Introduction

Black TPO roofing is a flexible membrane system used to create a watertight roof surface. This DIY intro gives a plain-spoken view of a fix and the stop rules you should follow on the job. You’ll focus on tools, materials, and reliable resources while avoiding surprise issues in the field.

Before you start, check the membrane type and follow the manufacturer’s instructions for application and safety. Gather basic installation tools and materials, and know when to stop if conditions or seams don’t look right. Sewing seams, applying primer, and welding work should be checked against local rules and product labels to confirm proper technique.

Key takeaways

- Inspect membrane for wear, pooling, and edge delamination before any repair.

- Use manufacturer-approved primers and adhesives compatible with black TPO membranes.

- Keep a clean substrate, remove debris, and verify surface dryness prior to adhesion.

- Seam welding requires proper heat control and overlap according to installation guidelines.

- Wear PPE: gloves, eye protection, and proper ventilation during repairs.

- Document stop rules and scheduled inspections to catch ongoing leaks early.

Table of Contents

- Introduction

- Key takeaways

- What Is Black Tpo and How It Differs from Standard Tpo

- Tools, Materials, and Safety Equipment Checklist

- Diagnosing Common Damage and Locating Issues

- Step-by-Step DIY Repair Process for Black Tpo

- Sealants, Adhesives, Primers and Material Specs

- Preventive Maintenance, Stop Rules, and Scheduling

- Common DIY Mistakes, Troubleshooting, and Quality Checkpoints

- Cost Comparison and Long-Term Considerations

- Conclusion

- FAQ

What Is Black TPO and How It Differs from Standard TPO

Black TPO is a polymer-based roofing membrane with colorants and carbon black additives that give it a dark finish. It typically uses the same thermoplastic formulation as white TPO but with a different pigment load and layer structure to achieve its hue. Common applications span residential flat roofs and commercial systems where a darker appearance or specific thermal properties are desired.

Performance differences center on heat absorption, reflectivity, and UV response. Color affects how much heat is gained and how cooling loads behave, which in turn influences insulation needs and energy use. Choose Black TPO for budget considerations, certain thermal or aesthetic requirements, and substrate compatibility, while noting potential impacts on fading and long-term reflectivity. Installation and compatibility hinge on bonding principles, primers, and adhesives, with observable cues during curing that can affect warranties. Use these practical guidelines to decide when Black TPO fits your project and when a white or standard TPO option might be a better fit.

Types and membrane properties

Black TPO membranes come in various types, each suited to different applications. Standard TPO is a single-ply membrane, while fleece-backed TPO has a reinforcing scrim for added strength. Self-adhered TPO uses a pressure-sensitive adhesive for easy installation.

Key properties to check include:

- Thickness: Thicker membranes offer better durability and insulation.

- Reinforcement: Scrim or fleece backing enhances membrane strength.

- Color-related thermal behavior: Black TPO absorbs heat, which can be beneficial in colder climates but may lead to higher cooling loads in hotter regions.

Pros and cons of black TPO for DIY projects

Black TPO can be a good choice for DIY installation, but it’s not always the best option. Here are some pros and cons to consider.

Pros

- Cost-effective: Black TPO is often cheaper than white TPO.

- Thermal mass: It absorbs heat, which can help regulate indoor temperatures in colder regions.

- Easy to install: Self-adhered black TPO rolls are simple to apply with the right primer and tools.

- Aesthetics: Black roofs can complement certain architectural styles.

Cons

- Heat gain: In hotter regions, black TPO may lead to higher cooling costs due to increased heat absorption.

- Expansion and contraction: Like all TPO, black membranes expand and contract with temperature changes, which can cause stress on the roof over time.

- Longevity: Black TPO may not last as long as white TPO in areas with intense UV exposure due to reduced reflectivity.

- Maintenance: Black roofs show dirt more easily, requiring regular cleaning to maintain their appearance.

DIY installation makes sense when the roof is small, simple, and within your skillset. Always follow manufacturer guidelines for warranty coverage.

