Introduction

Backing methods are techniques to support a plaster fill so it doesn’t shrink or crack. They create a stable base behind the hole before applying filler. When choosing a backing, check the wall type and follow safety and product instructions from the manufacturer or local rules.

Begin by cleaning the hole and exposing solid edges. Install the backing material behind the plaster, then apply the filler in thin, even passes and let each layer set. If you notice movement or edge gaps, reassess the backing and follow the product guidance for curing and finish.

Key takeaways

- Assess hole size and backing needs before chosen repair method and materials.

- Use proper adhesive and backing that resist shrinkage and align with plaster.

- Install backing in stages to avoid voids and reduce cracking risk.

- Feather joints and patch edges smoothly to blend with surrounding plaster.

- Re-check safety: wear eye protection, dust mask, and follow manufacturer instructions.

- Plan drying times around room conditions and avoid forced evaporation.

Table of Contents

- Introduction

- Key takeaways

- Why Deep Plaster Repairs Shrink and Crack

- Assessing the Hole and Planning the Repair

- Backing Methods Overview and How to Choose

- Installing Backing Correctly

- Filling Techniques That Minimize Shrinkage and Cracking

- Finishing, Feathering, and Making the Repair Invisible

- Tools and Materials Checklist

- Troubleshooting Common Problems and Long-Term Prevention

- Conclusion

- FAQ

Why Deep Plaster Repairs Shrink and Crack

Deep plaster fills are prone to movement and moisture changes that can cause shrinkage and cracking. Different materials interact at the interface, and incompatible mixes can pull away from edges as they cure. Understanding these forces helps explain why backing matters for long-term stability.

Common failure modes include separation from surrounding plaster, pinholes, and cracks that follow the underlying substrate. Recognizing how movement, moisture paths, and material compatibility contribute to failures informs the need for a proper backing system. This awareness sets the stage for selecting a durable repair approach.

Mechanics of Shrinkage and Tensile Stress

Plaster repairs in deep sections are prone to cracking due to the drying and curing processes. As plaster dries, it loses moisture and shrinks. This shrinkage creates tensile stresses, pulling the repair away from the surrounding plaster.

The deeper the section, the greater the stress. Unsupported deep sections are particularly vulnerable to these stresses, leading to cracks as the plaster tries to relieve the tension.

Understanding this helps prevent deep plaster repairs from cracking. Always consider backing methods to support the repair and mitigate tensile stress.

Substrate and Adhesion Factors

The substrate’s type, condition, and cleanliness play a crucial role in the success of your plaster repair. Different substrates may require specific preparation or adhesion methods to ensure strong bonding.

Before repairing, check the substrate type and follow recommended adhesion procedures. Contaminants like grease, paint, or loose material can hinder adhesion, increasing the risk of failure.

Proper substrate preparation ensures strong adhesion and reduces failure risk. If the substrate is unsuitable or contaminated, prepare it properly or choose an alternative repair method.

Assessing the Hole and Planning the Repair

Evaluate the hole depth, edge soundness, and the condition of the surrounding plaster. These factors guide the choice between a simple patch and a more involved repair. Consider whether the underlying wall structure shows signs of weakness or moisture.

Check for load exposure, ongoing movement, and compatibility with potential backing options. Decide if the repair can be contained with a patch or if a larger section must be replaced. Use these checks to drive a clear plan before any materials are mixed or applied.

Measuring Depth, Stability, and Access

Begin by accurately measuring the hole’s dimensions at its widest points using a ruler or tape measure. Determine the effective depth.

Inspect Behind the Plaster: Gently tap around the hole with a hammer to listen for hollow or unstable areas. If access allows, use a flashlight or mirror to thoroughly inspect the hole’s interior and assess any hidden damage.

Check the surrounding plaster for stability by gently pressing on it. If it feels soft, crumbles, or sounds hollow, investigate further for potential structural issues before proceeding with repairs.

If the hole is deep (greater than 10mm) and access to its full depth is limited, consider using a backing material to reinforce the repair. If needed, use a small endoscope camera for more precise inspection to avoid inaccurate assessments.

When to repair vs replace the board or lath

Before starting repairs, determine if localized patching is sufficient or if entire sections need replacing. Gently pull on the plasterboard or lath; if it feels loose or moves easily, replacement may be necessary.

Inspect the affected area: Look for signs of water damage, mold, or widespread cracking. If damage is localized and edges are stable, proceed with a local repair using backing material to reinforce the area.

However, if multiple holes, widespread damage, or instability is present, consider replacing the entire plasterboard/lath section to ensure lasting repairs. Consulting a professional for an expert opinion can help prevent wasted effort and further damage if you’re unsure about the extent of damage.

