to confirm porosity.

- Prevent by using proper slump, timing, and finish technique suitable for environment.

- Wear eye protection, gloves, and watch for dust during removal and cleanup.

Table of Contents

- Introduction

- Key takeaways

- What Is Concrete Surface Laitance?

- How to Spot and Diagnose Laitance

- Causes and Contributing Factors

- Risks and Why You Should Care

- How to Remove Laitance: Methods and Step-by-Step

- Tools and Materials Checklist

- Preventing Laitance Next Time: Best Practices for Mix, Placement, and Finishing

- Aftercare, Inspection, and Preparing for Coatings or Overlays

- Conclusion

- FAQ

What Is Concrete Surface Laitance?

Laitance is the weak, powdery film that can form on the top of fresh concrete when fines and excess cement rise to the surface during placement and finishing. It’s a loose layer that can be scraped or brushed off, unlike properly consolidated concrete.

Don’t confuse laitance with efflorescence or ordinary dust: efflorescence is a crystalline salt deposit that typically dissolves with water, and dust is loose dirt; check product data sheets or lab guidance if you need help distinguishing them.

Technical definition and formation process

Laitance is a weak, powdery layer that forms on the surface of concrete. It’s mainly made up of cement and fine particles.

Here’s how it happens:

Bleeding – When water rises to the surface during concrete setting, it carries fine particles with it. These particles concentrate at the surface as the water evaporates. If finishing is done too early, these particles can’t bind properly and form laitance.

Common misconceptions

Laitance often gets confused with other surface issues:

Surface contamination – Unlike laitance, this is usually dirt or debris that can be easily washed off. Laitance requires more than just cleaning.

Curing residue – Curing compounds leave a thin film, not a powdery layer like laitance. They also don’t flake off like laitance does.

Wear and tear – This happens over time due to use or weathering. Laitance appears soon after concrete placement if not removed.

How to Spot and Diagnose Laitance

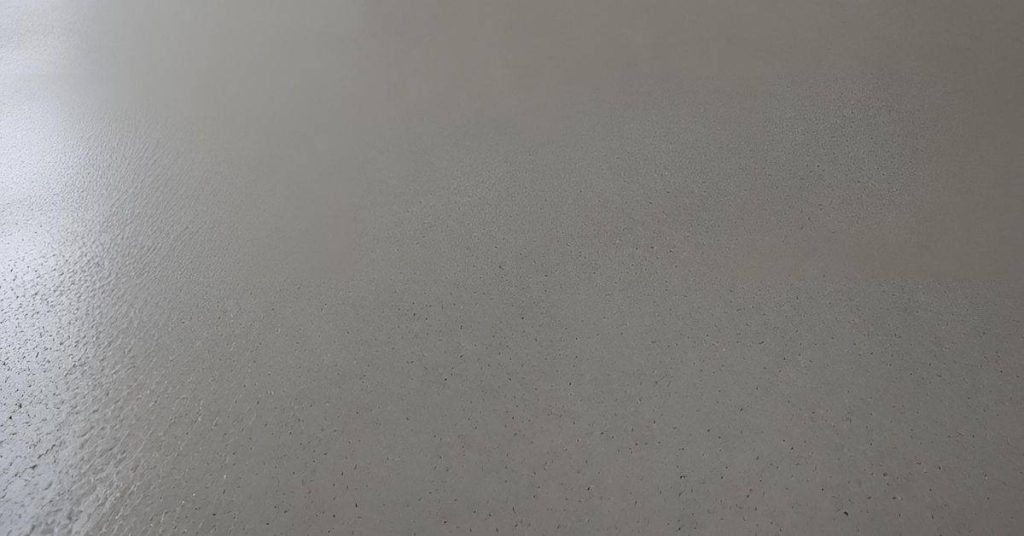

Look for a chalky, powdery surface that smears or rubs off when you press with a gloved finger or scratch with a screwdriver; it may also appear lighter in color than the surrounding concrete. Laitance will often produce a fine powder when swept or brushed and may flake off in thin layers.

On-site checks include a simple scratch test and a water spot test to see if the surface absorbs or beads; when in doubt, follow manufacturer instructions or send a sample to a lab for confirmation.

Step-by-Step Process

Follow these practical steps to spot and diagnose laitance on your concrete surface.