Tools, Materials, and Safety Equipment Checklist

Start with a core tool set and safe substitutes if specialty items aren’t available. Essential hand tools include a cutting knife, scissors, a roller, a squeegee, a utility knife, and a small trowel. If a heat source is needed, use a basic heat gun and substitute household tools like a thicker roller for patches when appropriate.

Gather materials and PPE next: TPO repair patches or premade membranes, compatible primers or cleaners, seam tape or liquid adhesive, compatible sealants, edge fasteners, and a simple roller. For safety, wear gloves, eye protection, a breathable respirator when solvents are used, non-slip footwear, and fall protection near edges. Prepare a surface prep plan and a job-ready sequence to keep the work contained and organized.

Essential tools and materials

Before you start your TPO repair, make sure you have all the necessary tools and materials. Here’s a checklist to ensure you’re well-prepared.

- Heat welder or low-temp heat gun: Essential for fusing TPO seams. Verify it’s in good working condition.

- TPO patch material: Ensure it matches your roof’s membrane type and thickness.

- Seam tape/cover tape options: Have both wide and narrow tapes ready for different seam widths.

- Primers/cleaners: Compatible with TPO, they ensure proper adhesion. Check expiration dates.

- Rollers: A simple metal or plastic roller is needed for applying adhesive and pressing patches.

- Utility knife: Sharp blades are crucial for cutting patches accurately.

- Edge fasteners: Have enough to secure patch edges, preventing lift-off.

- Sealants: Compatible with TPO, they’ll seal around vents and other penetrations. Check for proper consistency.

Quick rule: Always check your tools and materials before starting to avoid mid-project delays.

Safety protocols and working-at-height guidelines

Your safety is paramount when working on a roof. Follow these guidelines to ensure a secure work environment.

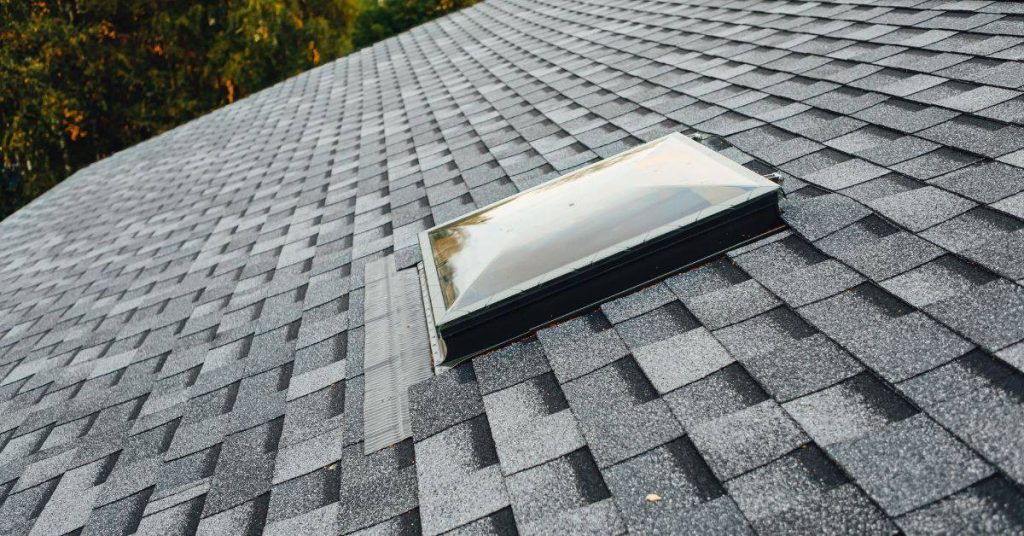

- Fall protection: Use harnesses, anchors, and lanyards when working near edges or skylights.

- Weather limits: Avoid working in wet, icy, or windy conditions. Check forecast before starting.

- Ladder setup: Ensure the ladder extends at least 3 feet above the roof’s edge. Secure it with a stabilizer if needed.

