Table of Contents

- Introduction

- Understanding Concrete Hardness

- Coating Requirements for Microtopping

- Time Efficiency in Surface Preparation

- Versatility of Tools and Equipment

- Proper Surface Preparation and Cleaning

- Safety Precautions in Microtopping Application

- Cost Analysis of Tools and Materials

- Knowing When to Call in the Pros for Microtopping

- Common Mistakes and How to Avoid Them

- Environmental Considerations and Sustainable Practices

- Conclusion

- FAQ

Introduction

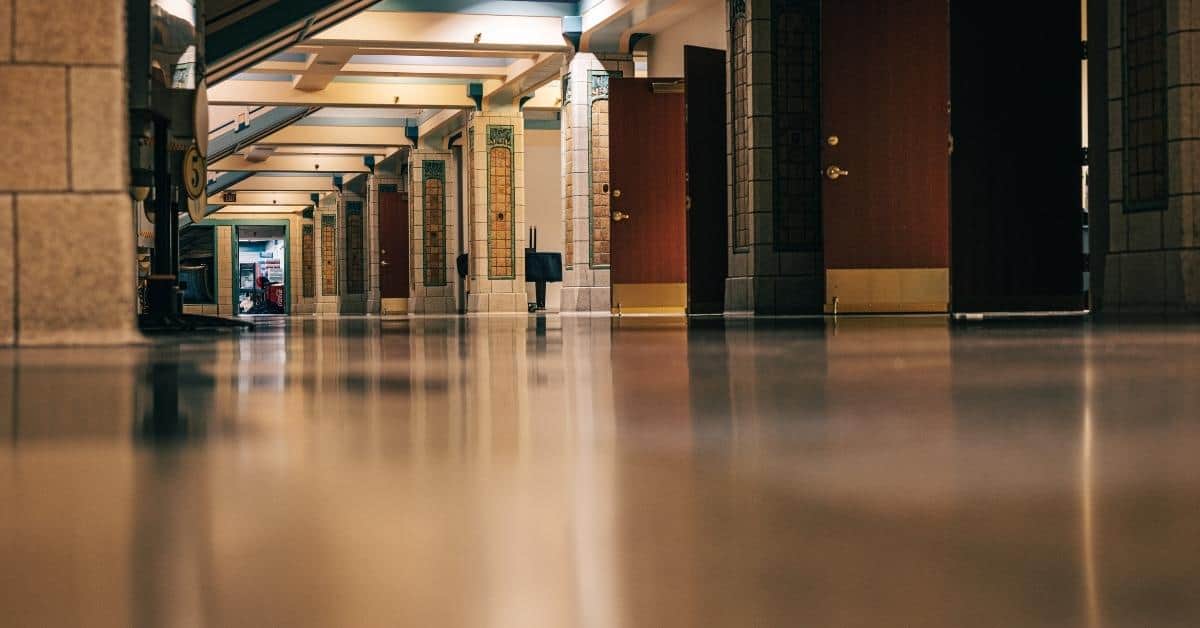

To prepare a polished surface for microtopping, you need to create a scratch profile that ensures proper adhesion. This article will guide you through the essential steps and considerations for achieving the ideal surface texture, ensuring a durable and aesthetically pleasing finish.

Understanding Concrete Hardness

Understanding the hardness of concrete is crucial before beginning any microtopping project. Knowing the concrete’s hardness ensures proper adhesion and longevity of the microtopping, preventing future issues and ensuring a successful application.

Mohs Scale and Scratch Test

The Mohs scale is a straightforward way to gauge concrete hardness. It ranks materials from 1 to 10, with 1 being the softest and 10 the hardest. To use it, you’ll need a set of mineral picks or common items like a steel file or a glass piece. Start by trying to scratch the concrete with a tool of known hardness. If the tool leaves a mark, the concrete is softer than the tool. If not, it’s harder.

For a quick check, use a scratch test. Take a sharp object like a nail or a key and try to scratch the surface. If the concrete scratches easily, it’s likely on the softer side. If it resists, it’s harder. This method isn’t precise but gives you a rough idea of the surface toughness.

Remember, a harder surface might be more durable, but it can also be more brittle. Balance is key. If you’re unsure, consult a professional to avoid costly mistakes. Don’t just rely on one test; consider the overall condition and intended use of your concrete.

Coating Requirements for Microtopping

Proper coating and bonding techniques are essential for achieving a successful microtopping application. This section explores the specific requirements needed to ensure durability and adhesion in microtopping projects.

Bonding Techniques

When applying microtopping on polished surfaces, the first step is to ensure the surface is properly prepared. Polished surfaces are smooth and can repel coatings if not treated correctly. Start by cleaning the surface thoroughly to remove any dust, grease, or debris. A clean surface is crucial for a good bond.

