Introduction

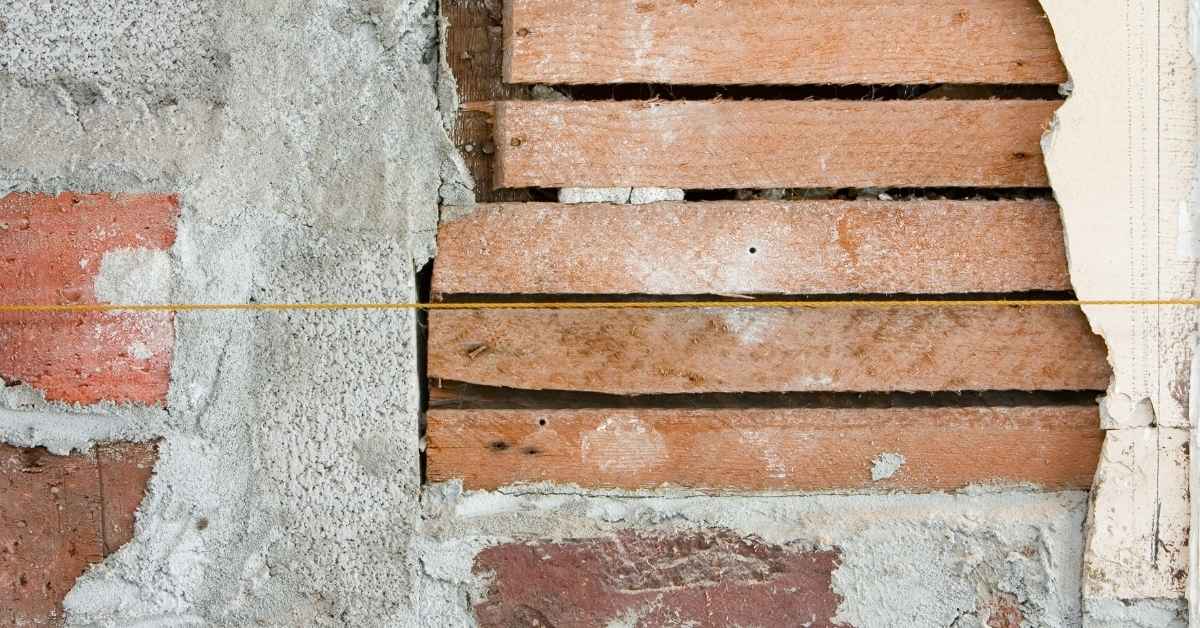

Repairing plaster where lath is loose means choosing between refastening the existing lath and replacing damaged lath.

This article helps you decide which path fits your wall and how to do it safely.

It keeps things practical and ready for a DIY project, not a textbook.

To decide, start by locating loose lath and assessing plaster damage.

If the lath is solid enough and the edges can be re-secured, refastening is a lower‑risk option; if the lath is rotten or cracked, replacement may be required.

Always check the product labels, manufacturer instructions, and any local rules for acceptable fasteners and repair methods.

Key takeaways

- Identify loose lath by tapping; hollow or rattling plaster signals failure.

- Assess whether refastening or replacing is safer and more durable.

- Secure lath with proper fasteners perpendicular to studs and framework.

- When replacing, remove damaged plaster and lath sections carefully to avoid dust.

- Match plaster type and lath spacing to existing wall for compatibility.

- Safety: wear eye protection, mask dust, and contain debris during repairs.

Table of Contents

- Introduction

- Key takeaways

- When to Refasten Vs When to Replace

- How to Inspect Loose Lath and Plaster

- Tools and Materials Checklist

- Refastening Lath: Step-by-Step Method

- Replacing Lath or Removing Plaster: Methods and When to Use Them

- Preventing Future Problems

- Costs, Time, and Environmental Impact

- Common Mistakes and Troubleshooting

- Conclusion

- FAQ

When to Refasten Vs When to Replace

The decision rests on damage extent, lath type, and the plaster’s bond to the lath. Start by assessing whether the plaster is simply loose or if the lath is damaged or decayed. Also check for contamination risks like lead paint, mold, or asbestos before choosing a repair path. Use prompts from product labels or manufacturer instructions to verify compatibility and safety steps.

