Introduction

Repairing plaster after removing tile means leveling the wall, applying a bonding layer, and getting it ready for plaster.

Start by cleaning the surface, removing tile film, and filling any gouges or ridges to create a flat base. Then identify high spots and plan to flatten them with gentle passes and proper feathering of patches.

Use a suitable bonding technique to stick plaster over tile residue, following the product label and manufacturer instructions. Prime the bare spots if required, and embed a patch or mesh as needed to bridge cracks and control movement. Keep joints and edges feathered and monitor for any cracks as it cures, checking local guidelines for drying times.

Key takeaways

- Inspect substrate for cracks, moisture damage, or delamination before plastering.

- Wear eye protection and respirator; control dust when removing tile adhesive.

- Scrape or grind tile residue clean, avoiding gouges that jeopardize plaster adhesion.

- Level uneven areas with careful skim coats, addressing high spots first.

- Bond plaster over residue with a compatible bonding agent following manufacturer instructions.

- Use reinforcement and proper finishing to reduce future cracks and movement.

Table of Contents

- Introduction

- Key takeaways

- Safety and Pre-Work Checks

- Removing Tiles and Adhesive Without Damaging the Substrate

- Inspecting and Diagnosing the Exposed Substrate

- Surface Preparation to Ensure Good Plaster Bonding

- Choosing the Right Plaster and Reinforcement Products

- Mixing and Applying Plaster to Flatten and Finish

- Reinforcement and Strategies to Prevent Future Cracks

- Drying, Finishing, Maintenance, and Long-Term Durability

- Conclusion

- FAQ

Safety and Pre-Work Checks

Before you touch tile or plaster, take a careful look around the work area. Identify hidden hazards and plan controls to protect people and property. Document any signs of moisture or mold that could affect bonding and indoor air quality.

Wear the right PPE and establish clear rules for entry and containment. Check utilities and nearby structures to ensure isolation or safeguarding measures are in place. Plan for proper ventilation, dust control, and a clean, organized workspace to keep everyone safe through the job.

Identify hazards (asbestos, electrical, plumbing)

Before you start removing tiles, it’s crucial to identify any potential hazards in the work area. This includes suspect materials like asbestos, live wiring, or hidden plumbing.

Asbestos: If your home was built before 1980, there’s a chance it contains asbestos. Look for old insulation, vinyl floor tiles, and adhesives. If you’re unsure, stop and get professional testing done.

Electrical hazards: Before removing tiles, turn off the power at your main electrical panel. Test wires with a non-contact voltage tester to ensure they’re dead before working on them. If you find live wiring or aren’t sure, call an electrician.

Plumbing hazards: Before removing tiles, locate and mark any plumbing lines behind the wall. Be careful not to puncture them during removal. If you’re unsure about their location, consider using a plumbing snake or calling a professional.

Personal protective equipment and dust control

Protecting yourself and containing dust are key to a safe and clean tile removal project.

- Dust mask/respirator: A N95 or P100 respirator is crucial for protecting against plaster dust. Consider renting a $20-30 HEPA-filter vacuum to keep dust levels down.

- Eye protection: Wear safety glasses with side shields or goggles to protect your eyes from debris and dust.

- Gloves: Use work gloves to protect your hands from sharp edges and chemicals in adhesives. $5-10 will get you a good pair.

- Durable footwear: Wear sturdy boots or shoes with good traction to prevent slips and falls on wet surfaces.

- Plastic sheeting: Use $10-20 per roll of plastic drop cloths to contain dust and protect floors. Tape them down at the edges to create a barrier.

- Ventilation: If possible, open windows or use fans to ventilate the area. This helps reduce dust levels and keeps you comfortable while working.

Removing Tiles and Adhesive Without Damaging the Substrate

Start by confirming the tile type and substrate condition to choose the gentlest removal method. The goal is to minimize damage while lifting the tile and adhesive. Consider how different materials respond to mechanical and chemical approaches.

Protect surrounding surfaces and utilities as you work. Manage dust with barriers and enclosures, and choose methods that reduce impact on plaster or board beneath. Identify adhesive residues and plan the proper steps to surface readiness for bonding later.

Tile removal techniques by tile and installation type

First, figure out your tiles. Ceramic and porcelain are tough, natural stone can be fragile.

Ceramic/Porcelain: Use a chisel with a flat blade. Tap gently, work from corner to center. Don’t gouge the wall.

Bonded tiles (like mosaic): Use a power tool like an oscillating multi-tool. Go slow, follow tile lines. Keep it steady.