- Buddy system: Never work alone on a roof. Have someone nearby for assistance or emergency situations.

- Respiratory protection: Wear a breathable respirator when applying solvents, primers, or adhesives to prevent inhalation.

- Skin protection: Use gloves and long sleeves to protect against chemicals and UV exposure. Wear non-slip footwear for traction.

- High-traffic areas: If working near busy areas, use signs or barriers to warn passersby of the hazard.

- Eye/face protection: Wear safety glasses or goggles to protect against debris and chemical splashes.

Quick rule: Always prioritize safety. If you’re unsure about any aspect, consult a professional.

Diagnosing Common Damage and Locating Issues

Begin with a thorough visual and tactile inspection focused on seams, flashings, penetrations, and drain terminations. Note any signs of moisture intrusion at edges, ridges, and ponding areas as high-priority targets. Keep an on-roof marking system and a dated photo log to track trouble spots.

Use practical diagnostic methods to confirm issues, such as gentle moisture probing, listening for delamination, and using infrared or moisture meters if available. Document findings with a standardized diagram and prioritize repairs to guide what materials and techniques to apply. Maintain safety with fall protection and weather awareness while you examine the membrane.

Visual checkpoints and moisture testing

Use this checklist during dry weather to spot visible damage and signs of moisture intrusion.

- Seams: Check for separation, bubbles, or cracks. Any gaps can let water in.

- Flashings: Ensure they’re secure at edges, ridges, and penetrations. Lifted flashings cause leaks.

- Penetrations: Inspect vents, drains, curbs for proper sealing. Improper seals lead to water entry.

- Ponding areas: Look for trapped water. Prolonged exposure damages membrane.

- Membrane punctures: Check for holes or tears caused by debris, hail, or foot traffic.

- Moisture indicators: Use powder or spray indicators to find hidden leaks. Apply, let dry, then look for color changes.

- Infrared testing (optional): If available, use an infrared camera to detect temperature differentials indicating moisture.

- Humidity meters (optional): Measure relative humidity inside the building. High readings may indicate roof leaks.

Quick rule: Don’t ignore visible damage or signs of moisture. Address them promptly to prevent further damage.

Prioritizing repairs by severity

Not all issues require immediate attention. Here’s how to decide:

Immediate repair: Address any active leaks, open seams, or punctures right away. These cause interior damage and worsen over time.

Temporary fix: For minor seam separation, small cracks, or lifted flashings, apply temporary repairs (tape, sealant) until a permanent fix can be made. Monitor these areas closely.

Professional assessment: If you find extensive damage like widespread delamination, membrane wrinkling, or drain/clamp failure, consult a professional roofer. These issues may require specialized equipment or expertise to repair safely and effectively.

Step-by-Step DIY Repair Process for Black TPO

Define what you can DIY and what needs a pro. Focus on small punctures, seam separations, and flashing repairs, and set clear safety prerequisites like ladder use and suitable weather. Know when to pause if conditions worsen or damage appears beyond DIY scope.

List the essential items and reputable resources for product data sheets and applicable code considerations. Follow a repeatable sequence for each repair type: prep and clean, patch or adhesive application, cure and roll, then sealant checks. End with a simple post-repair inspection and documentation for future reference.

Step-by-Step Repair Process

Follow this clear, numbered sequence to safely and effectively repair your Black TPO roof. It covers preparation, main work, and final checks.

- Inspect the area: Check for any hazards like loose debris or electrical wires before starting.

- Prepare the surface: Clean the area around the damage using a brush and mild detergent to ensure proper adhesion.

- Lay out your patch/tape: Cut it to size, if necessary. For heat-welding, preheat the TPO.

- Apply the patch/tape: Use contact adhesive or heat-weld according to product instructions. Press firmly and evenly.

- Roll and check: Use a roller to ensure even pressure and adhesion. Inspect your work for any missed spots.

Patching punctures and tears

Here’s how to fix small holes or tears in your Black TPO roof. Preparation is key for a watertight result.