A practical workflow helps you decide: identify minor loose plaster that can be refastened, moderate delamination that suggests partial replacement, or extensive deterioration that calls for full section replacement. Evaluate the structural role of the wall and moisture careers that may undermine fixes. And always document findings to guide sequencing, materials, and any needed permits or professional help.

Damage assessment criteria

First, check the plaster for delamination – where it’s peeling away from the lath. If it’s minor and localized, refastening might work.

Next, examine the lath itself. If it’s wood and rotting or metal and rusted, replacement is likely needed.

Assess how far the loose areas spread. If it’s just a small section, refasten. But if it’s widespread, consider full replacement.

Structural and safety considerations

Look for sagging or bulging plaster. This could mean compromised framing or structural issues, requiring replacement.

Check for cracks spreading out from the loose area. This indicates a bigger problem that can’t be fixed by just refastening.

If you find hollow-sounding plaster, there might be moisture intrusion behind it. Replace to prevent further damage and mold growth.

Longevity and reuse factors

The age of your plaster and lath matters. Older materials might not hold up well with refastening, making replacement a better choice.

Previous repairs can also affect durability. If the area has been patched before, it might be best to replace rather than risk further issues.

Moisture history is crucial. If the area has had repeated exposure to water, refastening might not last long. Consider replacing for a longer-term solution.

How to Inspect Loose Lath and Plaster

This section guides a room-by-room survey from safe access points. Establish scope, safety checks, and a step-by-step plan before disturbing any plaster. Keep notes handy on what you see and feel as you go. If you’re unsure about hazardous materials, consult the product label, manufacturer guidance, or local regulations for testing and handling.

Document visual and tactile cues like cracks, sagging sections, hollow sounds, nail pops, or soft walls. Look behind the plaster for missing or damaged lath, rusted nails, or moisture signs. Create a labeled map with photos and basic measurements to support a clear severity scale and next steps.

Step-by-Step Process

This section guides you through inspecting loose lath and plaster, ensuring a thorough and safe assessment.

- Preparation: Gather your tools (flashlight, straightedge, mirror, magnet, moisture meter, stud finder) and safety gear (PPE). Consider lead paint or asbestos precautions in older homes.

- Safety checks: Turn off power to the room at the main electrical panel. Check for any signs of structural instability before proceeding.

- Establish scope: Start from one corner, work your way around the room, and document each wall systematically.

- Main survey: Tap walls with a straightedge or knuckle, listen for hollow sounds, and look for cracks, sagging, or nail pops. Use your mirror to check hard-to-reach areas.

- Documentation: Photograph hotspots, measure their distance from ceiling/floor, height, and note severity (stable, loosely attached, detached).

Visual and Tactile Checks

Inspecting loose lath and plaster involves careful observation and gentle probing to avoid causing further damage.

Start by tapping the wall with a straightedge or knuckle, listening for hollow sounds that indicate loose lath. Be gentle – you’re not trying to knock it down!

Look for cracks, especially those running horizontally or at nail heads, which suggest loose lath. Also, check for sagging plaster or walls that feel soft or move with pressure.

Use your mirror to inspect hard-to-reach areas and take photos of any hotspots you find. These will help you map the problem areas and track progress later.

Probing and Mapping Problem Areas

Once you’ve identified loose areas, carefully probe them to determine the extent of delamination. This helps plan your repair or replacement work.

Use a straightedge to gently press along cracks or suspected loose areas. If it sinks in more than 1/8 inch, the lath is likely detached.

Gently probe with a flathead screwdriver or awl at nail heads and other suspect spots. Be careful not to push too hard and cause further damage. Mark the extent of delamination on your room map.

If you find large sections that are completely detached, it may be more cost-effective to replace the lath rather than refasten it. This is where your documentation comes in handy for planning next steps.

Hidden Hazards to Watch For

Before you start any repair work, be aware of potential hidden issues behind the walls. These can pose safety risks or complicate your repairs.

Use a stud finder to locate and mark studs. Avoid probing or cutting into them unless necessary, as they may hide wires or plumbing.

Check for signs of moisture, mold, or plumbing leaks. These can cause lath to rot or become loose and should be addressed before any repair work.