Removing thinset, mastic, and grout residues

Start with mechanical removal. Use a scraper or grinder for tough spots.

Thinset: It’s hard. You might need to grind it off. Be patient, go slow.

Mastic: Softer. Scrape it off. If it’s stubborn, use a chemical remover.

If you can’t get it all off, key the residue. It’ll help your new plaster bond better.

Inspecting and Diagnosing the Exposed Substrate

Clarify what you are inspecting by separating surface finishes from the actual substrate behind removed tile. Determine whether you are dealing with plaster, board, concrete, or masonry and how findings steer the repair plan. Document the current state for accuracy.

Look for moisture, hollow areas, and signs of deterioration. Check for delamination, crumbling edges, and backing failures that could influence bonding and strength. Note any contamination that could hinder the next coat or patching effort.

Common substrate types and their behaviours

The first step is to identify what’s behind your removed tiles. Each type has its own bonding quirks:

Brick: Absorbs moisture, so it needs a damp-proof membrane before replastering.

Cement backer board: Provides a solid base but can be porous; seal before applying new plaster.

Original plaster: Bonds well with new plaster. Remove loose bits and clean before starting.

Drywall (plasterboard): Needs screws tightened, holes filled, and a primer coat for better bonding.

Detecting damp, salts, and structural movement

Check for moisture and salt contamination:

Look for staining, damp patches, or efflorescence. Use a surface moisture meter to confirm.

Tap the wall. A hollow sound could mean movement or delamination, needing repair before replastering.

Check for peeling paint/wallpaper and obvious leaks/condensation sources.

Surface Preparation to Ensure Good Plaster Bonding

Verify that the surface left by tile removal is clean, sound, and ready for bonding. Flag any cracked areas, adhesive residues, or moisture problems that could undermine adhesion. Plan targeted repairs before applying plaster.

Clean thoroughly to remove dust and oils, and create a mechanical key without gouging the substrate. Address moisture and porosity with appropriate treatments and primers to improve bond and prevent future cracks. Choose bonding agents and renders compatible with the post-tile surface and follow best practices for application.

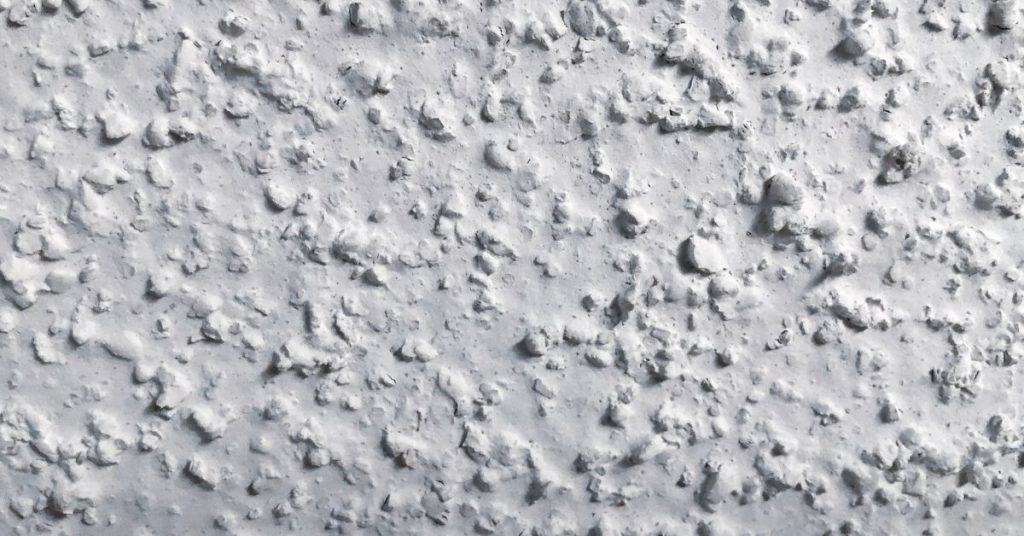

Cleaning, keying, and priming (PVA, bonding slurry)

Before you start, ensure the surface is clean. Use a neutral detergent and stiff brush to remove dust, oils, and old adhesive residues. Vacuum thoroughly afterwards.

Mechanical keying roughens the surface for better plaster adhesion. You can use a scraper, sander, or wire brush. Be careful not to gouge or expose the substrate.

For PVA priming, apply it evenly with a paintbrush or roller. Let it soak in, then wipe off excess with a damp cloth. For bonding slurry, mix according to instructions and apply like PVA.

When to install an insulating or backing layer first

If the substrate is uneven, damaged, or has moisture issues, consider installing a backing layer before plastering. This could be plasterboard, cement board, or render.