First, clean the area around the puncture using a brush and mild detergent. Prime it if recommended by the patch kit instructions. Cut the patch to size, ensuring it’s slightly larger than the tear. Use contact adhesive or heat-weld according to product instructions, pressing firmly and evenly. Let it cure as directed.

Note: If the tear is large or complex, consider calling a pro to avoid further damage.

Repairing seams and flashing

Seam separation and damaged flashings can lead to leaks. Here’s how to fix them:

Start by cleaning the seam or flashing using a brush and mild detergent. Apply primer/cleaner if recommended. For seams, use cover tape or heat welding according to product instructions, pressing firmly and evenly. Reinforce flashings around penetrations with additional tape or adhesive as needed.

For extensive seam separation or damaged flashings, consider calling a pro to assess the underlying cause and ensure proper repairs.

Sealants, Adhesives, Primers and Material Specs

Outline which sealants, adhesives, and primers work with black TPO and common substrates, noting any brand-to-brand cautions. Cross-compatibility with seam tapes, patches, and liquid flashing should be verified by checking product labels and data sheets. Keep a simple compatibility map handy for quick decisions on site.

Contrast solvent-based versus low-VOC options, single-part liquid flashing, and seam tapes, with typical use cases for patches, penetrations, and edge seams. Verify key specs like cure time, open time, temperature range, moisture tolerance, and substrate prep requirements by reading manufacturers’ data sheets. Document how temperature and humidity influence cure and performance.

How to choose compatible sealants and tapes

When choosing sealants, adhesives, and seam tapes for your black TPO roof repair, compatibility is key. Start by checking the manufacturer’s label or data sheet. They’ll tell you which substrates these products work best with – that includes common black TPO membranes and concrete.

Application temperature and humidity levels matter too. Most products have a safe range for application. Stay within those limits to ensure proper adhesion and curing.

For seam tapes, check if they’re compatible with your chosen sealant or adhesive. Some brands offer specific tape options designed to work best with their adhesives. Cross-compatibility can prevent failures down the line.

Storage, handling, and safe use of chemicals

Proper storage is crucial for maintaining product quality. Keep your sealants, adhesives, and primers in a cool, dry place away from direct sunlight and heat sources. Follow the manufacturer’s guidelines on shelf life and batch numbers.

When using these products, ventilation is important. Open windows or use fans to ensure proper airflow. Always wear gloves and follow safety instructions on the product label.

Before you start work, check the Safety Data Sheet (SDS) for each product. It’ll tell you what personal protective equipment (PPE) to wear, how to handle spills, and disposal procedures. Keep these SDS sheets handy on-site.

Preventive Maintenance, Stop Rules, and Scheduling

Set a DIY-friendly preventive maintenance cadence with monthly quick checks, seasonal deep-inspections in spring and fall, and post-storm reviews to catch damage early. Establish stop rules that trigger a halt and professional assessment if issues appear beyond your comfort level. Use these thresholds to avoid unnecessary risk.

Provide an actionable inspection checklist covering seams, flashing, sealant wear, debris accumulation, UV degradation, and signs of blistering or delamination. Maintain a simple maintenance log with dates, issues observed, tasks completed, and follow-up reminders. Know when to call a professional if persistent leaks or structural concerns arise.

Routine maintenance checklist

Use this checklist monthly to keep your TPO roof in tip-top shape. Catch minor issues early and prolong membrane life.

- Debris removal: Clear off leaves, twigs, and dirt that can hold moisture and cause damage.

- Drain clearing: Ensure drains are free of debris to prevent water buildup.

- Seam checks: Inspect all seams for signs of separation or cracking. Early detection prevents leaks from spreading.

- Spot repairs: Address minor punctures, tears, or blisters immediately to stop them from growing.

- UV degradation check: Look for discoloration or brittleness caused by sun exposure. UV damage can lead to leaks.

- Fastener check: Ensure all fasteners are secure and not exposed. Exposed fasteners can let water in.

- Edge curl inspection: Check edges for excessive curling, which can cause leaks if left unchecked.