If you suspect asbestos, lead paint, or other hazardous materials, do not disturb them. Hire a licensed professional to handle these safely. Also, consider calling an electrician if you find exposed wires or need to move outlets.

Tools and Materials Checklist

List essential tools and PPE you’ll actually use: hammer, pry bar, putty knives, drill with masonry bits, screws, anchors, plaster washers, pliers, and a small shop vacuum. Include safety gear like goggles, a dust mask, and gloves. Have a moisture meter handy for detecting lingering dampness in walls.

Decide on fastening options based on lath condition: wood screws into existing lath, masonry anchors, toggle bolts, or plaster washers. Gather patch materials such as lime-putty, cementitious mortars, bonding agents, mesh or new metal lath, and patch or joint compounds. Don’t forget a simple prep kit to clean dust and inspect for moisture or mold.

Fastening tools and anchors

Use this checklist to ensure you have the right fasteners for your repair job.

- Wood screws: Use for refastening lath into existing wood framing. Check packaging for length and gauge suitable for your lath thickness.

- Masonry anchors: For refastening lath to concrete or brick walls. Ensure they’re rated for your wall’s load-bearing capacity.

- Toggle bolts: Use when lath is loose but wall material is too soft for anchors. Check packaging for suitable wall materials.

- Plaster washers: Use with screws to distribute pressure and prevent plaster from cracking. Ensure they’re the right size for your screw heads.

- Drill/driver: Check it has a masonry bit set for drilling into concrete or brick.

- Pry bar: Useful for removing old fasteners and exposing damaged lath. Be careful not to damage surrounding plaster.

- Hammer: For tapping in toggle bolts and setting screws. Avoid over-tightening to prevent damaging lath.

- Pliers: Helpful for gripping and turning toggle bolt wings once inserted into the wall.

Quick rule: Always check manufacturer guidelines to ensure fasteners are suitable for your specific repair situation.

Plaster and bonding materials

Use this checklist to choose the right materials for your plaster repair job.

- Patch plaster: Suitable for small gaps. Check if it’s compatible with your existing historic plaster type.

- Lime-putty: For fine cracks and small repairs. Ensure it’s suitable for your climate and wall conditions.

- Cementitious repair mortars: Ideal for larger patches. Check they’re compatible with your existing plaster and can match its finish.

- Bonding agents: Use to improve adhesion between new and old plaster. Ensure they’re suitable for your specific plaster type.

- Plaster mesh: For reinforcing large patches or replacing damaged lath. Check it’s compatible with your repair material.

- Metal lath replacement: Use when lath is severely damaged. Ensure it’s the right gauge and size for your wall.

- Joint/patch compounds: For finishing repairs. Choose one that matches your existing plaster’s texture and color.

Quick rule: Always test materials on a small, hidden area first to ensure compatibility with your existing plaster.

Safety gear and cleanup supplies

Use this checklist to protect yourself and others during the repair process.

- Goggles: Protect eyes from dust and debris. Ensure they fit well and provide full coverage.

- Dust mask: Essential for protecting lungs from plaster dust. Choose one rated for particulate filtering.

- Gloves: Protect hands from cuts, scrapes, and chemicals. Choose a pair that fits well and allows good grip.

- Shop vacuum: Use to clean up dust and debris. Ensure it has a HEPA filter for better dust containment.

- Drop cloths: Protect floors and furniture from dust and plaster chips. Secure them with tape if necessary.

- Disposal bags: Seal and dispose of waste materials properly to prevent contamination and injury.

Quick rule: Always prioritize safety over speed. Take your time to ensure a safe working environment.

Refastening Lath: Step-by-Step Method

Start with safety and assessment: mark all loose lath sections and note moisture or ghost cracks. Decide whether lath is salvageable or if partial replacement is needed. Be aware of any asbestos risk in very old homes and plan accordingly. Check local guidance for handling hazardous materials.

Next, gather your pre-work items and protect surfaces. Temporarily stabilize plaster, then secure exposed edges with appropriate fasteners. Use plaster washers or furring strips to straighten wavy lath and prepare for reattachment. Then proceed with the refasten process, avoiding plaster pop and using the right bonding agents when indicated.

