Introduction

Stitching is a repair method that reinforces cracked concrete block corners without tearing down the wall. It typically uses patch material and stitching along the crack to help hold blocks in place. Check the crack width, water intrusion, and follow the manufacturer instructions and local rules before starting.

Rebuild is when you take out the damaged corner and rebuild it to restore strength and alignment. This option is more involved and may require new mortar, block, and proper alignment, plus flashing or waterproofing considerations. Always verify with product labels and local codes for tolerance, cure times, and best practices before proceeding.

Key takeaways

- Assess crack pattern and corner condition before choosing stitching or rebuilding approach.

- Select compatible stitching materials; ensure mix, thickness, and cure follow manufacturer guidance.

- Inspect for moisture, frost damage, or movement; wear eye protection during repair.

- Partial rebuild may save effort but must maintain structural compatibility and flashings.

- Document permit, safety precautions, and material QC checks during planning.

- Evaluate long-term maintenance needs to avoid repeated corner cracking.

Table of Contents

- Introduction

- Key takeaways

- Causes of Corner Cracking and Common Failure Patterns

- Inspection and Initial Assessment Checklist

- Stitching Technique: Materials, Method, and Limitations

- Rebuilding Corners: Partial Vs Full Rebuild and Best Practices

- Decision Framework — Where to Draw the Line

- Material Specs, Standards, and Quality-Control Points

- Project Planning, Safety, Permits, Costs, and Maintenance

- Conclusion

- FAQ

Causes of Corner Cracking and Common Failure Patterns

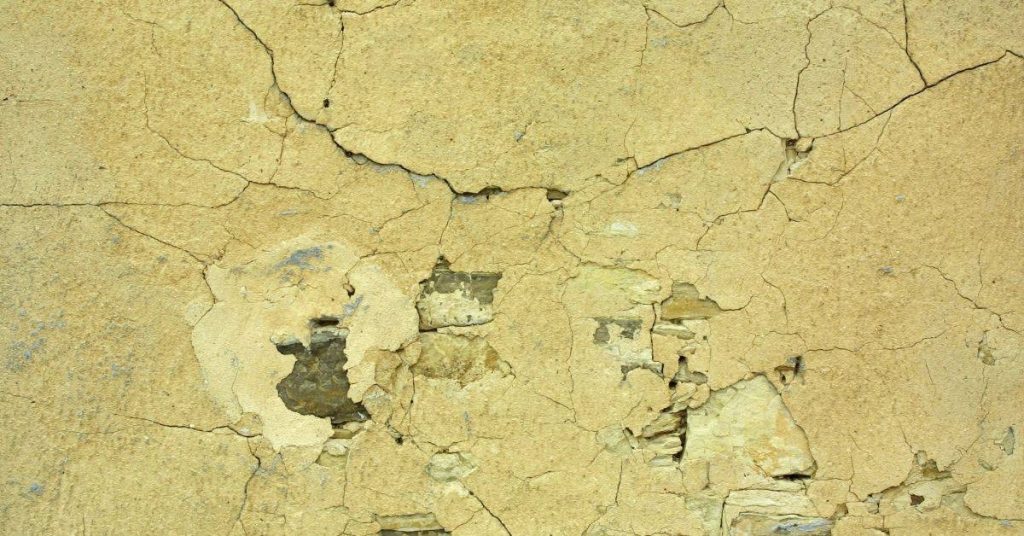

Cracks at block corners often result from structural load, settlement, or poor initial construction. Freeze-thaw cycles and water infiltration can worsen existing gaps. Corrosion of internal reinforcement is another root cause that can drive cracking from the inside out.

Look for patterns such as stepped cracks along the corner, widening at joints, or hairline fissures that run vertically or diagonally. Note whether cracks align with mortar joints or block face corners. For any crack that seems to be moving or paired with visible deflection, verify with a structural professional or refer to the product label and local code guidance.

Structural vs non-structural cracks

A crack in your concrete block corner isn’t always a sign of serious trouble. Some are just cosmetic, but others can indicate major issues. Let’s learn how to tell them apart.

First off, structural cracks usually run diagonally or horizontally across the wall. They often start at corners and propagate towards the center. If you see these, it might be a sign of settlement or excessive loading.