- Blistering/delamination check: Look for signs of blisters or delamination, indicating underlying moisture problems.

Quick rule: If you find any issues, address them promptly to prevent minor problems from becoming major headaches.

Stop rules and red flags

Knowing when to stop DIY work and call a professional is crucial. Here are clear signs that it’s time to escalate:

Ponding water: If water ponds on your roof for more than 48 hours after rain, it’s a sign of drainage issues or underlying problems that need professional attention.

Extensive seam failure: Multiple failing seams indicate a larger problem that requires a pro to assess and fix.

Insulation saturation: If you suspect your insulation is wet, it’s time to call in the experts. This could indicate structural issues or extensive leaks.

Structural concerns: Any signs of sagging, buckling, or other structural issues require immediate professional assessment and repair.

Repeated leaks: If you’re constantly patching the same leak, it’s a sign that there’s an underlying problem that needs professional diagnosis and repair.

Common DIY Mistakes, Troubleshooting, and Quality Checkpoints

Highlight frequent errors like inadequate surface preparation, using the wrong adhesive or sealant, ignoring substrate moisture, and rough seam technique. These mistakes often lead to poor adhesion and leaks, so verify surface readiness before patching. Keep expectations realistic about DIY outcomes.

Follow a troubleshooting flow: locate the leak source, determine if it’s a surface issue or seam problem, address moisture first, then reseal and re-test. Use quality checkpoints during repair, such as adhesion tests on test patches and confirming proper flashing and edge terminations. Capture before/after photos and document results for warranties.

How to test and verify your repair

After completing a DIY TPO roofing repair, it’s crucial to ensure the fix holds. Use this checklist to confirm your work.

- Water spot check: Inspect repaired areas from above for any signs of water spots or leaks.

- Low-angle flashlight test: Use a flashlight at a low angle to reveal any wrinkles, gaps, or missed spots on the surface membrane.

- Controlled water spray test: Spray the repaired area with water for 5-10 minutes. Watch for leaks or water penetration.

- Monitor for creeping leaks: Keep an eye on the repair over the next few days to ensure no new leaks appear due to shifting or movement.

- Check seam continuity: Inspect all seams and ensure they are properly sealed with no gaps or tears.

- Verify edge terminations: Ensure flashings and edge terminations are secure and properly installed to prevent water intrusion.

- Adhesion test: Perform a simple adhesion test on a small, hidden patch to ensure the membrane adheres well to the substrate.

- Ponding check: Inspect for any areas where water may pond or collect. This can indicate an uneven surface or improper drainage.

Quick rule: Regularly inspect your repair, especially after heavy rain or wind events, to catch any potential issues early.

When a DIY repair fails — next steps

If a DIY TPO roofing repair fails, follow this checklist to assess the situation and take appropriate action.

- Locate the leak: Identify where the water is entering. It could be a new issue or a recurring problem at the same spot.

- Assess the damage: Determine the extent of the damage and whether it’s a surface membrane issue, joint seam problem, or something else.

- Document the failure: Take photos and notes detailing the failed repair. This will be crucial for any warranty claims or insurance purposes.

- Temporary fix: If possible, perform a temporary emergency fix to prevent further water damage until professional help arrives.

- Contact a professional: Reach out to a licensed roofing contractor to assess the situation and provide an estimate for repairs.

- Check weather conditions: Ensure it’s safe for you or the contractor to work on the roof. Avoid working in high winds, heavy rain, or extreme temperatures.

- Review warranties: Check your product warranties and any applicable insurance policies to see what’s covered and who to contact.

- Communicate with contractors: Clearly explain the issue and provide them with all relevant information, including photos and notes from your assessment.

Quick rule: Don’t attempt further repairs if you’re unsure about the cause of the failure. It’s better to consult a professional to avoid causing more damage.

Cost Comparison and Long-Term Considerations

Break down costs into materials, tools/equipment, PPE, disposal, and any permits or inspections. Separate DIY ranges from professional quotes and use these as a budgeting guide. Remember these figures are project-based estimates and should be verified locally.