- Prepare the area: Clear debris, wear safety gear (gloves, goggles).

- Inspect visually: Look for powdery sheen, color changes, surface powder.

- Rub with a cloth: Feel for loose material. If it rubs off easily, laitance is present.

- Check water absorption: Pour water on the surface. Laitance may cause slower absorption or beads forming.

- Perform adhesion test: Gently scratch the surface with a coin or screwdriver. Laitance feels soft and comes off easily.

Visual checkpoints and photos to look for

Use this checklist when inspecting your concrete surface for laitance.

- Powdery sheen: Laitance gives a whitish, powdery appearance under sunlight or artificial light.

- Color changes: Discoloration or uneven coloring can indicate laitance presence.

- Surface powder: Gently rub the surface with a damp cloth. If it leaves behind a white residue, laitance is present.

- Uneven texture: Laitance causes an inconsistent, rough feel on the surface.

Quick rule: Always take photos of suspected laitance areas for records and future reference.

Simple field tests and probe methods

These quick tests help diagnose laitance on your concrete surface:

Rubbing with a cloth: Gently rub the surface with a damp cloth. If it leaves behind a white residue, laitance is present.

Water absorption observation: Pour water on the surface. Laitance may cause slower absorption or beads forming, indicating weak surface layer.

Adhesion checks: Gently scratch the surface with a coin or screwdriver. If the material feels soft and comes off easily, laitance is present.

When to perform lab or professional testing

Before coatings or structural repairs, consider sending samples for lab analysis or performing adhesion/strength tests:

Lab analysis: Ask the lab for laitance content, compressive strength, and water-cement ratio. This helps determine the severity of the laitance issue.

Adhesion/strength tests: These help assess the concrete’s bond strength and overall integrity before applying coatings or making repairs.

Causes and Contributing Factors

Common causes are mix design with too many fines, adding too much water at the site, and overworking the surface during finishing—each action brings fines and cement to the top and reduces surface strength. Inadequate curing and adverse weather (wind, heat, rain) further prevent proper hydration and lock a weak film onto the surface.

Consider each pour phase when diagnosing causes, and if specifics matter for your project, check the mix ticket, product labels, or manufacturer guidance for recommended procedures and limits.

Mix and material-related causes

The mix design and materials used can significantly impact the formation of laitance on your concrete surface.

- High water-cement ratio: Too much water weakens the cement paste, causing it to rise to the surface. Specify a water-cement ratio of 0.45 or less.

- Excess fines: Fine particles can clog the pores and prevent proper curing. Avoid aggregates with more than 10% passing the #200 sieve.

- Poorly graded aggregates: Incorrect grading can lead to improper packing, allowing water to rise. Use well-graded aggregates following ASTM C33 standards.

- Inadequate cement content: Low cement content weakens the paste, promoting laitance. Ensure a minimum cement content of 200 kg/m³.

- Poorly designed mix: An improper mix design can lead to excessive bleeding and laitance. Consult with a concrete technologist for proper mix designs.

Placement, finishing, and curing mistakes

Premature finishing, excessive troweling, and improper curing can create a weak surface layer prone to laitance.

- Premature finishing: Finishing concrete too early prevents proper hydration. Avoid finishing until the initial set is complete (about 3-6 hours).

- Excessive troweling: Overworking the surface brings weak cement paste to the top. Limit troweling time and use appropriate tools.

- Drying out during early stages: Early drying prevents proper curing, leading to laitance. Keep concrete moist for at least 7 days after placement.

- Improper finishing techniques: Incorrect use of tools can cause laitance. Use appropriate tools and techniques based on the finish desired.

Proper placement, finishing, and curing are crucial to prevent laitance. Follow best practices for your specific project.

Environmental factors and timing

The weather conditions during concrete placement can significantly impact the formation of laitance.

High temperatures: Hot weather speeds up hydration, causing excessive bleeding and laitance. Consider placing concrete early in the morning or late in the evening to avoid peak temperatures.

Wind: Strong winds can cause rapid evaporation of water from the surface, leading to laitance. Protect the concrete from wind using barriers or windbreaks.

Rain: Rainfall during early stages can wash away cement paste and cause laitance. Cover the concrete with plastic sheeting if rain is expected.