Now, non-structural cracks, on the other hand, typically appear vertically or randomly. They’re usually hairline thin and don’t widen over time. These are mostly due to minor shrinkage during curing or slight movement in the foundation.

Environmental and material contributors

Choosing the right materials for your concrete blocks is crucial. The wrong ones can lead to all sorts of problems, including cracking at corners.

- Moisture and freeze-thaw cycles: Excess water in pores can freeze and expand, causing cracks. Use proper drainage and sealants to prevent this.

- Efflorescence: This white powdery deposit can weaken the bond between blocks and mortar. Clean it off with a acid solution before repairs.

- Poor mortar mix: A weak mix can’t hold blocks together properly, leading to cracks. Use a mix with at least 1:3 cement-to-sand ratio for strength.

- Corroded embeds: Rust from reinforcement or metal anchors can cause cracks as it expands. Inspect and replace any corroded embeds before repairs.

Inspection and Initial Assessment Checklist

Walk the exterior and interior corners to gauge crack width and movement. Photograph both sides of the corner from multiple angles for tracking changes over time. Measure crack length and any offset between blocks where practical.

Check for moisture intrusion, efflorescence, or damp spots that signal water issues. Red flags include significant displacement, bulging, or visible instability; these require immediate attention from an engineer or shoring considerations per your local rules. Always consult manufacturer instructions or local standards for reference on assessment methods.

Visual and tactile checkpoints

Before you start any repair, use this checklist to assess the damage visually and tactically.

- Separation: Check for gaps between blocks. If present, measure their width.

- Bulging: Look for outward curvature of the wall. Press gently to confirm.

- Stepped cracks: Inspect for diagonal or horizontal cracks at corners.

- Loose masonry: Probe around joints with a screwdriver. If it goes in easily, there’s a problem.

- Hollowness: Tap the wall. A dull sound indicates empty spaces inside.

- Crack width: Measure any cracks’ widths using a crack gauge or feeler gauge.

- Crack pattern: Note if cracks are diagonal, horizontal, or vertical.

- Moisture: Check for dampness around cracks or joints.

Quick rule: If you’re unsure about any findings, it’s better to seek professional advice.

When to call a structural engineer

Certain signs indicate the need for professional assessment. Use this checklist to identify them.

- Movement: Check if walls or corners are moving or shifting.

- Load-bearing corners: If cracks are at load-bearing corners, call a pro.

- Cracks progressing: If temporary fixes don’t stop cracks from growing, get help.

- Vertical cracks: These can indicate serious structural issues.

- Diagonal cracks above windows/doors: These may signal lintel failure.

- Cracking at new construction joints: This could mean the concrete is shrinking too much.

- Excessive bulging or leaning: Severe outward curvature or tilting needs professional attention.

- Visible rust on reinforcement: This can indicate corrosion and loss of strength.

Quick rule: If you notice any of these signs, don’t wait. Call a structural engineer immediately.

Stitching Technique: Materials, Method, and Limitations

Stitching uses reinforcement across the crack with drill-set anchors or bonded dowels to hold cracked sections together. You’ll typically need compatible epoxy or grout and appropriate anchors suited to block and mortar systems. This approach aims to arrest movement and transfer loads across the cracked area.

Consider stitching when the crack is notable but the surrounding structure remains sound. Check product instructions and local code requirements to confirm suitability and any limitations, such as crack width or aggregate size. If in doubt, verify with the material supplier or a qualified professional.

Tools and materials checklist for stitching

Before you start, make sure you have everything needed for a successful stitch repair. Here’s a quick checklist to ensure you’re well-equipped.

- Drill: A heavy-duty drill with masonry bits is essential for creating holes in the concrete blocks.

- Corrosion-resistant dowels/rods: Stainless steel or galvanized rods prevent corrosion and ensure longevity. Check they’re the right size for your drill bit.

- Epoxy/structural grout: This bonds the dowels to the blocks, providing strength. Ensure it’s compatible with your existing materials.

- Resin cartridges: For easy application of epoxy or grout, use cartridges designed for caulk guns.

- Caulk gun: To apply epoxy or grout from the cartridges.

- Tape measure: Measure and mark drill locations accurately to ensure even spacing.