Next, use a mechanical grinder to roughen up the polished surface. This creates a texture that helps the microtopping adhere better. Be thorough but cautious; you want to avoid over-grinding, which can weaken the base structure. After grinding, clean the surface again to remove any resulting dust.

Apply a high-quality bonding agent to the roughened surface. This step is non-negotiable. The bonding agent acts as a bridge between the polished surface and the microtopping, ensuring a strong, long-lasting bond. Follow the manufacturer’s instructions for application and drying times.

Finally, once the bonding agent is ready, apply the microtopping evenly. Work in small sections to maintain control and ensure uniformity. Remember, rushing this process can lead to uneven surfaces and weak spots. Take your time to get it right.

Time Efficiency in Surface Preparation

Microtopping and other advanced surface preparation methods significantly reduce the time required for project completion. By streamlining processes and minimizing labor-intensive tasks, these techniques offer efficient solutions for both residential and commercial applications.

Comparing Methods

When it comes to surface preparation, you’ve got a few options. The most common methods are sanding, chemical stripping, and power washing. Sanding is often the go-to for smaller projects. It’s straightforward but can be time-consuming if you’re dealing with a large area. Make sure to check base compaction after sanding to ensure a smooth finish.

Chemical stripping is faster for removing old paint or finishes, but it’s messy and requires careful handling. Always follow safety instructions to avoid damaging the surface or harming yourself. Power washing is quick and efficient for outdoor surfaces like decks or driveways. However, be cautious with the pressure settings to prevent surface damage.

In the end, the best method depends on your specific project. For small indoor jobs, sanding might be your best bet. For larger or outdoor areas, consider power washing. If you need to strip old layers, chemical stripping can save you time but requires more care. Choose wisely to save both time and effort.

Versatility of Tools and Equipment

Surface profiling can be achieved using a diverse array of tools and equipment, each suited to different applications and materials. From precision instruments for detailed analysis to robust machinery for larger projects, the versatility of available tools ensures that every profiling need is met efficiently and effectively.

Interchangeable Tooling Options

Interchangeable tooling is a game-changer for surface preparation. It lets you switch tools quickly, saving time and effort. This flexibility means you can tackle different surfaces without needing a whole new set of equipment.

- Angle Grinder – Perfect for grinding, cutting, and polishing. Make sure to use the right disc for the job to avoid damaging surfaces.

- Sanding Pad – Great for smoothing surfaces. Always start with a coarse grit and work your way to finer grits for the best finish.

- Wire Brush – Ideal for rust removal and cleaning. Use it gently to avoid scratching softer materials.

- Paint Scraper – Essential for removing old paint and coatings. Keep it sharp for better efficiency and less effort.

- Drill Attachments – Versatile for drilling, buffing, and more. Match the attachment to the material to prevent damage.

Pro tip: Always check the compatibility of your tooling with your equipment to avoid mishaps and ensure the best performance on-site.

Proper Surface Preparation and Cleaning

Proper surface preparation and cleaning are crucial steps to ensure the successful application of microtopping. By thoroughly cleaning and preparing the surface, you can enhance adhesion and durability, leading to a smoother and longer-lasting finish.

Cleaning Techniques

Before you even think about applying anything to a polished surface, make sure it’s absolutely clean. Start by removing any dust or loose debris with a soft, dry cloth. This prevents scratches and ensures that nothing gets trapped under the finish. If the surface is particularly dusty, use a vacuum with a brush attachment to avoid scattering particles.

Next, tackle any greasy or oily spots. A mild detergent mixed with warm water usually does the trick. Use a soft sponge to gently scrub the area, then rinse thoroughly with clean water. Don’t leave any soap residue behind, as this can interfere with adhesion. Dry the surface completely with a lint-free cloth.

For stubborn stains, a little bit of isopropyl alcohol on a cloth can be effective. Rub gently and avoid soaking the surface. Remember, the goal is to remove contaminants without damaging the polish. Be cautious with abrasive cleaners or pads—they can ruin the finish and make it impossible for anything to stick properly.

Surface Inspection

Before you even think about applying microtopping, take a good look at your surface. You need to inspect for dirt and debris because these can ruin your finish. If you skip this step, you’re asking for trouble. Dirt and loose particles will prevent the microtopping from sticking properly, leading to bubbles and peeling.

Get down close and feel the surface. Is it smooth? Are there any rough patches or sticky spots? These need to be addressed. Use a broom or a vacuum to remove loose debris. If you find any sticky or oily areas, clean them thoroughly. A clean surface is your best friend when it comes to microtopping.