Risks and Why You Should Care

Laitance undermines surface performance: coatings and overlays may not bond properly, surface wear can accelerate, and the area becomes more susceptible to scaling and abrasion. Even small projects like driveways or steps can have shortened service life or require premature repairs if laitance is left in place.

Before proceeding with finishing or coating, verify surface suitability per the coating or overlay manufacturer’s instructions and address laitance to avoid adhesion failures and durability problems.

Coating and adhesive failures

Laitance is a weak layer on your concrete surface. It doesn’t stick well to itself, let alone anything you apply on top. This means any coatings or adhesives you use – like paint, sealers, or overlays – won’t bond properly.

Think of it like trying to glue two pieces of wet paper together. They won’t stick. Same goes for laitance and your coatings. That’s why surface prep standards demand you remove it before applying anything.

Result? Your coatings will peel, flake, or delaminate over time. You’ll be left with a mess and have to start all over again.

Long-term durability and safety impacts

Laitance might look like a harmless, thin layer. But it can hide or accelerate surface deterioration. Here’s why:

Water gets trapped under laitance. It can’t evaporate properly during curing. This leads to delayed ettringite formation (DEF), which weakens your concrete over time.

Moreover, laitance can hide cracks and other defects. You won’t see them until it’s too late – when they’ve grown bigger or caused more damage.

Safety alert! Hidden cracks can compromise the structural integrity of your concrete. It could lead to unexpected failures, putting people at risk.

How to Remove Laitance: Methods and Step-by-Step

Begin with low-impact methods—stiff brushing, pressure washing, and mild acid etching—then progress to mechanical abrasion like grinders or shot blasting for stubborn or thick laitance. Each method has trade-offs: gentler techniques preserve profile but may not remove all material, while aggressive techniques remove more but need more skill and PPE.

Follow a stepwise plan: test a small area first, consult product labels or manufacturer instructions for cleaning agents and equipment settings, and only scale up to heavier methods if the test area shows acceptable results.

Step-by-Step Cleaning Process

Follow these steps to remove laitance from your concrete surface safely and effectively.

- Preparation: Put on safety gear – gloves, goggles, and a dust mask. Tape off any areas you don’t want affected.

- Dampen the area: Use a garden hose or spray bottle to lightly wet the surface. This helps control dust and prevents laitance from spreading.

- Scrubbing: Use a stiff-bristled broom, brush, or scrubber to agitate the laitance. Work in small sections at a time.

- Check progress: Inspect your work frequently. Laitance should start lifting off. If not, you may need to use a stronger method.

- Rinse and repeat: Rinse the area thoroughly with clean water. Let it dry, then re-inspect. Repeat if necessary.

- Final check: Once laitance is removed, perform a final inspection. If any spots remain, target them specifically.

Light-duty DIY removal (scrubbing, detergent, pressure washing)

For minor laitance issues, soap and water or a mild alkaline cleaner can do the trick. Pressure washing can help with stubborn spots.

Soap/Alkaline Cleaners: Mix a few drops of dish soap or an alkaline cleaner into a bucket of warm water. Dip a stiff-bristled brush in, then scrub the laitance. Work in small sections to avoid drying out.

Pressure Washing: Use a pressure washer with a wide-angle nozzle (at least 40°). Start at a low setting and work your way up if needed. Keep the wand moving to prevent damaging the surface.

Remember, these methods are best for light laitance. If it’s thick or stubborn, you may need heavier-duty equipment.

Mechanical removal (grinding, shot blasting, sanding)

For tough laitance, you’ll need heavy-duty equipment. Here’s what to use and how:

Grinders/Sanders: Use a concrete grinder or sander with coarse discs. Work in small sections, keeping the machine level and moving at a steady pace.

Shot Blasting: This method uses high-velocity steel shot to blast away laitance. It’s fast but can be messy and damaging if not done right. Always wear protective gear and contain the area.

Safety is key with these methods. Wear appropriate PPE, keep the area contained, and work in a well-ventilated space.

Chemical removal (acid etching, commercial strippers)

Chemical methods can dissolve laitance but require careful handling. Here’s how to use them:

Acid Etching: Apply a mixture of muriatic acid and water (follow the manufacturer’s instructions) to the surface. Let it sit, then scrub with a stiff-bristled brush. Rinse thoroughly and neutralize with a base like baking soda.