- Masonry bit set: A set of masonry bits ensures you have the right size for your dowels.

- Safety gear: Include safety glasses, gloves, and ear protection. Check they’re in good condition before starting.

Quick rule: Always double-check your materials to ensure they’re compatible with each other and suitable for the job at hand.

Step-by-step stitching procedure

Follow this step-by-step guide to achieve a strong, lasting stitch repair in your concrete block corners.

- Prepare the area: Clean and dry the cracked area. Remove any loose material or debris.

- Mark drill locations: Using a tape measure, mark evenly spaced points along the crack for drilling. Aim for 12-16 inches apart.

- Drill holes: Drill through both blocks at each marked point using your masonry bit and drill. Ensure you go deep enough to embed the dowels fully.

- Insert dowels: Cut dowels to length, then insert them into the drilled holes. They should fit snugly with no play.

- Mix and apply epoxy/grout: Mix your chosen epoxy or structural grout according to the manufacturer’s instructions. Apply it liberally around each dowel using a caulk gun.

- Bond the blocks: Press the blocks together firmly, ensuring they’re aligned properly. Use clamps if necessary to maintain pressure while the epoxy/grout cures.

- Allow curing: Follow the manufacturer’s instructions for cure time. This is typically 24-72 hours.

- Inspect and test: Once cured, check that the blocks are securely bonded together. Gently try to move them; there should be no play or movement.

Limitations and failure modes of stitching

Stitching is a powerful repair technique, but it’s not suitable for every situation. Here are some limitations to consider:

Ongoing movement: If the original cause of the cracking (e.g., settling, soil erosion) isn’t addressed, stitching may fail over time as the blocks continue to move.

Extensive loss of block/mortar: If large chunks of block or mortar are missing, stitching alone won’t be enough. You’ll need to rebuild those areas first.

Corroded embeds: If existing reinforcement (like rebar) is corroded, it may not provide the necessary support for a successful stitch repair. In this case, consider rebuilding or replacing the affected area.

Signs of an inadequate repair include continued cracking, movement, or play in the blocks after they’ve been stitched. If you notice any of these signs, consult a structural engineer to assess the situation further.

Rebuilding Corners: Partial Vs Full Rebuild and Best Practices

A partial rebuild targets only the compromised units or a single corner; it minimizes disruption and preserves most of the existing wall. A full corner rebuild replaces the entire corner to restore strength and load path. Both approaches require proper sequencing and support to avoid new stresses.

Plan for load transfer during work and ensure temporary shoring if needed. Always follow local standards and obtain any required permits or engineer input when structural conditions are uncertain. Verify material compatibility and curing methods before installing new units.

Partial Rebuild Workflow

Start by removing damaged blocks. Use a chisel and hammer, working from the top down to prevent further damage.

Prepare adjacent masonry. Clean joints and faces using a wire brush. Ensure all surfaces are sound before proceeding.

Install new units. Match them to existing blocks in size and texture. Use Type N or Type S mortar, mixing it well. Apply mortar to the bed and ends of each block, then set them carefully into place.

Reinforce as needed. If structural integrity is compromised, install rebar or other reinforcement before pointing joints.

Full Corner Rebuild Considerations

A full rebuild may be necessary if there’s extensive damage, misalignment, or persistent moisture. It involves removing all blocks in the affected area and starting fresh.

Tying into existing wall. Remove enough blocks to expose a solid, stable surface. Apply construction adhesive along this surface before installing new blocks to ensure a strong bond.

Temporary support is crucial. Before removing any blocks, install temporary supports to bear the load and prevent collapse. Use acrow props or similar devices, ensuring they’re secure and level.

Consider hiring help for this task. A full rebuild can be heavy work, and safety should always be your top priority.

Matching Appearance and Performance

To blend your repair with the existing structure, match block size, texture, and color. Obtain new blocks from the same batch or source as originals to ensure consistency.

Mortar color. Match mortar color by adding integral pigments to your mix. Test small batches first to get it right.

Match compressive strength. Ensure new blocks have the same or similar compressive strength as existing ones for structural compatibility. Check manufacturer specs if needed.

Inspect your work. Once complete, visually inspect and test your repair to ensure it blends seamlessly with the rest of the structure.