Plasterboard provides thermal and acoustic insulation. It’s ideal for interior walls with high humidity or noise levels. Cement board is suitable for wet areas like bathrooms, providing a stable base for tiling.

Render can be used as a backing layer on exterior walls. It helps to even out the surface and provides some insulation. Always ensure your chosen backing layer is compatible with your plaster type and application method.

Choosing the Right Plaster and Reinforcement Products

Assess the substrate condition after tile removal, noting plaster type, board backing, and any lingering moisture. Decide if repairs are needed before plastering to ensure a solid bond. Identify the best plaster approach for the space you are working in.

Compare options such as gypsum skim or cement-based patches and ready-mix formulations. Match reinforcement with substrate behavior, whether mesh, scrim, or bonding agents, to improve adhesion and crack resistance. Prepare the surface with proper priming and cleaning to support the chosen materials.

Plaster types and where to use them

Choose the right plaster for your job. Here’s what you need to know:

Gypsum Skim: Ideal for smooth, interior dry walls. It’s quick-setting and easy to apply. Use it when you want a fast turnaround.

Lime or Cement-based Patching: These are great for repairs where strength is needed. They’re slower setting but provide excellent adhesion over old plasterwork. Use them for heavy repairs or damp-prone areas.

Ready-mix Formulations: These offer quick, consistent coverage. They’re perfect when you need to cover a large area fast. Keep in mind they might have longer curing times.

Bonding agents, mesh, and reinforcement options

Reinforcement is key to preventing future cracks. Here are your options:

Bonding Agents: These improve adhesion over difficult substrates. Use them on old plasterwork or where you’ve removed adhesive residue.

Mesh: Mesh reinforces joints and bridges hairline cracks. It’s ideal for areas with movement or where you’ve had previous cracking issues.

Scrim: Scrim is a flexible reinforcement that can be used over large areas. It’s great for preventing future cracks on rigid substrates like concrete or brick.

Mixing and Applying Plaster to Flatten and Finish

Check substrate readiness and moisture status before mixing. Decide on the appropriate plaster type and achieve a workable consistency. Avoid mixtures that are too runny or too stiff for the job at hand.

Apply base coats and skim coats with careful technique to create a flat, even surface. Use straightedges and consistent thickness while embedding any reinforcement as needed. Finish with attention to feathering edges and curing considerations to prevent defects.

Mixing best practices and workability tips

Start by reading the manufacturer’s instructions. They know their product best. Follow their guidelines for water-to-plaster ratio.

Test your mix for workability. It should be like a soft, pliable putty – not too runny, not too stiff. Squeeze some in your hand, then open it. If it holds together but isn’t crumbly, you’re good to go.

Remember, plaster has a pot life. That means once mixed, it starts to set. So, mix only what you can use within that time.

Application sequence: base coat, float, and skim

First, apply a base coat. This is thicker, for leveling. Use your hawk to transfer plaster onto the wall, then spread it with your trowel. Aim for an even thickness.

Next, use a straightedge or darby to float the base coat. Hold it at a consistent angle and pull it across the surface in smooth, steady strokes. This flattens and evens out the plaster.

Let it set until it’s no longer sticky but still slightly damp. Then apply your skim coat. This is thinner, for the final finish. Use the same technique as the base coat, but with less plaster on your trowel.

Common finish issues and how to avoid them

Bubbles, trowel marks, and uneven texture – these are common mistakes. Let’s avoid them.

- Bubbling: This happens when air gets trapped under the plaster. To prevent it, apply your coats evenly and smoothly. If you see bubbles, pop them with a needle tool before they set.

- Trowel marks: These happen when you’re not holding your trowel at a consistent angle. Practice your technique and keep your trowel well-maintained for smooth strokes.

- Uneven texture: This can be due to applying plaster too thickly or thinly in places. Control your thickness by keeping an eye on how much you’re transferring from hawk to wall.

Remember, prevention is key. Take your time, apply evenly, and keep practicing your technique.

Reinforcement and Strategies to Prevent Future Cracks

Identify the cause and pattern of any cracks to tailor reinforcement choices. Different movement scenarios require different strategies to stay ahead of cracks. Plan for long-term stability as you select materials.

Choose appropriate reinforcement methods such as membranes, mesh, or expansion joints depending on movement. Prepare a clean, bonded substrate and select compatible bonding systems to support the reinforcement. Develop a maintenance approach to monitor and address cracks if they reappear.