Compare scenarios like a small DIY patch versus full membrane repair or replacement, and evaluate when professional intervention is financially prudent. Consider long-term durability, warranty implications, maintenance frequency, and potential hidden costs such as site prep or debris disposal. Use a decision framework to weigh cost savings against risk and reliability.

Budgeting and smart trade-offs for DIYers

When tackling a DIY TPO roof repair, it’s crucial to budget wisely. Spend more on quality adhesives and sealants. These are the backbone of your repair. Don’t skimp here.

Invest in safety gear too. A good harness, helmet, and gloves can prevent costly injuries. It’s a small price to pay for peace of mind.

For tools, consider renting high-use items like heat-welders or adhesive applicators. The cost is often lower than buying, especially if you only need them occasionally. Plus, you won’t have to maintain and store them.

But, do buy your own basic safety gear. It’s a one-time investment that’ll serve you well throughout your DIY adventures.

Sustainability and lifespan implications

Your repair choice directly impacts your roof’s longevity. A thorough, professional-grade job can extend your TPO’s life by years. It’s like giving it a second chance.

Energy performance is another factor. Black TPO absorbs heat, making your home hotter in summer. Consider applying reflective coatings or overlays to boost energy efficiency and reduce cooling costs.

Regular inspections also play a big role. Schedule them annually to catch issues early. This proactive approach can double your roof’s lifespan.

Remember, while DIY repairs save money, they might not match the longevity of professional work. Weigh this trade-off before you start.

Conclusion

Finish with a durable, safe black TPO repair that keeps water out, looks clean, and stands up to weather. The right steps, done carefully, protect the roof, save you money, and avoid costly callbacks.

Check the surface and repair plan in one go, then proceed in a calm, logical order: verify the damage, confirm you have the correct sealants and primers, test materials on a small area, clean and dry the work spot, follow the stop rules, set aside a dedicated dry window, and apply repairs in thin, even coats with full curing between steps. Confirm PPE and ventilation are in place, keep a tidy work area, and document each stage as you go so you’re not guessing later.

Common mistakes to watch for include rushing repairs, using the wrong adhesive or primer, or skipping surface prep and test patches. Always slow down for a proper test patch, follow the manufacturer’s instructions, and never apply sealants over damp or dirty TPO. If something feels uncertain or a repair requires more than basic patches, pause and reassess safety and feasibility before continuing—never push on when the risk of damage or personal injury rises.

If you’re not confident about large patches, flashing transitions, or complex roof sections, call a professional sooner rather than later. A pro can confirm material specs, ensure proper adhesion, and execute critical areas safely. Stay practical, stay safe, and you’ll finish with a job that lasts and protects the roof for years to come. Safety first, steady progress, and clear expectations are your best tools for success.

FAQ

What tools and materials do I need for Black TPO roof DIY repair?

Have the manufacturer’s instructions handy and gather basic hand tools, a heat gun or seaming iron if you’ll weld seams, rollers, brushes, and cleaners specified for TPO. Use only compatible primers, sealants, and patches as rated on the product label. Check local rules or product data if you’re unsure about a particular item.

How do I apply Black TPO sealant and ensure proper adhesion?

Clean the surface as directed and apply a primer if required. Spread the sealant evenly, press the patch or seam area into place, and roll or press to remove air. Do not overuse and follow curing times shown on the product label.

What are seam welding details and how should I do them safely?

Follow the membrane manufacturer’s seam welding instructions exactly. Keep the heat at the recommended setting, steady movement, and avoid scorching. Wear proper PPE and ventilate the area; never weld near ignition sources or damaged areas that aren’t prepared per instructions.

What should I check if the repair still leaks or looks odd?

Inspect seams, patches, and flashings for gaps or lifted edges. Re-clean and re-prime any suspect areas and re-weld or reseal as instructed by the product label. If you’re unsure, consult the manufacturer’s troubleshooting guide or a local pro before proceeding.