Decision Framework — Where to Draw the Line

Assess damage severity, structural role of the wall, and evidence of movement or moisture issues. Use a practical checklist to decide between stitching and rebuilding based on stability and expected performance. Consider time, cost, and disruption to determine the most reliable option.

Involve a pro if movement is ongoing, cracks are widening, or joints show significant displacement. Reference local standards and manufacturer guidance to balance safety and practicality. For any decision, verify relevant codes and recommendations before proceeding.

Damage-severity checklist

Use this checklist before deciding whether to repair or replace a damaged concrete corner. It’ll help you understand the severity of damage and plan your work accordingly.

- Crack width: Measure the widest crack with a ruler. A hairline crack (less than 1/8″) is minor, while anything wider is moderate to severe.

- Crack depth: Check how deep cracks go using a screwdriver or a deep probe. Shallow cracks (less than 1/4″) are minor, but deeper ones indicate more severe damage.

- Crumbing: Gently tap the corner with a hammer. Minor damage has slight crumbling, while moderate to severe has significant crumbling or pieces falling off.

- Delamination: Check if the concrete layers are separating (delaminating). This is severe and requires immediate attention.

- Reinforcement exposure: Look for exposed rebar. Even a small amount indicates moderate to severe damage, as it’s vulnerable to corrosion.

- Water intrusion: Check if water is entering the crack or corner. This can cause further damage and should be addressed promptly.

- Structural movement: Gently push and pull the damaged area. Any movement indicates severe structural damage that needs immediate professional attention.

- Corrosion stains: Look for rust-colored stains, which indicate rebar corrosion. This is a sign of moderate to severe damage.

Quick rule: If you find any signs of severe damage or structural movement, stop and consult a professional before proceeding with repairs.

Risk and lifecycle considerations

When deciding between stitching or rebuilding a concrete surface, consider the long-term impact on your wallet and safety. Here’s what you need to think about:

Expected Service Life: Stitching can be cheaper upfront but it’s like putting a band-aid on a broken bone. It might hold for a while, but eventually, the damage will show again. Rebuilding, on the other hand, is more expensive but gives you a fresh start with a new lifespan.

If your concrete has structural cracks or significant damage, stitching might not be enough to save it. Check the damage severity checklist from earlier and consider getting professional advice if you’re unsure.

Occupant Safety: Safety should always come first. If your concrete is cracked or crumbling, it could pose a tripping hazard or even collapse under weight. Stitching might not fix these issues completely, so consider rebuilding if safety is a concern.

Material Specs, Standards, and Quality-Control Points

Mortar compatibility with existing blocks is essential for a durable repair. Request information on grout or epoxy types and corrosion resistance of any steel components. Cross-check these choices against local building standards and product data sheets.

Ask for tests or verifications to confirm bond strength, compressive capacity, and proper curing. If unsure, verify requirements with the supplier, manufacturer instructions, or local code authority before purchasing materials.

What to verify on product labels and data sheets

When you’re repairing cracked concrete block corners, the materials you use matter. Here’s what to check on product labels and datasheets:

Mortar Compatibility: Ensure it matches your existing masonry. Look for similar ingredients and performance ratings.

Grout/Epoxy Type: Check if it’s suitable for your application. Thinset is often used with concrete blocks, but read the data sheet to be sure.

Corrosion Resistance of Steel: If using steel reinforcement, ensure it’s galvanized or stainless steel to prevent rusting.

Visual and measurable quality checkpoints

Before you start your repair, use this checklist to ensure everything is in order. It’s best to do these checks after you’ve completed each step of the process.

- Embed Depth: Check that reinforcement bars are properly embedded (usually 2-3 inches from the edge).

- No Gaps in Grout/Epoxy: Ensure there are no voids or gaps. Tap the surface to help settle any air pockets.

- Flush Finishing: Make sure the final layer is flush with the existing surface to prevent tripping hazards and water pooling.

- Proper Curing: Follow manufacturer guidelines for curing time and conditions (usually 28 days).

- No Ongoing Movement: Check for any signs of further movement or cracking after the repair is complete.

- Match Color and Texture: Ensure your repair matches the existing concrete as closely as possible.