Step-by-Step Process

This step-by-step guide walks you through refastening loose lath, ensuring a solid and lasting repair.

- Safety first: Put on gloves, goggles, and a dust mask. Inspect the area for asbestos or other hazards.

- Assess damage: Identify all loose sections, check for cracks, and note any moisture damage. Mark areas needing partial replacement.

- Prepare the workspace: Protect floors and furniture. Gather tools and materials listed earlier.

- Main work: Stabilize plaster temporarily, secure lath edges with fasteners, and support wavy or bowing lath using furring strips or washers.

- Refasten lath: Drive fasteners carefully to avoid popping plaster. Use modern fasteners or nail plates. Apply bonding agent where needed.

- Restore plaster: Reattach fragments, apply keys or skim coats, feather edges, and test for soundness. Address recurring cracks.

- Quality check: Allow curing time, consider moisture levels, prep for painting, and ensure long-lasting adhesion.

Preparing the substrate

Properly preparing the lath and plaster edges ensures strong bonds with fasteners and adhesives.

First, remove any loose or crumbling material using a trowel. Be gentle to avoid damaging the surface further.

Next, dry the area thoroughly. Use fans or dehumidifiers if necessary. Moisture weakens adhesion.

Finally, score the plaster edges lightly with a trowel or knife to create better bonding surfaces for the new plaster and fasteners.

Fastening technique and anchoring strategy

Proper anchoring prevents future failures. Here’s how:

When refastening, drive fasteners at an angle to avoid splitting the lath. Aim for a 45-degree angle.

Use modern fasteners or nail plates. They provide better grip and prevent future failures.

If lath is wavy or bowing, use furring strips or plaster washers as backing. This provides a solid surface for refastening.

Repairing the plaster surface and finishing

After refastening, restore the plaster surface to match the surrounding texture:

Apply scratch and finish coats. Use a trowel or hawk for even application.

For cracks, use joint compound. Apply in thin layers, allowing each to dry before sanding lightly. Reinforce wide cracks with mesh tape.

To blend patches, feather the edges of your repairs into the surrounding plaster using a damp sponge or trowel. This helps disguise repair lines.

Replacing Lath or Removing Plaster: Methods and When to Use Them

Decide between partial removal and full strip-and-replace by evaluating lath condition, plaster bond, and moisture exposure. Consider how the wall supports load and whether replacement will improve long-term performance. Check for lead or asbestos and follow proper containment and disposal rules per local requirements. Verify product instructions for compatibility with the chosen path.

Outline the methods: partial removal to access and repair damaged zones, or full strip-and-replace with new lath and plaster or a modern drywall system. Explore converting to drywall over lath or skim coatings as alternatives, weighing pros and cons. Ensure you follow safety and code guidance when planning demolition and substrate work.

Partial vs Full Replacement Decision

When deciding between partial removal and full strip-and-replace, assess the existing lath and plaster condition.

Partial Removal: Choose this when damage is localized. Accessibility to the affected areas is key. If you can safely reach and repair the damaged sections without disturbing surrounding good lath, partial removal is your best bet.

Full Strip-and-Replace: Opt for this when extensive damage or moisture issues are present. It’s also necessary if structural implications arise from probing and mapping problem areas (as discussed earlier).

Installing New Lath or Modern Backings

When replacing old lath, consider these options:

Wood Lath Replacement: If your existing lath is wood, you might choose to replace it with new wood lath. Ensure the new lath matches the size and spacing of the original.

Metal Lath: For a more durable option, consider metal lath. It’s less prone to rot and warping but can be noisier due to its thin profile.

Rigid Backing/Drywall: If you’re converting to modern finishes, install a rigid backing or drywall directly over the existing lath. This method requires checking for proper support and ensuring the lath is secure before proceeding.

Replastering vs Switching to Drywall

Aesthetics, performance, and cost are key factors when deciding between replastering and switching to drywall.

Replastering: Restoring traditional plaster finishes maintains the historic character of your home. It’s ideal for preserving architectural details but can be labor-intensive and costly.

Switching to Drywall: Drywall is faster, cheaper, and easier to install than plaster. It provides better insulation and soundproofing but lacks the aesthetic appeal and durability of traditional plaster.