Don’t just assume the surface is ready because it looks okay from a distance. Check every inch. If you find cracks or holes, fill them in before you start. This isn’t just about aesthetics; it’s about ensuring the durability of your microtopping. Trust me, a little extra time spent on inspection can save you a lot of headaches down the road.

Safety Precautions in Microtopping Application

Ensuring safety during microtopping application involves wearing protective gear and following proper ventilation guidelines. These precautions are essential to prevent inhalation of dust and contact with potentially harmful chemicals, ensuring a safe and efficient application process.

Personal Protective Equipment (PPE)

When you’re applying microtopping, safety should be your top priority. Using the right personal protective equipment (PPE) keeps you safe from dust, chemicals, and potential injuries. Here’s what you need to wear to protect yourself.

- Safety Glasses: Protect your eyes from dust and splashes. You don’t want anything getting in your eyes while you’re focused on the task.

- Respirator Mask: Keeps harmful dust and fumes out of your lungs. Don’t skimp on this; your lungs will thank you.

- Gloves: Shields your hands from chemicals and abrasions. A good pair of gloves can make all the difference.

- Protective Clothing: Wear long sleeves and pants to prevent skin contact with chemicals. Old clothes work, but make sure they cover you well.

- Steel-Toed Boots: Protect your feet from heavy tools and materials. Better safe than sorry if something drops.

Pro tip: Choose PPE that fits well and is comfortable to wear for extended periods. If it’s uncomfortable, you’re less likely to wear it, and that’s when accidents happen.

Handling Tools and Chemicals

When you’re working with microtopping, having the right tools and handling chemicals safely is crucial. These tools make the job easier and ensure a smooth, even finish. Here’s what you’ll need and how to handle them smartly.

- Mixing drill: Essential for blending microtopping mix uniformly. Use a low-speed setting to avoid air bubbles.

- Trowel: Key for applying the microtopping evenly. Opt for a stainless steel one to prevent rusting.

- Protective gloves: Always wear these to protect your skin from chemicals. Nitrile gloves are a good choice.

- Respirator mask: Protects your lungs from dust and fumes. Don’t skip this; safety first.

- Goggles: Shields your eyes from splashes. Comfortable fit is important for long use.

- Measuring bucket: Ensures accurate mixing ratios. Use a clear one to see the levels easily.

Pro tip: Invest in quality tools. Cheap substitutes can break or give uneven results, costing you more in the long run.

Cost Analysis of Tools and Materials

This section offers a detailed breakdown of the expenses involved in acquiring the necessary tools and materials for microtopping preparation. By understanding these costs, you can effectively budget your project and ensure you have all the essential components for a successful application.

Cost-Effective Tool Selection

Selecting the right tools is crucial for any project. You want tools that do the job well without breaking the bank. It’s all about finding that sweet spot between cost and quality.

- Hammer drill: Essential for drilling into concrete or brick. Look for one with variable speed settings for better control.

- Cordless screwdriver: Perfect for assembling furniture or light fixtures. Choose one with a good battery life to avoid constant recharging.

- Adjustable wrench: Great for tightening or loosening nuts and bolts. A sturdy one will last longer and save you from buying replacements.

- Measuring tape: Accurate measurements are key. A lockable tape ensures precision and ease of use.

- Utility knife: Handy for cutting various materials. Opt for one with replaceable blades to keep it sharp.

Pro tip: Always test tools in-store if possible. A quick feel can tell you a lot about their quality and comfort in your hand.

Knowing When to Call in the Pros for Microtopping

While DIY microtopping projects can be rewarding, certain situations demand professional expertise to ensure a successful outcome. Recognizing when to seek professional help can save you time, money, and potential frustration. Here are key scenarios where turning to a professional is advisable:

- If the surface area is extensive or involves complex patterns, a professional can ensure uniform application and avoid inconsistencies.

- When dealing with surfaces that have significant damage or require structural repairs, expert intervention is crucial for a stable base.

- If you lack the necessary tools or equipment, hiring a professional can be more cost-effective than purchasing high-end machinery for a one-time project.

- For projects with tight deadlines, professionals can expedite the process with their experience and resources, ensuring timely completion.

- When specific aesthetic outcomes are desired, such as custom finishes or intricate designs, professionals can deliver precision and artistry.

- If you encounter unexpected issues during the project, such as moisture problems or adhesion failures, a professional can troubleshoot effectively.

- For projects requiring compliance with local building codes or regulations, professionals can navigate these requirements seamlessly.

Assessing Project Complexity

Before beginning a microtopping project, evaluate the complexity of the task. Consider the size, condition, and desired finish of the surface. Complex projects often benefit from professional oversight to ensure quality and durability.