Backing Methods Overview and How to Choose

Rigid backing provides a solid base for large or deep voids, helping distribute load and reduce sag. Metal lath and mesh offer breathable support that can integrate with plaster finishes. Foam and temporary formwork can fill irregular shapes while maintaining spacing.

Select a backing based on depth, expected load, and moisture exposure. For heavy or damp conditions, prioritize materials with good rigidity and moisture resistance. For shallow repairs, lighter backing may be sufficient if properly secured and backed by compatible plaster.

Rigid backing (block, plywood, board)

Rigid backing is preferred for deep holes where stability and load-bearing capacity are crucial. It provides structural support to the fill, preventing shrinkage and cracking.

Key considerations include:

- Fixing: Secure rigid backing firmly to the substrate using appropriate fasteners such as screws or nails.

- Surface compatibility: Ensure the rigid backing is compatible with the plaster surface to prevent delamination.

Common mistake: Not securing rigid backing properly, leading to fill failure. Always check local building codes for specific requirements.

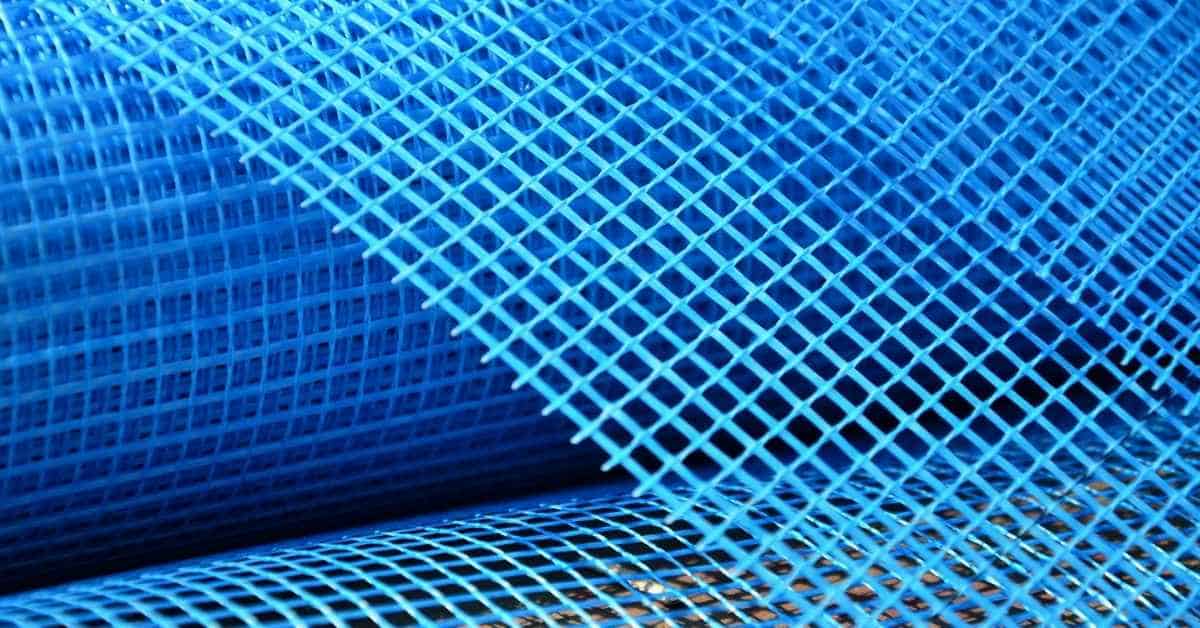

Open backing (metal lath, plaster washers, mesh)

Metal lath and mesh provide a mechanical key for base coats, improving adhesion. They are suitable for areas with high moisture exposure or where flexibility is needed.

When to use:

- High moisture exposure

- Base coat needs mechanical key

Quick check: Ensure lath/mesh is securely attached to the substrate using appropriate fasteners. Common mistake: Using open backing alone for deep fills without additional support, leading to fill failure.

Backfill and temporary formers (expanding foam, polystyrene, cardboard cones)

Backfill or temporary formers reduce fill volume, simplifying repair and preventing excessive weight. They are ideal for shallow holes or when access is limited.

Risks to avoid:

- Trapped moisture: Ensure backfill material is compatible with the plaster system being used to prevent trapping moisture.

- Incompatible adhesives: Check that the backfill material does not react negatively with the plaster or adhesive being used.

Common mistake: Not allowing backfill to cure completely before applying plaster, leading to trapped moisture and fill failure. Always follow manufacturer’s instructions for specific materials.

Installing Backing Correctly

Prepare the hole by cleaning loose debris and dampening the surface as needed. Fit the backing so it sits firmly without forcing the surrounding plaster to crack. Secure the backing following the manufacturer’s guidance or standard practices for the chosen material.