Consider your budget, timeline, and desired outcome when making this decision. Both options require proper prep work and may necessitate addressing hidden hazards (as discussed earlier).

Preventing Future Problems

Identify moisture and leak sources that drive plaster delamination and plan mitigation accordingly. Consider interior humidity control, roof and drainage fixes, and flashing where needed. Look at ventilation improvements to reduce constant moisture exposure on plaster surfaces. Rely on manufacturer or code guidance when tackling moisture-related fixes.

Outline structural reinforcement and attachment best practices to stop future loosening. Use proper stud and lath repair, correct fastener spacing, and appropriate backing or metal lath where required. Create a simple maintenance plan with seasonal inspections and a clear decision path for patching, reinforcing, or full lath replacement based on age and moisture exposure.

Moisture and ventilation control

Controlling moisture is key to preventing loose lath. First, find leak sources – roof, plumbing, or exterior walls. Fix leaks promptly.

Interior humidity: Use exhaust fans in bathrooms and kitchens. Consider a dehumidifier if needed. Keep humidity below 50%.

Roof and flashing: Inspect roof regularly. Repair any damaged shingles or flashing to prevent water intrusion.

Improve drainage around your home’s foundation to keep moisture away from walls. Ensure gutters are clean and direct water away from the house.

Structural reinforcement and load considerations

If lath loosened due to structural movement or overstressed members, reinforce framing. Tighten any loose studs with a framing nailer.

Load redistribution: If one area is overstressed, redistribute loads by adding support beams or sistering joists.

Use proper fasteners and spacing when refastening lath. Consider using backing or metal lath for added support where needed.

If movement persists, consult a structural engineer to assess if additional reinforcement is required.

Maintenance and monitoring tips

Inspect your plaster walls seasonally. Check for cracks, bulges, or moisture signs like discoloration or musty odors.

Early signs: Small hairline cracks may indicate bigger issues. Address them promptly to prevent worsening damage.

Keep an eye on areas near plumbing fixtures, chimneys, and exterior walls that are prone to moisture intrusion.

Create a simple remediation checklist for easy reference when minor repairs are needed. Regular maintenance will help catch problems early before they become major issues.

Costs, Time, and Environmental Impact

Consider cost drivers like plaster mix, patching compounds, and lath replacement, plus fasteners and reinforcing mesh. Expect differences between refastening and replacement, but verify material specs and installation conditions with the product data sheets or manufacturer instructions. Local rules may affect disposal and containment, so confirm requirements before starting.

Assess labor time and sequencing for each approach, including prep, removal, lath assessment, application steps, curing, and cleanup. Weigh environmental impacts by looking at waste, recycling options, and dust containment practices. Use a quick reference checklist to minimize costs and time while meeting safety and code expectations.

Comparing cost drivers and timelines

The price and duration of your repair depend on several factors. First, scope: partial repairs are cheaper but full replacement might be necessary for long-term durability.

Access also matters. Hard-to-reach areas take longer and cost more. Contaminants like lead paint increase labor costs due to safety measures.

Specialist trades may be needed, like plasterers or structural engineers, adding to the bill. To get accurate estimates, get quotes from multiple professionals, clearly outlining the work you want done.

Waste, recycling, and material choices

Material choices impact your repair’s success and environmental footprint. Here are some options to consider:

- Salvage historic lath and plaster: If possible, reuse old materials to reduce waste. Ensure they’re in good condition.

- Recycle plaster debris: Many recycling centers accept plaster for reuse or safe disposal.

- Use eco-friendly fasteners: Choose screws made from recycled materials or sustainable sources.

- Consider modern plasters: Some are more durable and easier to apply, reducing long-term waste.

- Avoid low-quality materials: Cheap plasters may crack or stain, leading to early replacement.

Common Mistakes and Troubleshooting

Be wary of repeating failures: neglecting moisture sources, patching without addressing loose lath, and using inappropriate fasteners. Inspect patch material compatibility and ensure proper surface prep for lasting adhesion. Review product labels or manufacturer guidance to avoid mismatches in plaster type or substrate.

Validate plaster and lath condition before patching by testing soundness, checking for rust or rot, and confirming no hidden water damage. Follow best practices for fastening and patching, and note cure behavior to catch early cracks or re-delamination. If repairs fail, remove the patch, re-anchor or re-lath as needed, and adjust your method, with moisture control as a key preventive measure.