Use of scrim, mesh, and movement joints

To prevent cracks from reappearing, you need to isolate stresses caused by substrate movement. Here’s how:

Scrim Tape: Apply it at the edges of your repair, where most cracking occurs. It acts like a flexible bandage, absorbing minor movements.

Fiber Mesh: Embed this in your plaster for added strength and crack resistance. Use it when you’ve got active cracks or weak substrates.

Finally, Movement Joints: Cut them into the substrate before applying plaster. They allow for expansion and contraction, preventing cracks from forming.

Addressing substrate movement and environmental causes

Understanding your substrate’s behavior is key to preventing future cracks:

Shrinkage-prone substrates: Use shrinkage-controlled, polymer-modified mortars. These have built-in flexibility to handle minor movements.

Timber framing movement: Expect some seasonal expansion and contraction. Plan for this by using flexible bonding agents and allowing for movement joints.

Also consider thermal/structural movement. In cold or hot weather, substrates expand or contract. Account for this in your repair plan.

Drying, Finishing, Maintenance, and Long-Term Durability

Outline a logical sequence that prioritizes drying and curing before finishing. Plan for surface preparation after curing and set expectations for long-term durability. Keep the project organized to support steady progress.

Manage environmental conditions to prevent rapid drying and moisture issues. Prepare surfaces for finishing with proper sanding, dust control, and priming. Choose coatings that balance appearance with breathability to avoid future problems.

Drying, Sanding, and Decorating Timeline

The drying process is crucial for a durable plaster repair. Here’s how to time it right:

Drying: Keep the room temperature between 50-70°F (10-21°C) and humidity around 40-60% while drying. Ventilate well, but avoid drafts that could cause rapid drying and cracks.

Sanding: After initial drying (usually 3-7 days), lightly sand with fine grit paper to remove any imperfections. Vacuum thoroughly to remove dust.

Priming & Painting: Wait for another 24 hours after sanding, then apply a primer suitable for plaster. Follow the paint manufacturer’s guidelines for recoating times.

Maintenance Tips and When to Seek Professional Help

Regular maintenance extends your repair’s lifespan:

Inspect Regularly: Check for cracks, bubbles, or peeling paint every 6 months. Use a torch to highlight any issues.

Clean Gently: Clean walls with mild detergent and water. Avoid harsh chemicals that could damage the plaster.

When to Call a Pro: If you notice large cracks, bulging, or peeling paint before it’s 5 years old, call a plastering specialist. They can assess if there’s an underlying issue needing attention.

Conclusion

Working back from a solid plaster base keeps the repair durable and the finish flat and long-lasting. The core idea is to protect the substrate, bond well, and prevent cracks before they start.

Make it happen in this order: verify the area is safe and solid, remove tile and adhesive without harming the substrate, inspect and diagnose the surface, prep exactly for a strong bond, choose the right plaster and reinforcement, mix and apply in thin, workable layers, reinforce as needed, let it dry fully, finish cleanly, and plan for maintenance so the job lasts.

Watch out for these mistakes: rushing bonding or smoothing, using the wrong plaster or missing reinforcement, and skipping tests or small-area checks that reveal substrate movement. Safety first, methodical prep, and testing a small area before full-scale work keep you from costly fixes later; never skip drying times or overtightening finishes.

If the substrate shows active movement, persistent cracks, or you’re unsure about hidden damage, stop and call a professional. When you’re comfortable with the prep and testing it’s time to proceed, stay disciplined, and you’ll end up with a flat, durable surface that takes finish well and lasts. You’ve got this—steady work today means a solid wall tomorrow.

FAQ

What should I do to surface after removing tile to prepare for plaster?

Sweep and vacuum to remove dust and debris. Wipe down with a damp cloth to pick up fine dust before plastering. If you see tile adhesive residue, plan to bond over it with a suitable primer or bonding agent per the product instructions.

How do I fix uneven spots once the tile is gone?

Identify high or low areas with a straight edge. Build up low spots with multiple thin coats of plaster, letting each coat firm up a bit before the next. For deep unevenness, consider skim coating the whole area to even out the surface.

What are good bonding techniques when tile residue remains?

Use a bonding primer or adhesion agent approved for plaster over existing tile and adhesive. Apply per the label, then press the plaster into the surface with even pressure. If the residue is flaky, remove loose bits before priming to avoid trapped air pockets.

Which plaster and primers help prevent future cracks?

Choose a plaster and primer that are compatible with the existing substrate and any residual tile glue. Follow the manufacturer’s guidance for layering and cure times. If in doubt, ask the supplier for a system that’s designed to bridge minor movement and provide reinforcement.