Commercial Strippers: These are available at hardware stores. Follow the package instructions for application, dwell time, and neutralization.

Always wear appropriate PPE when handling chemicals. Ventilate the area and keep pets and children away until the surface is completely neutralized and rinsed.

Tools and Materials Checklist

Gather basic hand tools—stiff-bristle brooms, wire brushes, scrapers—and PPE such as N95 or higher respirators, eye protection, gloves, and knee protection for manual work. For heavier removal, plan for rented equipment like pressure washers, planetary grinders, or shot blasters and include dust-control gear and containment materials.

Choose cleaning agents and abrasives according to product instructions and the surface condition; if you’re unsure which chemical or abrasive to use, check the manufacturer data sheet or consult a rental house for recommended options and safe use guidance.

Personal protective equipment and safety gear

Before starting any concrete work, ensure you have the right PPE to protect yourself from dust, chemicals, and noise. Use this checklist every time you’re on site.

- Respirator: Check it fits properly and filters out particles (PM10 or PM2.5).

What goes wrong if you skip: Inhaling silica dust can cause lung disease. - Safety glasses: Ensure they protect your eyes from impact and debris.

What goes wrong if you skip: Eye injuries can lead to permanent damage. - Earplugs or earmuffs: Check they reduce noise levels below 85 dB(A).

What goes wrong if you skip: Prolonged exposure to loud noises can cause hearing loss. - Gloves: Ensure they protect your hands from cuts, burns, and chemicals.

What goes wrong if you skip: Hand injuries can affect your ability to work. - Steel-toed boots: Check they protect your feet from heavy objects.

What goes wrong if you skip: Foot injuries can be severe and require immediate medical attention. - Hard hat: Ensure it’s undamaged and fits properly to protect against head injuries.

What goes wrong if you skip: Head injuries can be life-threatening. - Work clothes: Check they’re long-sleeved, long-legged, and cover your skin.

What goes wrong if you skip: Concrete splashes can cause severe burns.

Quick rule: Always wear PPE when working with concrete. If it’s hot or dusty, take breaks to cool down and hydrate.

Recommended tools and rental options

Before you start your concrete surface preparation project, use this checklist to ensure you have the right tools for the job. This will help you avoid common mistakes and save time and money.

- Pressure Washer (2000-3000 PSI): Check that it has a suitable detergent tank and a surface cleaner attachment to effectively clean large areas.

- Surface Cleaner Attachment: Ensure it’s the right size for your project, typically 15″ – 20″ for most residential jobs.

- Concrete Grinder (4″ – 6″): Verify it has variable speed control and a vacuum port to collect dust.

- Diamond Cup Wheels: Check they match your grinder’s size and have the correct grit for your project (e.g., 30/60 for light grinding, 120/160 for heavy duty).

- Shot Blaster or Scarifier (optional): If dealing with heavy concrete buildup, check if you need to rent one. Ensure it’s suitable for your surface area and condition.

- Concrete Sealer: Confirm you have the right type (e.g., acrylic, silane, or epoxy) based on your project requirements and local climate.

- Safety Equipment: Briefly refer to our earlier section for a reminder on necessary PPE, including safety glasses, hearing protection, gloves, and a dust mask/respirator.

- Tape Measure & Level: Always have these on hand to ensure accurate measurements and proper application of sealers or other materials.

Quick rule: Match your tool size to the job scope. Larger tools aren’t always better; they can cause damage if not used correctly for smaller projects.

Cleaning agents, neutralizers, and consumables

Before you start any concrete work, make sure you have the right cleaning agents, neutralizers, and consumables on hand. This checklist will help you prepare.

- Concrete Cleaner: Check that it’s designed for your specific type of concrete (e.g., plain, colored, stamped). Confirm it by reading the product label.

- Acid Neutralizer: Have one if you’re using acidic cleaners. Verify its compatibility with the acid cleaner you’re using by checking the manufacturer’s instructions.

- Disposable Gloves: Check for proper sizing and material (latex or nitrile) that’s compatible with your cleaning agents.

- Safety Glasses: Ensure they meet ANSI Z87.1 standards for eye protection. Look for the ‘Z87’ marking on the lens.

- Respirator Mask: If using strong chemicals, check it fits well and filters out harmful particles or gases (check manufacturer’s instructions).