Confirm that the backing is stable and properly aligned before applying any filler. Check that edges remain supported and that there is a clear anchor for the plaster to grip. Avoid overloading adjacent surfaces during installation to prevent further movement.

Preparing the Hole and Cleaning Edges

Begin by removing any loose material from the hole using a chisel or scraper. This ensures a solid base for your backing.

If needed, create a keyed edge to improve adhesion of the backing material. Use a hammer and chisel to score the edges at 45-degree angles.

Ensure the substrate is dry before proceeding. If it’s damp, allow it to dry completely. Dust off any debris with a brush or vacuum to create a clean surface for bonding.

Fixing Rigid Backers and Attaching Lath/Mesh

For rigid backers like plywood or block, secure them using appropriate screws or nails. Ensure they are level and flush with the existing surface.

When attaching lath or mesh, cut it to size and recess it slightly into the plaster. This allows for better bonding and prevents bridging of the existing surface.

Use a lath nailer or stapler to secure the lath/mesh, ensuring it’s firmly attached but not pulling away from the substrate. Check for any gaps or loose spots and reinforce as needed.

Filling Techniques That Minimize Shrinkage and Cracking

Use the backing to reduce the effective fill depth and create a strong base for subsequent coats. Apply bonding agents only as recommended by the product instructions to improve adhesion. Build up the repair in layers to control drying stresses and avoid a single thick coat.

Follow the filler’s cure guidance and ensure compatibility with the backing and substrate. Allow each layer to set as directed and monitor for movement or soft spots. Always check labeling for mixing ratios and application limits before proceeding.

Layering and allowing proper set/cure

When filling deep holes in plaster, it’s crucial to apply materials in incremental layers or scratch coats. This technique helps limit shrinkage and prevents cracking.

Allow each layer to set and cure completely before applying the next. This gives the material time to expand and contract naturally without causing stress on the surrounding area.

If deep fills are required, use this incremental layering method. If cracking occurs, reduce the thickness of each layer and increase the cure time between applications.

Choosing compatible fillers and bonding agents

To ensure a strong bond and prevent delamination, it’s essential to match setting-type plasters, skim coats, or cementitious products with the backing and existing plaster.

Review manufacturer instructions for adhesion guidelines. If using different materials, follow these guidelines strictly to maintain compatibility.

Matching products ensures adhesion and prevents delamination, making your repair more durable and long-lasting. If delamination occurs, reapply using compatible materials and proper bonding agents.

Finishing, Feathering, and Making the Repair Invisible

Skim the surface to achieve a uniform plane with careful feathering at the edges. Blend texture to match the surrounding wall and minimize contrast that highlights the repair. Use light pressure and consistent motion to avoid creating new stress points.

Evaluate readiness for paint by looking for a stable, dry, and crack-free surface. Check that transitions to adjacent plaster are smooth and that there is no visible line. Proceed with priming and finishing steps only after the patch passes visual and tactile checks.

Skimming and Feathering Techniques

The key to an invisible repair lies in the final skim coat. Use a wide trowel (12″-14″) for this stage to ensure even application.

Feather the edges of your skim coat into the surrounding plaster using smooth, overlapping strokes. This helps prevent ridges and future cracking by gradually blending the new plaster into the old.

Pro Tip: Check for any unevenness or ridges visually before moving on to sanding. If present, re-skim and feather again until the surface is smooth and even.

Sanding, Priming, and Paint Matching

After skimming, lightly sand the repaired area using fine-grit (220-320) sandpaper. Be careful not to sand through the skim coat or create visible marks.

Apply a primer designed for your wall type to equalize suction and provide a uniform surface for painting. This helps achieve an invisible finish by preventing the new paint from absorbing differently than the surrounding area.

Pro Tip: Matching texture, color, and sheen is crucial for a seamless repair. Test different paints on a small, hidden area before applying to the entire wall. If the match isn’t perfect, re-prime and repaint, ensuring correct matching techniques are used.

Tools and Materials Checklist

Assemble essential tools for backing placement, patching, and finishing. Include items for cleaning, cutting, securing, and smoothing the plaster. Verify that each item is suitable for interior plaster work and compatible with the chosen backing.

Review product labels for compatibility, cure times, and substrate suitability. Look up manufacturer recommendations when specifics are needed and confirm any local code requirements that apply to the repair. Keep the list practical and complete before starting the job.

Essential Hand and Power Tools

Quality tools ensure a smooth, professional repair. Here are the essentials:

- Trowels (4″ to 12″): Mix, apply, and smooth fillers; select straight-edged trowels for rigid backing.

- Hawk: Holds mixed filler, allowing easy transfer to trowel. Inspect condition before use.

- Screwdrivers (flathead, Phillips): Remove old screws and install new ones in backers.

- Drill (cordless, 18V or higher): Drives screws into backers; select appropriate drill bit size. Check tool quality and suitability for task.