- Check for Delamination: Tap the surface to listen for a hollow sound, which could indicate delamination (separation of layers).

- Verify Structural Soundness: If you’re unsure about any aspect, consult a structural engineer.

Quick rule: Regular checks ensure your repair is strong and durable. Don’t skip them!

Project Planning, Safety, Permits, Costs, and Maintenance

Outline the work sequence, including shoring, crack treatment, and any rebuild steps. Develop a clear safety plan covering PPE, fall protection, and debris control. Plan for weather and access constraints to avoid delays.

Identify permit needs and rough cost/time expectations based on your scope. After repair, set a maintenance schedule to monitor cracks and water intrusion. Always verify permit requirements and maintenance guidelines with local authorities or building professionals.

Safety and Temporary Support

Before you start, ensure the area is safe. If corners are load-bearing or unstable, you’ll need temporary support.

Shoring is key here. It’s like building a scaffold to hold up the weight while you work. You can use 2x4s or adjustable posts, but make sure they’re sturdy and secure.

Wear safety gear – hard hat, gloves, and eye protection. Be mindful of your surroundings; keep tools and materials organized to prevent trips and falls.

Permits, Contractor Selection, and Cost Considerations

Check with your local building department for permits. You might need one if you’re rebuilding or changing the structure.

If hiring help, vet contractors carefully. Ask for references, check licenses, and look at past work. Get quotes from a few to compare apples to apples – don’t just pick the cheapest.

Costs vary by location and job size. Expect to pay more for full rebuilds than stitching. But remember, cheaper isn’t always better. Quality materials and workmanship save you money in the long run.

Aftercare and Monitoring

Regularly check your repair to ensure it’s holding up. Look for any signs of re-opening or movement – cracks, gaps, or shifting.

Use simple tools like a level or straight edge to spot issues early. The sooner you catch problems, the easier (and cheaper) they are to fix.

Maintain your repair. Keep the area clean and free of debris. Seal any small cracks that appear with a concrete sealer to prevent water intrusion and further damage.

Conclusion

Repairing cracked concrete block corners is about safety, durability, and keeping the look tight. Decide early whether stitching will handle the crack or if a rebuild is needed, then move with clear steps and steady work.

Follow this practical check as you proceed: assess the crack pattern and any movement, inspect for hollow or loose blocks, verify the wall is structurally sound, choose stitching or rebuilding based on the plan, confirm required permits and material specs, gather safety gear and tools, test a small area first, then lay out a step-by-step plan with realistic timing and a budget, and finally review your work for quality and drainage or moisture considerations.

Common mistakes to avoid are rushing the assessment, using improper or incompatible materials, and skipping a small-test run that reveals hidden movement. Always keep a tight safety focus: wear eye protection, dust mask, gloves; support the structure if you notice movement; and never mix repair materials without checking compatibility or curing requirements.

If you find persistent movement, widespread deterioration, or uncertain load conditions, call a professional before you push ahead. With proper planning, sensible scope, and careful execution, you can restore corners that last and look right, then move on to the next project with confidence.

FAQ

How do I decide when to stitch cracks or rebuild the corner?

Stitching is often for small, non-structural cracks that run along the face or short spans. If the cracks are wide, deep, or show movement after loading, a rebuild is safer. Check the crack behavior and any movement with your own eyes and follow the manufacturer’s repair instructions or local guidance for durability.

What should I look for to avoid turning a quick patch into a bigger problem?

Look for water intrusion, block spalling, or any shift in alignment around the corner. If you see hollow blocks or missing mortar, that’s a warning sign. Stop and assess before continuing; poor conditions can ruin a repair fast.

What tools and materials are essential for a clean repair job?

Have a chisel or grinder for clean cuts, mortar mix that matches the existing mortar, filler or stitch pins if used, and a trowel or pointing tool. Read the label on mortar bags and adhesives for any curing or safety notes. Follow local rules and product instructions to ensure compatibility with concrete blocks.

What about maintenance after fixing the corner?

Keep the area dry and inspect periodically for new cracks or moisture entry. Repoint or reseal as needed per product guidance and your local climate. If you see recurring cracking, reassess with a professional or consult the manufacturer’s instructions for follow-up steps.