- Scrub Brushes: Have stiff-bristled brushes for tough cleaning jobs. Check bristles are secure before use.

- Sponge or Chamois: For applying and removing cleaners. Check they’re in good condition with no tears.

- Trash Bags: Have heavy-duty bags for disposing of cleaning waste. Check they can handle the weight and volume of your waste.

Quick rule: Always follow manufacturer instructions when using cleaners, neutralizers, and safety gear to avoid injuries or damage.

Preventing Laitance Next Time: Best Practices for Mix, Placement, and Finishing

Preventive steps start at mix design—specify appropriate aggregate gradation and limit unnecessary fines—then control water at the jobsite to avoid overly wet mixes. During placement and finishing, avoid overworking the surface and protect curing concrete from rapid drying or rain with proper curing compounds or wet covers.

Plan the pour sequence, review batching records, and follow manufacturer or project specifications for finishing and curing; when in doubt about a product or method, check the supplier’s technical guidance or local rules before you pour.

Mix design and material selection tips

Choosing the right materials for your concrete mix can significantly reduce laitance. Here’s what to consider:

- Water content: Too much water makes concrete soupy, increasing surface fines. Ask your supplier for a water-cement ratio around 0.45.

- Admixtures: Air-entraining agents can help reduce laitance by creating tiny air bubbles that push fines to the surface during bleeding. Specify this in your mix design.

- Cement type: Type I or II cement is standard for most projects. Avoid Type III, which sets too fast and increases laitance risk.

- Aggregate grading: Well-graded aggregates (clean, angular) reduce fines. Ask for a grading chart showing a well-distributed size range.

- Avoid fine sands: Too much sand finer than #200 mesh increases laitance risk. Specify a maximum of 35% passing #200 in your mix design.

Placement and finishing timing guidelines

Timing is crucial for preventing laitance. Here’s how to time your operations:

Placement: Pour concrete when temperatures are between 50-90°F (10-32°C). Avoid pouring in extreme heat or cold.

Finishing: Start finishing as soon as the initial set begins, but not before. Overworking can increase laitance.

Bleeding: Allow concrete to bleed naturally. Finish when bleeding stops and a slight sheen appears on the surface. Avoid overworking during this stage.

Curing and protection strategies

Proper curing prevents early drying, reducing laitance risk:

Evaporation control: Cover concrete with plastic sheeting or wet burlap to prevent moisture loss. Keep covered for the first 72 hours.

Curing compounds: Apply a commercial curing compound after initial set. Follow manufacturer’s instructions for application and drying times.

Wet methods: For large slabs, use a sprinkler or mister to keep the surface wet during the first 7 days. Protect from wind and sun.

Aftercare, Inspection, and Preparing for Coatings or Overlays

After removing laitance, inspect the surface for soundness, uniform texture, and any residual dust or contaminants; perform final cleaning and allow the surface conditions required by your coating or overlay product. Verify moisture content and adhesion requirements as specified by the coating manufacturer before proceeding.

For best results, document your cleaning and testing steps, and if you need help interpreting test results or product limits, consult the coating or overlay manufacturer’s technical data sheet or a qualified local professional.

Visual and adhesion checks before coating

Before applying any coatings or overlays, it’s crucial to ensure your concrete surface is ready. Here’s a quick checklist to verify that.

- Cleanliness: Check for any remaining dirt, dust, or debris. A clean surface ensures better adhesion.

- Dryness: Confirm the substrate is completely dry. Moisture can compromise coatings and cause delamination.

- Profile: Ensure the surface has a suitable profile (0.5-2 mm) for coating adhesion. A smooth, flat surface may not provide enough ‘tooth’ for new materials to bond with.

- Adhesion spot tests: Perform small-scale adhesion tests using pressure-sensitive tape or paint. If the material peels off easily, your surface isn’t ready yet.

- Cracks and holes: Inspect for any cracks or holes that need filling before coating.

- Previous coatings: Check if there are any old coatings present. These should be removed to prevent delamination.

- Contaminants: Look out for any contaminants like oil, grease, or rust. These can prevent proper adhesion of new materials.

- Curing time: Ensure the concrete has cured properly (at least 28 days) before applying coatings.

Quick rule: If in doubt, perform a water drop test. A beading effect indicates a hydrophobic surface ready for coating, while absorption suggests further curing or preparation is needed.