- Scraper: Cleans edges and removes old paint or plaster. Replace damaged tools to maintain workmanship quality.

- Stake (optional, rentable): Secures backers in place; crucial for successful repair. If using rigid backing, select trowel with straight edge.

Materials, Adhesives, and Safety Supplies

Choosing the right materials ensures a strong, lasting repair. Consider these:

- Backing Materials (plywood, board, lath): Provide support; select based on hole size and depth.

- Fillers (plaster, joint compound, spackling): Fill holes; choose low-shrinkage fillers for deep holes. If Deep hole fill, then Use filler with low shrinkage properties.

- Bonding Agents: Enhance adhesion; select based on substrate and filler type. If Working with plaster, then Choose bonding agent suitable for plaster.

- Adhesives (construction adhesive, thinset): Bond backers to wall; follow manufacturer instructions for best results.

- Personal Protective Equipment (PPE): Safety glasses, gloves, and dust mask protect from debris and chemicals. Quick check: Check expiration dates and storage conditions. Pro check: Verify compatibility with substrate and other materials used.

Troubleshooting Common Problems and Long-Term Prevention

Hairline cracks can indicate movement or inadequate bonding; identify the likely cause and adjust backing, bonding, or layering as needed. Delamination suggests a poor bond or moisture intrusion that requires remediation. Shrinkage cracks may need additional layers or backing optimization.

Implement preventive measures such as proper moisture control, compatible material choices, and sound substrate preparation. Regular maintenance checks help catch issues early and extend the life of the repair. Document any changes to help guide future projects.

Detecting and fixing early failure signs

Regularly inspect your repaired plasterwork for any signs of early failure. This helps maintain structural integrity and prevents major repairs.

Look for: hairline cracks, discoloration, or soft spots indicating delamination or moisture intrusion.

If you notice these signs within the first week, then again monthly for three months, take immediate action:

1. Re-bed the repair to ensure a solid base.

2. Add mechanical fixings like screws or nails for extra support.

3. Replace any failed fill.

Preventive Measures and Routine Checks

Maintain your repair’s longevity and avoid costly rework with regular upkeep:

- Perform visual inspections: every six months, or following significant weather changes.

- Inspect for new cracks, efflorescence (white powdery deposits), or water damage signs around the repaired area. Address any findings promptly with suitable repair methods.

- Install a movement joint, if necessary, to accommodate natural expansion and contraction, preventing future cracking.

- Implement moisture control strategies, such as proper ventilation and waterproofing, to maintain repair integrity and prevent further damage.

Conclusion

When done carefully, choosing the right backing and applying filler in proper stages protects the repair from shrinkage, cracking, and future damage while keeping the finished surface looking even and durable. Prioritize safety, test on a small area, and follow the material instructions to avoid irreversible mistakes.

To check your plan in plain terms: assess the hole, select a backing method that suits its depth and support needs, confirm the backing fits firmly, apply and cure in appropriate layers, feather the edges smoothly, and test the repair for adhesion and finish before reoccupying the space.

Common mistakes to avoid include using insufficient backing or allowing it to shift during setting, rushing the filling or skipping curing time between layers, and over-smoothing or under-finishing the surface which can lead to visible ridges or cracks later. Always wear eye protection and a dust mask, work in a ventilated area, and follow the manufacturer’s instructions for each product you use; test a small area first to confirm compatibility and performance.

If the repair plan doesn’t align with the hole’s size, backing needs, or the surrounding plaster is unstable, or if you’re unsure about moisture or structural issues, consider bringing in a professional. When you proceed with confidence, you reduce risk, save time, and improve the likelihood of a seamless result that lasts.

FAQ

What backing options work best for deep plaster holes to prevent shrinkage?

Choose backing that provides a firm base and supports the patch as it cures. Common options include rigid backing boards or wedges of compatible plaster or gypsum material placed behind the repair. Confirm compatibility with the plaster you are repairing by checking product instructions and local guidelines.

How should I prepare the hole before applying backing and filler?

Clean the hole to remove dust and loose material. Remove any loose edges and dampen the surrounding plaster slightly if the surface is very dry. Follow the manufacturer’s guidance for any primer or bonding agent required with your backing material.

How do I prevent cracking as the patch dries?

Use a backing that supports the repair from behind and apply filler in stages if needed. Monitor the patch as it cures and avoid excessive thickness in one layer. Refer to product instructions for suggested layering and curing times, and adjust based on the plaster type you are repairing.

What should I check if the repair shows signs of failure later?

Inspect for loose edges, new cracks, or shrinkage near the patch. If problems appear, verify backing stability, adhesive or bonding product compatibility, and whether the surrounding plaster needs additional reinforcement. Check labels, datasheets, and local guidelines for recommended fixes.