Avoiding over-fastening and cracking

Using too many fasteners or the wrong type can cause more harm than good. Here are some mistakes to avoid:

- Too many screws: Over-fastening can crack the plaster. Use just enough to secure the lath.

- Incorrect screw size: Too small and they won’t hold; too large and they’ll split the lath.

- Wrong fastener type: Drywall screws aren’t suitable for lath. Use appropriate plastering screws or nails.

- Fastening through rusted lath: This can cause further damage. Replace rusted lath before refastening.

If cracking appears, remove the fasteners, clean the area, and reattach using proper technique.

Adhesion and material mismatch issues

Choosing the right materials is crucial for a successful repair. Here’s what to look out for:

- Incompatible patch material: Using drywall mud on lath can cause cracking. Use plaster of Paris or joint compound designed for lath.

- Wrong mixing ratio: Incorrectly mixed materials won’t adhere properly. Follow the manufacturer’s instructions.

- Poor surface prep: Dust, grease, or old paint can weaken adhesion. Clean and sand the area before patching.

- Incompatible primer: Using a primer not designed for plaster can cause staining or weak bond.

If you notice cracking, staining, or weak bonds after patching, remove the failed patch, clean the area, and reapply with appropriate materials and technique.

When to call a professional

Some plaster repair jobs are best left to the pros. Here’s when to seek help:

Structural concerns: If you suspect structural damage, such as sagging walls or bulges, stop work and contact a structural engineer or architect.

Hazardous materials: Asbestos in old plaster should be handled by licensed professionals to ensure safe removal.

Complex rewiring: If your repair involves moving or adding electrical outlets or switches, hire a licensed electrician for safety and code compliance.

To find qualified help, ask friends for referrals, check online reviews, and always verify licenses and insurance before hiring.

Conclusion

The core idea is simple: fix the loose lath or plaster with a safe, deliberate plan now to protect structure, appearance, and future durability. If you choose refastening, you keep the wall true; if the lath or plaster is too damaged, replacement is warranted to prevent repeat failures and costly pulls later.

Start by inspecting a small, reasonable area and decide if the lath is truly loose or if the plaster just needs a firm reattachment; then test for movement by gentle pressure, gather the tools and materials you identified in the checklist, begin with the refastening steps on secure areas first, and only move to replacement if you find cracks or hollow spots that won’t tighten up, while keeping dust control, clean work surfaces, eye and mask protection, and consistent moisture checks as you go.

Common mistakes to avoid are overdriving fasteners or forcing lath into place when it’s still loose, prying or hammering without backing to prevent cracking, and ignoring moisture or permitting ongoing leaks; always pause if you see water intrusion, test repairs in a small area first, and never skip safety gear or proper dust containment.

When a repair would require extensive backing, rotten lath, or repeated failures in the same area, consider bringing in a pro rather than pushing ahead alone; otherwise, stay disciplined, follow the plan, and you’ll finish with a solid, lasting wall you can trust. You’ve got this—take it step by step and keep the work clean, careful, and reversible where possible.

FAQ

How can I identify loose lath in plaster walls?

Tap the wall and listen for hollow or dull sounds. Look for sagging plaster, cracks that run unevenly, or pops when you press lightly. Poking with a thin tool can reveal loose edges behind the plaster.

What techniques work best for refastening loose lath?

Use appropriate fasteners to bite into solid framing and pull the lath tight against the studs. Put clean, firm bites with corrosion-resistant screws or nails and stagger the nails to avoid splitting. Don’t overdrive; you want the lath snug, not crushed.

What steps should I follow to replace damaged lath and plaster?

Carefully remove the damaged area to expose solid wood behind. Cut new lath to fit and attach it securely, then reapply plaster or plaster patching compound in thin layers. Feather edges smooth and let each layer set before the next.

What materials and tools should I have on hand before starting?

Leather gloves, safety goggles, a pry bar, hammer, pry knife, and a stud finder are essential. Have proper fasteners, plaster patch mix or compatible plaster, and suitable bonding agents ready. Check manufacturer instructions and local guidelines for any material-specific notes.