Budget Considerations

While DIY can be cost-effective, unexpected challenges can inflate expenses. Weigh the potential costs of mistakes against the investment in professional services to make an informed decision.

Common Mistakes and How to Avoid Them

Common mistakes in microtopping prep include inadequate surface cleaning and improper mixing ratios, which can lead to poor adhesion and finish. By understanding these pitfalls and implementing effective solutions, you can ensure a smooth and durable microtopping application.

Misjudging Surface Conditions

Before you start any project, make sure you know what you’re working with. Surface conditions can make or break your efforts. First, always check base compaction. If the ground isn’t solid, your work will shift or settle over time. Use a tamper or roller to ensure it’s packed tight.

Next, assess moisture levels. Too wet, and you’ll end up with a soggy mess. Too dry, and materials may not adhere properly. Aim for a happy medium. A simple hand test can tell you a lot: grab a handful of soil or material, squeeze it, and see if it holds shape without crumbling or dripping.

Finally, don’t ignore slope and drainage. Poor drainage leads to water pooling, which can ruin your work. Make sure the surface slopes away from structures to direct water flow properly. A little planning here saves a lot of headaches down the road.

Incorrect Tool Usage

Using the wrong tools can turn a simple job into a nightmare. The right tools make the work easier, faster, and safer. Using the wrong ones can damage materials or even cause injuries.

- Hammer drill: Essential for drilling into concrete or brick. Don’t use a regular drill for this, or you’ll end up frustrated and with a burnt-out motor.

- Level: Keeps everything straight and aligned. A crooked shelf isn’t just ugly; it’s a hazard.

- Utility knife: Perfect for cutting drywall or carpet. A dull blade will slow you down and can lead to accidents.

- Stud finder: Finds the support behind walls. Don’t guess and end up with a hole in the wrong place.

- Adjustable wrench: Versatile for various nuts and bolts. Using the wrong size wrench can strip them and make your life miserable.

Pro tip: Invest in quality tools. Cheap ones break easily and can cost more in the long run. Always test your tools before heading to the site to ensure they’re in good working condition.

Environmental Considerations and Sustainable Practices

Environmental considerations and sustainable practices in surface preparation focus on reducing ecological impact while maintaining efficiency. By adopting eco-friendly methods, industries can minimize waste, lower emissions, and promote long-term environmental health.

Eco-Friendly Materials

Using eco-friendly materials in microtopping applications not only benefits the environment but also enhances the quality and durability of your project. Here’s what you need to get started.

- Recycled Aggregates Opt for aggregates made from recycled materials to reduce waste and lower environmental impact.

- Low-VOC Sealers Choose sealers with low volatile organic compounds to ensure better indoor air quality and a healthier environment.

- Water-Based Pigments Use water-based pigments for coloring. They are less harmful and more sustainable than solvent-based options.

- Natural Fibers Incorporate natural fibers for reinforcement. They are biodegradable and improve the strength of the microtopping.

- Eco-Friendly Binders Select binders that are labeled as environmentally friendly to minimize the carbon footprint of your project.

Pro tip: Always check for certifications like LEED or Green Seal to ensure the materials truly meet eco-friendly standards.

Conclusion

Getting microtopping right on polished surfaces isn’t just about slapping on a coat and hoping for the best. You need to know your concrete’s hardness and choose the right tools for the job. Skipping these steps can lead to a weak finish that won’t last. Trust me, taking the time to understand these factors pays off in the long run.

Don’t underestimate the importance of proper surface preparation and cleaning. A clean, well-prepared surface is your best friend. This isn’t just about looks; it’s about making sure your microtopping sticks and stays put. And remember, safety first. Cutting corners on safety can cost you more than just money.

Finally, think about the environment. Use sustainable practices and materials whenever possible. It’s not just good for the planet; it’s smart for your wallet too. Avoid common mistakes by planning ahead and doing things right the first time. Your polished surface will thank you for it.

FAQ

What is microtopping?

Microtopping is a thin layer of cement-based coating applied to surfaces. It gives floors a fresh, modern look without the need for a full replacement.

Why do I need a scratch profile on polished surfaces?

A scratch profile helps the microtopping adhere better to the surface. Without it, the microtopping might peel or not stick properly.

Can I skip the scratch profiling step?

Skipping the scratch profiling is a bad idea. The microtopping won’t hold well, and you’ll end up with a mess that needs fixing later.

What tools do I need for creating a scratch profile?

You need a grinder or a sander with the right grit. Make sure to use the proper safety gear to protect yourself from dust and debris.

How do I know if I’ve done the scratch profile correctly?

The surface should feel rough to the touch, like sandpaper. If it’s smooth, you need to go over it again until it’s properly scuffed up.