Ongoing maintenance and monitoring

Regular maintenance and monitoring can help prevent laitance recurrence and keep your coatings in top shape. Here’s what to do:

- Visual inspection: Regularly check for any signs of delamination, cracking, or discoloration.

- Moisture testing: Conduct periodic moisture tests to ensure no hidden dampness is present.

- Cleanliness: Keep the surface clean. Dirt and debris can trap moisture and promote laitance growth.

- Sealant condition: Inspect your sealants for any signs of wear, tear, or damage that may allow water ingress.

- Temperature changes: Monitor temperature fluctuations, as extreme heat or cold can cause coatings to expand and contract, leading to cracking.

- Traffic load: Ensure the surface isn’t subjected to excessive traffic loads that could compromise its integrity.

- Snow and ice removal: Remove snow and ice promptly in winter to prevent water from seeping into cracks or pores.

- Regular cleaning: Clean your concrete regularly using a suitable cleaner to remove any dirt, algae, or mold that may grow over time.

Quick rule: Regular maintenance is key. Catch issues early to prevent small problems from becoming big, expensive ones.

When to call a professional and project considerations

While DIY can save you money, there are times when it’s best to call in the pros. Here are some warning signs:

- Large areas: If your laitance problem covers a large area (more than 100 sq ft), consider hiring professionals with specialized equipment.

- Structural concerns: If you suspect underlying structural issues, consult an engineer before proceeding.

- Persistent contamination: If you’ve tried multiple removal methods without success, it might be time to call in the experts.

- Specialized coatings: If you’re planning to apply specialized or high-performance coatings, consider hiring a professional to ensure proper application and adhesion.

- Time constraints: If your project has tight deadlines, professionals can help ensure it’s completed on time.

- Safety concerns: If the job involves working at heights, dealing with hazardous materials, or requires specialized safety equipment, consider hiring a professional to ensure safety.

- Project scope: If your project involves multiple trades (e.g., plumbing, electrical work), it might be best to hire a general contractor to oversee everything.

- Warranty considerations: Some coatings and overlays come with warranties that require professional installation to remain valid.

Quick rule: When in doubt, consult a professional. It’s better to spend a bit more upfront than risk costly mistakes or safety hazards down the line.

Conclusion

Take charge now by turning this into a solid, safe plan: addressing laitance protects the bond, improves durability, and keeps the finished surface looking right.

First, do a quick read of the site, confirm what you’ve got with a spot test, choose a removal method that fits the concrete surface, and then proceed in small steps, checking moisture, profile, and cleanliness as you go, before you seal or coat. If you’re unsure, test a tiny area first, document results, and don’t push past what the surface will tolerate. Always wear eye, skin, and respiratory protection, and keep the work area clean and well ventilated.

Common mistakes to avoid are trying to scrub off laitance with the wrong tool, over-abrading and weakening the surface, or skipping proper curing and moisture checks after any treatment. A simple safety rule is to verify adhesion with a small test patch before wide-area work and to stop if you see cracking, gouging, or dusting that keeps returning. If the surface is still suspect after treatment, or if you’re planning coatings or overlays, consult a professional rather than guessing.

If you’re unsure about the coating compatibility, or the project requires a large area, it makes sense to call in a pro. With careful planning, proper testing, and disciplined steps, you’ll finish with a durable, even surface that looks right and performs well for years to come. Stay focused, stay safe, and you’ll get there.

FAQ

How can I be sure laitance won’t ruin a new coating during prep?

Clean the surface thoroughly and perform a simple adhesion test. If the test area fails to grab or shows dusting, treat the surface before coating.

What finishing mistakes create laitance and how to fix next time?

Overworking the surface with trowels or floats can push fines to the top. Use moderate troweling, keep the surface damp but not visibly wet, and plan for proper float passes.

What are safe, non-destructive ways to test for laitance on a finished slab before coating?

Use a clean, dry cloth or a simple tape test to see if powder rubs off easily. A light, uniform test peel can reveal weak surface bonding without cutting into the slab.

When should I call a pro instead of DIY for laitance issues?

If the slab is heavily laitanced, cracked, or you’re unsure about bond for coatings, get a professional opinion. They can recommend proper surface preparation or alternative fixes based on your concrete and coating system.